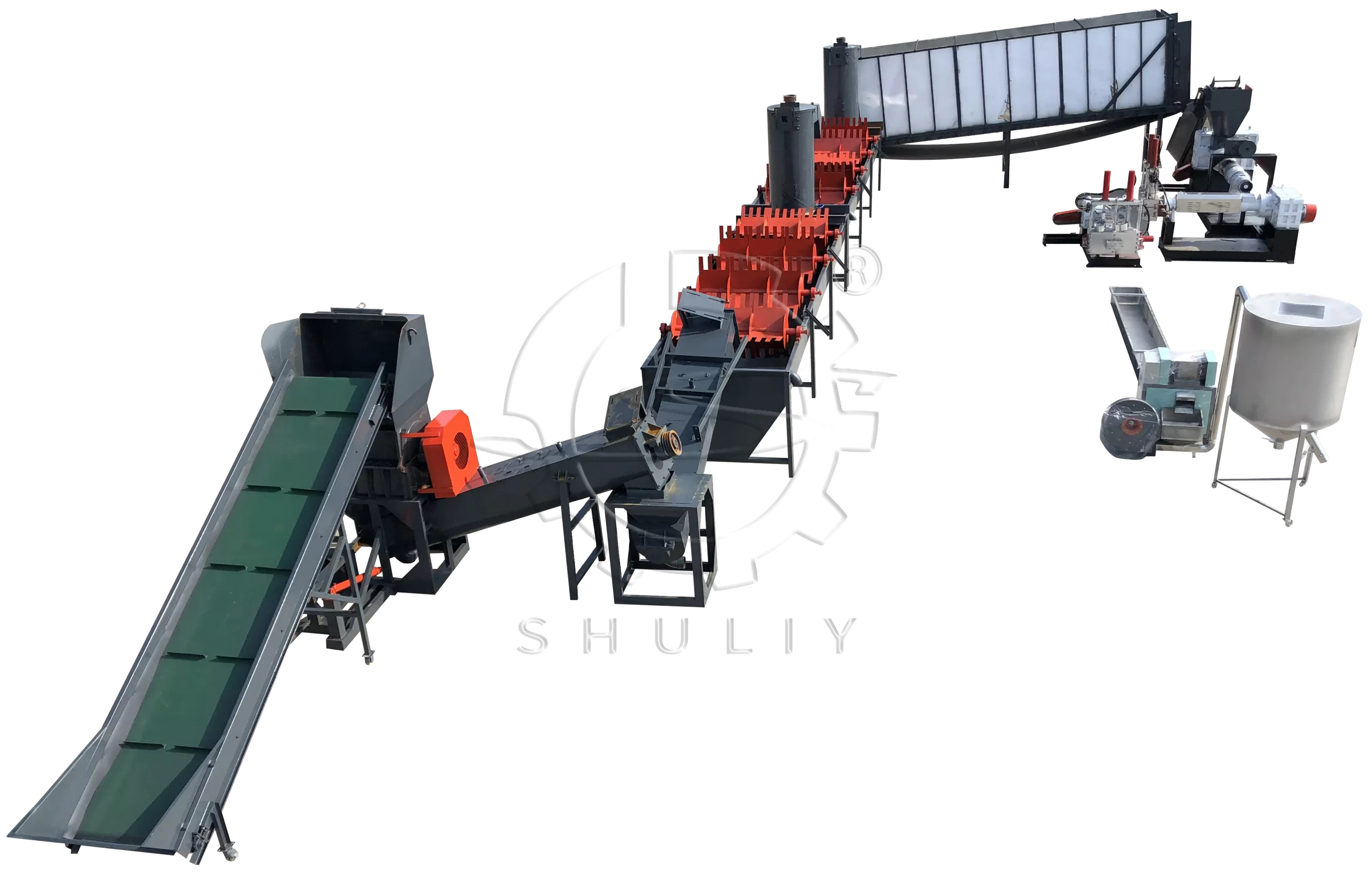

Our PE plastic flake pelletizing lines provide quick and easy plastic pollution solutions for recycling dirty rigid plastics (e.g. HDPE bottles, furniture casings, pipes, etc.). Rigid plastics are cleaned and pelletized using efficient recycling machinery connected by a series of conveyors. The end product is a completely clean plastic pellet that can be reused in manufacturing. Our PP PE flake recycling lines have capacities ranging from 200 kg/h to 2000 kg/h.

While our standard rigid PE plastic flake pelletizing lines are sufficient for most facilities, customized setups with additional configurations of machinery and increased throughput can be designed to meet your specific needs. Contact us for more information on customized recycling projects!

Row material and final product

Rigid plastics that can be processed in a plastic recycling line include plastic drums, plastic basins, plastic pallets, plastic toys, furniture and appliance shells, plastic chairs, and more. The final product is plastic pellets that can be used to make new plastic products.

Final product made from PP PE flake recycling line

Finalized plastic pellets are used in a variety of industries, including plastics manufacturing, construction, and packaging. They are used as a valuable raw material in the production of a wide range of plastic products.

PE plastic flake pelletizing line process

| NO. | Process | Machine | Description |

| 1 | Linking the individual machines and conveying the raw materials. | Conveyor belt | This seamless transfer ensures continuous and efficient recovery. |

| 2 | Crushes plastic into small pieces that are easy to pelletize. | Plastic crushing machine | This step is crucial for subsequent pelletizing, as large pieces of plastic cannot be put into the plastic pelletizer. |

| 3 | Cleaning of plastic waste after the shredder | Plastic washing machine | Remo val of impurities, contaminants and residual material ensures high quality of the final plastic pellet. |

| 4 | Removing water from recycled plastics | Dewatering machine | To prevent adverse effects on the plastic pelletizing process |

| 5 | Extruding crushed plastic into plastic strips | Plastic granules making machine | Melt and extrude the plastic. The plastic pelletizer is the heart of the entire recycling process. |

| 6 | Cool down the extruded plastic strip. | Cooling tank | High-temperature plastic strips cannot be cut and need to be cooled and solidified first. |

| 7 | Cut cooled plastic strips into uniformly sized plastic pellets. | Granules cutting machine | Homogeneous plastic pellets are of good quality and high price. |

PE plastic flake pelletizing line main machine show

FAQ about PE plastic flake pelletizing line

Q: Can this PE plastic flake pelletizing line handle other types of plastics?

A: The PP PE flake recycling line is specifically designed to recycle rigid plastics. For other types of plastics, different recycling equipment may be required.

Q: What is the production capacity of the rigid PVC granulation line?

A: Production capacity may vary depending on factors such as plastic recycling granulating line specifications and operating conditions. Shuliy can customize your rigid PVC granulation line output.

Q: Is this PE plastic flake pelletizing line easy to operate and maintain?

A: Yes, our PP PE flake recycling line is designed to be user-friendly and easy to maintain with a detailed instruction manual provided.

Q: Can I customize this rigid PVC granulation line to meet specific production requirements?

A: Yes, we offer customization options to tailor the plastic recycling granulating line to your specific needs and production goals.

Get PP PE flake recycling line price

To get the latest prices and delivery times for the PE plastic flake pelletizing line, please message us on the website.