The waste film recycling line is a solution designed to recycle waste PP PE LDPE HDPE film. Through a series of process steps, the production line can efficiently crush and clean waste plastic films to obtain clean film fragments.

These fragments can be further pelletized and ultimately processed into high-quality recycled plastic pellets, which are suitable for the production of a wide range of plastic products.

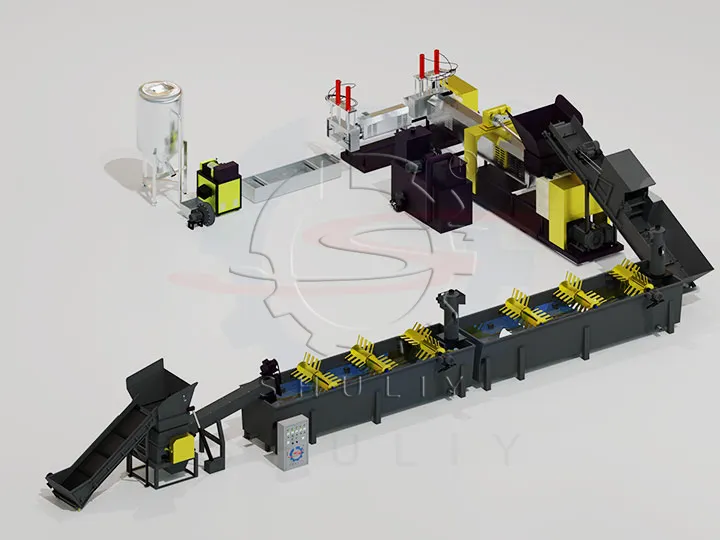

The plastic film recycling line is designed to be flexible and can be customized and configured according to customer needs to achieve optimal recycling results and production efficiency.

Introduction of Waste Film Recycling Line

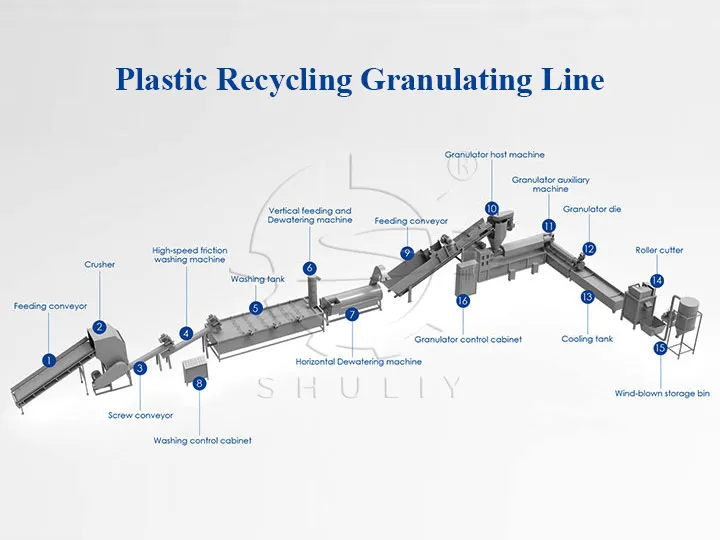

The PE PP film washing line specializes in recycling all kinds of waste films and bags. The whole granulation line consists of a plastic scrap shredder, plastic washing machine, vertical dewatering machine, pelletizing machine, cooling tank, pellet cutter machine, and storage silo. The output of the line is from 100kg/h to 500kg/h. If you need larger output we can also customize it for you.

Advantages of Film Recycling Machine

- Wide application: It is suitable for all kinds of waste plastic film materials, such as waste agricultural film, tonnage bags, stretch film, and so on.

- High-quality output: recycled pellets are of consistent quality and are suitable for a wide range of downstream products.

- Optimized design: Each machine in the production line is specially designed to increase productivity and stability.

- Customized service: We can provide customized production line configuration and direction design according to the customer’s raw material type, output requirement, plant area, and layout.

Application of Plastic Recycling Granulating Line

Raw materials that can be recycled by waste film recycling lines include LDPE agricultural film, mulch film, greenhouse film, stretch film, HDPE edging bags, woven bags, non-woven bags, raffia bags, shrink wrap, rubbish bags, bubble wrap, in-house (post-industrial) film waste, jumbo bags, drip irrigation belt, and a variety of composite and laminated films.

Final Product: Plastic Granules

The plastic pellets obtained after processing in our waste film recycling line are strong and uniform. The recycled film granules can be used in blown film, injection molding, and other processes to produce new plastic products.

waste Film Recycling Line Working Process

The plastic recycling granulating line is a comprehensive production line designed to efficiently and environmentally process waste plastic film into reusable plastic pellets. Here is the working process:

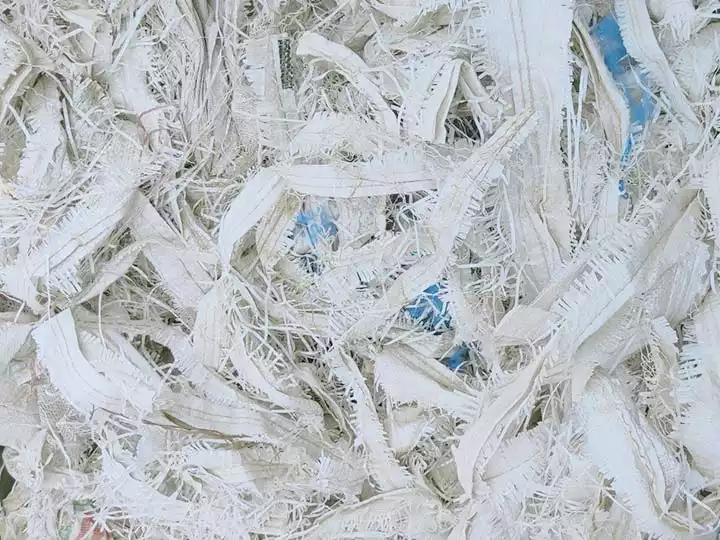

NO.1 Crushing

The waste film is first fed into a shredder machine. The plastic waste shredder machine is responsible for crushing large pieces of waste plastic film. This step is designed to reduce the size of the plastic, making it easier to pelletize.

NO.2 Washing

The crushed plastic flakes enter the plastic washing machine. This machine washes the film pieces with water to remove impurities, dirt, and residue from them.

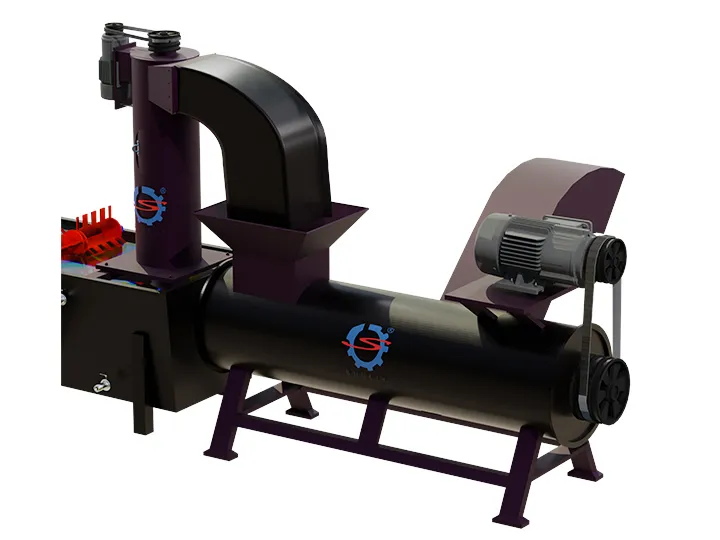

NO.3 Drying

The cleaned plastic pieces then enter the plastic dewatering machine, which removes moisture and ensures that the subsequent pelletizing process can be carried out efficiently.

NO.4 Granulation

The dried plastic fragments enter the plastic pelletizer machine, where they are heated, melted, and extruded from the die head into long continuous plastic strips.

NO.5 Cooling

After pelletizing, plastic strips will soften due to high temperatures and will not be able to be cut with a pellet cutter machine. A cooling process is therefore required to ensure that they remain in a stable form.

NO.6 Cutting & storage

The cooled plastic strips are cut into uniform plastic pellets. Finally, these plastic pellets are collected and packaged as needed for transportation and storage.

Video of waste film Pelletizing

FAQ About PE PP Film Washing Line

Q: What is the capacity of this LDPE film washing line?

A: The capacity of our waste film recycling line can be customized according to your needs, usually from a few hundred kilograms to several tons.

Q: Can you customize the soft plastic granulation line to fit my factory space and equipment configuration?

A: Yes, we can customize a waste film recycling line to meet your requirements according to your factory space and specific needs.

Q: How to install the PE PP film washing line??

A: We provide online installation guidance, and can also arrange for engineers to assist with installation on-site if customers need.

Q: What is the overall investment cost of this LDPE film washing line?

A: The overall investment cost will be affected by several factors, including production capacity, customization requirements, and so on. We will provide a detailed quotation based on your specific needs.

Q: Do you provide training on the operation of the waste film recycling line?

A: Yes, we will provide professional operation training for your staff to ensure that they can skillfully operate the whole soft PVC granulation line.

Unique Design of Film Recycling Machine

| Equipment Name | Instructions |

| Plastic recycling shredder | Blade material: 60Si2Mn Sieve mesh aperture: 40-50mm Internal water can be added A fan can be added |

| Plastic washing tank | Length: customizable Material: carbon steel Thickness: 5mm Drainage opening: 200mm large diameter With paddle wheels |

| Plastic scrap dryer machine | Vertical and horizontal can be used together Removes 95%-98% of water Avoids large amounts of smoke during pelletizing |

| Strand pelletizing system | Conveyor belt with separator With force feeder Wide range of heating methods and die heads Models are named by screw length Water ring pelletizing is available |

| Cooling tank | Stainless steel Length can be customized |

| Strip blowing machine Strip shaking machine | Removes moisture from plastic strips Prevents sticking Configuration on demand |

| Pellt cutting machine | Carbide hob Particle size 3 mm |

| Vibrating screen | Prevents pellets from sticking Filters agglomerated granules Configuration on demand |

Get PE PP Film Washing Line Price

The price of the waste film recycling line varies depending on the configuration. Prices range from a few thousand dollars to tens of thousands of dollars. Please leave a message on our website with your raw materials and needs, and we will recommend the right machine model and capacity for you.