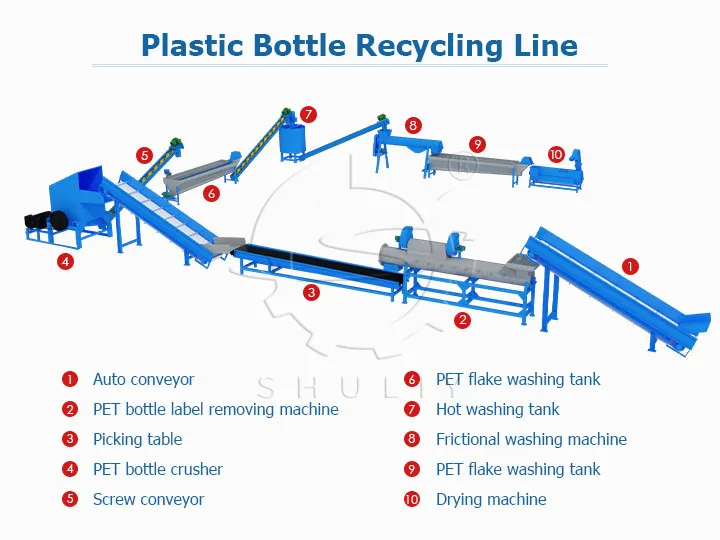

PET bottle washing line is a complete recycling line composed of several main machines such as a plastic water bottle crusher, label removing machine, plastic flakes washing machine, plastic dewatering machine, and so on. Its main function is to transform recycled plastic bottle waste into clean PET flakes through a series of processes. For different types of plastic bottles and processing needs, Shuliy can customize the design to meet your specific bottle recycling demands.

Introduction of PET bottle washing line

The plastic bottle recycling line is a recycling solution specifically designed to efficiently recycle and process plastic bottles. It consists of a series of interlinked machines working together to convert waste bottles into high-quality recycled plastic flakes.

Shuliy is a specialized PET bottle washing line manufacturer and has helped several countries such as Kenya, Congo, Mozambique, and others with their plastic bottle recycling projects. These customers have set up PET bottle recycling plants and are making profits from these recycling projects.

Row material for PET bottle recycling plant

The main raw materials of PET bottle flakes washing line are used PET bottles such as mineral water bottles, beverage bottles, cola bottles, milk bottles, plastic containers, and so on. Compressed plastic bottle bricks need to be opened with a bale opener machine before they can be crushed. These bottles are collected, sorted, and then processed through the plastic bottle recycling machine. The end product of this process is clean PET flakes.

Working principle

The PET bottle washing line consists of several single machines, each of which has a different role, and they work together to complete the recycling and washing process of plastic bottles.

Plastic label remover

The first step in recycling plastic bottles is to remove the trademark paper from them. These labels are made of PVC and need to be peeled off the plastic bottles with a plastic label remover.

PET crushing machine

The next step was to use a PET crushing machine to crush the plastic bottles into pieces after the labels were removed. After a series of cleaning processes, these flakes become the final product we need——recycled plastic bottle flakes.

Plastic float sink tank

The plastic float rinsing tank can, on the one hand, separate the PET flakes that sink to the bottom of the water and the PVC labels that float on the water surface, and on the other hand, it can initially remove the impurities from the PET flakes.

Hot water washing tank

The hot water washing tank washes plastic bottle flakes through high-temperature water and chemical detergent. This effectively removes dirt, grease, residue, and other contaminants from the surface of the bottle chips, ensuring the cleanliness of the plastic bottle chips.

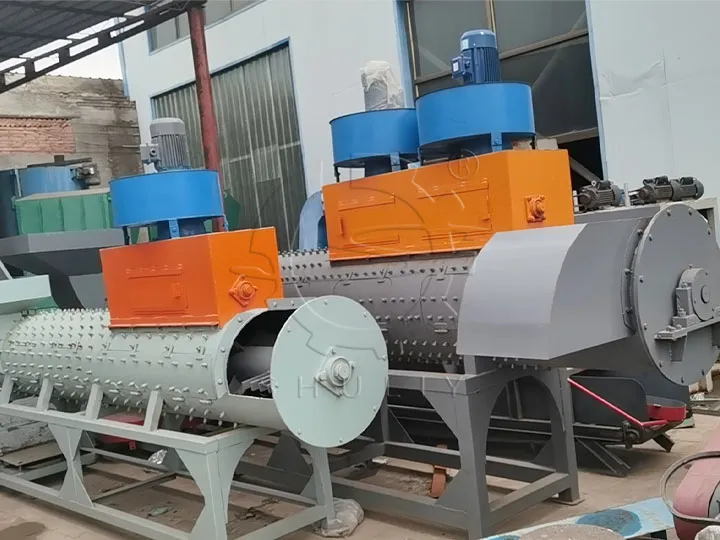

Friction washing machine

The friction washer removes the impurities and chemical detergents attached to the bottle flakes to meet the recycling standards for reclaimed bottle flakes. This is also the last washing process.

Plastic chips dryer machine

The plastic chips dryer machine removes the water that remains after the bottle flakes have been cleaned. The dried bottle flakes can be directly bagged and stored. This is the last process in the PET bottle washing line.

Video of PET bottle washing line

FAQ about plastic bottle recycling machine

- Q: Is the PET bottle washing line suitable for different types of plastic bottles?

A: Yes, our PET bottle washing line can handle many types of plastic bottles, including beverage bottles, coke bottles, milk bottles, and so on. It is highly versatile and can adapt to different types of raw materials. - Q: Does the running process of the plastic bottle recycling line need personnel to operate?

A: Yes. Although PET bottle washing line can realize fully automatic production, it needs workers to start and supervise it. We will provide appropriate training to ensure that the operators can master the use of the PET bottle flakes washing line. - Q: How to control the humidity of PET bottle flakes after washing?

A: PET bottle washing line is equipped with efficient drying equipment, which can control the humidity of PET bottle flakes in a suitable range after washing. - Q: What is the energy consumption of plastic bottle recycling machines?

A: Our PET bottle washing line adopts advanced energy-saving technology to minimize energy consumption through optimized design and high-efficiency equipment. - Q: What is the processing capacity of a PET bottle recycling plant?

A: The processing capacity of the PET bottle recycling plant can be customized according to the customer’s demand, usually ranging from 200kg/h to 3000kg/h. - Q: Can I enjoy the after-sales service after purchasing a PET bottle washing line?

A: Of course you can. We provide a full range of after-sales services, including plastic bottle recycling machine installation and commissioning, operation training, regular maintenance, and so on.

Benefits of Shuliy PET bottle washing line

- The plastic bottle recycling line adopts advanced technology and automation control systems, which can realize high production and processing capacity and enhance production efficiency.

- PET bottle recycling plant usually includes crushing, cleaning, granulating, and other links, which can complete multiple processes and realize integrated operation, reducing the complexity of the production process.

- PET bottle flakes washing line is equipped with an advanced control system, which can accurately control the parameters of each process, ensuring the stability and quality of the production process.

- For different types of plastic bottles and processing needs, we can customize the design to meet your specific production requirements.

Recycling project display

Customers from Mozambique, Congo, and Kenya have purchased PET bottle washing lines from our company. They were facing challenges in recycling waste plastic bottles. Our plastic bottle recycling machine provided them with a sustainable solution that helped them solve this problem.

500 kg/h plastic bottle recycling line data

- Power: 22kw

- Capacity: 500kg/h

- Size: 1100*1400*1600mm

- Crusher blade: 10pcs( material 9Cr Si)

- Power:15kw+3kw

- Size:4300*1000*1600 mm

- Weight:2600kg

- Power: 3kw

- Size: 5000*1000*1000mm