PET bottle washing line is a complete recycling line composed of several main machines such as a plastic water bottle crusher, label removing machine, plastic flakes washing machine, plastic dewatering machine, and so on. Its main function is to transform recycled plastic bottle waste into clean PET flakes through a series of processes. For different types of plastic bottles and processing needs, Shuliy can customize the design to meet your specific bottle recycling demands.

Why Recycle PET Bottles?

Recycling PET bottles has direct economic benefits for both recyclers and producers. Recyclers can sell the processed PET bottle flakes to producers for a profit. For producers, using recycled PET bottle flakes instead of new raw materials can significantly reduce raw material costs, especially saving money in mass production. Next, we will introduce how to recycle PET bottles

PET Bottle Flakes Production Process

- De-labeling: Remove the labels from the surface of PET bottles.

- Crushing: PET bottles with labels removed are crushed into small pieces.

- Separation of caps and flakes: The lighter caps are separated from the heavier flakes by floating and sinking separation technology.

- Hot washing: Use hot water to wash bottle pieces to remove oil and residue.

- Friction Cleaning: Further friction cleaning ensures complete removal of dirt.

- Rinsing: Rinsing with clean water to remove cleaning agents and residual impurities.

- Drying: Finally, the cleaned bottle flakes are dried to get dry PET bottle flakes.

Raw Material For PET Bottle Recycling Plant

The main raw materials of PET bottle flakes washing line are used PET bottles such as mineral water bottles, beverage bottles, cola bottles, milk bottles, plastic containers, and so on. Compressed plastic bottle bricks need to be opened with a bale opener machine before they can be crushed. These bottles are collected, sorted, and then processed through the plastic bottle recycling machine. The end product of this process is clean PET flakes.

High-Quality PET Flakes

The color of PET bottle flakes and the quality of the final product affect its price. The higher the degree of cleaning and processing, the fewer the impurities, and the higher the price of PET bottle flakes, and high-quality clear flakes are usually more expensive than colored flakes.

The bottle flakes produced by our PET bottle recycling machine can meet the standard in terms of dryness, characteristic viscosity, pH value, and impurity content.

PET Bottle Recycling Machine Introduction

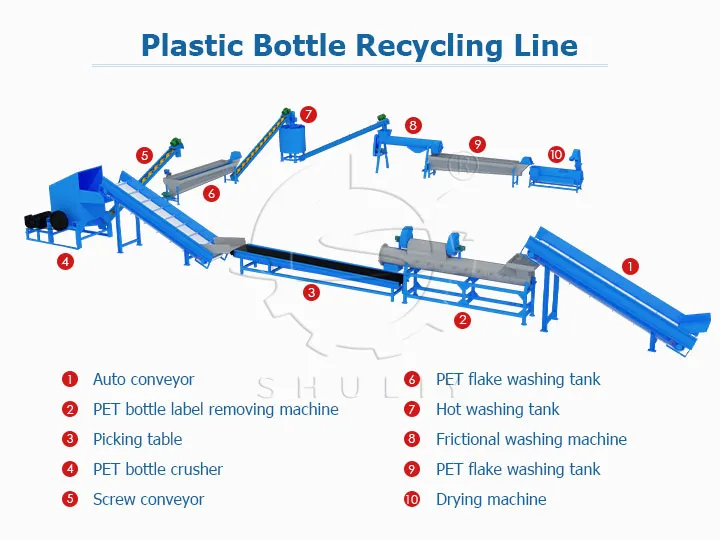

The PET bottle washing line consists of several single machines, each of which has a different role, and they work together to complete the recycling and washing process of plastic bottles.

PET Bottle Label Remover

The label remover machine has multiple carbide blades inside, removing 98% of PVC labels and reducing the PVC content in PET bottle flakes.

PET Crushing Machine

The next step was to use a PET crushing machine to crush the plastic bottles into pieces after the labels were removed. After a series of cleaning processes, these flakes become the final product we need——recycled plastic bottle flakes.

Plastic Float Sink Tank

Sink float plastic separation utilizes density to separate PET bottle flakes from PP bottle caps. The bottle flakes sink and are transported to the next process, while the cap floats and flows out.

Hot Water Washing Tank

The hot water washing tank washes plastic bottle flakes through high-temperature water and chemical detergent. This effectively removes dirt, grease, residue, and other contaminants from the surface of the bottle chips, ensuring the cleanliness of the plastic bottle chips.

Friction Washing Machine

The friction washer removes the impurities and chemical detergents attached to the bottle flakes to meet the recycling standards for reclaimed bottle flakes.

Plastic Chips Dryer Machine

This plastic dewatering machine can remove 95%-98% of water, and with drying pipes at the back, the water can be further controlled at 0.5-1%.

Video of PET Bottle Washing Line

FAQ About Plastic Bottle Recycling Machine

What Is The Output Range of The Plastic Bottle Recycling Plant?

The standard output of this PET bottle washing line ranges from 500 kg/h to 6000 kg/h.

What Are The Plant Area Requirements For This Production Line?

500 to 1000 square meters. Production lines with large volumes require a larger area.

How To Install The PET Bottle Recycling Machine?

We offer online instruction or on-site assistance with installation.

What Countries Has The Equipment Been Exported To?

Our PET bottle washing line has been exported to Nigeria, South Sudan, Mozambique, Congo, Kenya, Tanzania, Iraq, Saudi Arabia and other countries.

Benefits of Shuliy PET Bottle Washing Line

- The PET bottle flakes produced are of high quality and can be used directly in the production of plastic products.

- The entire PET bottle washing line supports a customized design, which can flexibly adapt to the customer’s plant layout and production needs.

- With the high degree of automation, a 1000kg/h production line requires only 6-8 manual operations, significantly reducing labor costs, while improving production efficiency.

Recycling Project Display

Customers from Mozambique, Congo, and Kenya have purchased PET bottle washing lines from our company. They were facing challenges in recycling waste plastic bottles. Our plastic bottle recycling machine provided them with a sustainable solution that helped them solve this problem.