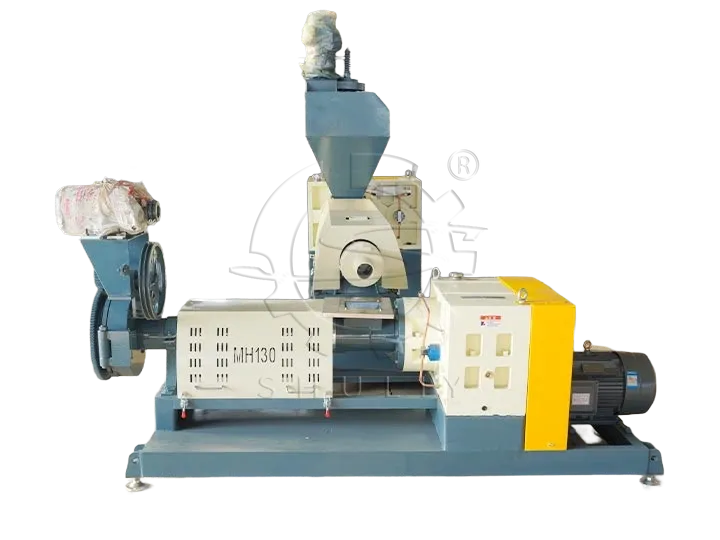

Waste plastic granulator machine is an indispensable piece of equipment in plastic recycling processing. Its main function is to convert waste plastics made of polypropylene (PP), polyethylene (PE), and low-density polyethylene (LDPE) into plastic pellets.

What is waste plastic granulator machine?

Plastic granulating machine is a kind of recycling equipment designed for processing waste plastics. Its function is to transform the originally scattered waste plastics into plastic granules through melting, extruding, cooling, cutting, and other processes.

These pellets can be reused in the production of plastic products. Different types of pelletizing recycling machines have different working principles and uses. However, they all share the common goal of processing waste plastic into reusable plastic pellets.

Raw materials and final products

The waste plastic granulator machine specializes in processing a wide range of plastic materials, including plastic film, agricultural film, mulch film, woven bags, garbage bags, cling film, stretch film, trellis film, and so on.

Plastic films are light and not easy to feed. It is usually necessary to install an automatic feeder machine on the plastic dana making machine to assist in feeding. The finished product after processing is a high-quality plastic granules.

How does plastic granulating machine work?

The machine structure of a plastic dana making machine mainly includes key components such as a hopper, screw, barrel, heating device, mold head, and control panel.

- The hopper is responsible for storing and loading the plastic raw materials to be processed.

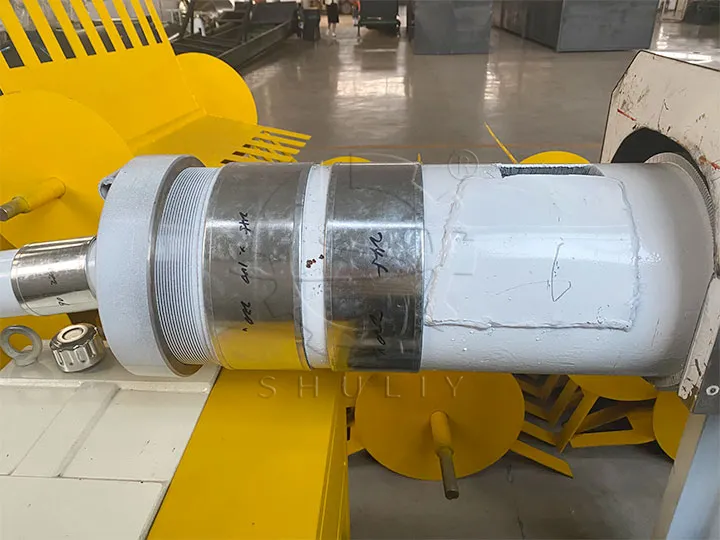

- The screw of pelletizing recycling machine is the core component that pushes, extrudes, melts, and compacts the plastic row material into granular form through rotary motion.

- The barrel provides heating and internal pressure support, while the heating unit provides the required heating temperature on the outer wall of the barrel.

- A die head is used to mold the plastic pellets to a specific shape and size.

- The control panel is used to set and regulate the operating parameters of the pelletizer, such as temperature, speed, etc.

Plastic granulating machines are usually used with other machines to form a complete plastic pelletizing line. Some plastic raw materials are dirty and large, and they need to be crushed and cleaned first.

3 heating methods for plastic dana making machine

Shuliy plastic dana making machine offers three different heating methods:

- Electromagnetic heating: this method utilizes electromagnetic heating to generate heat and ensure efficient melting and extrusion.

- Electric heating: Electric heating coils are used to provide stable and controllable heat, which is suitable for all kinds of plastics in the pelletizing process. Plastic recycling pelletizer auxiliaries are generally heated electrically.

- Ceramic Heating: Ceramic heating elements have excellent thermal conductivity, enabling precise temperature control during the pelletizing process.

Plastic granulation temperature

The pelletizing temperature of plastic films usually depends on the type and properties of the specific plastic material used, as well as the model and design of the waste plastic granulator machine.

In general, common plastic film materials such as PE and PP are typically pelletized at temperatures between 180°C and 240°C.

In addition, depending on the properties of the plastic, such as melting point and melt index, small-scale tests can also be carried out to determine the optimum extrusion pelletizing machine heating temperature.

Video about plastic recycling pelletizer

FAQ on extrusion pelletizing machine

- Q: What types of plastic materials can the waste plastic granulator machine handle?

A: The pelletizing recycling machine is designed to process a wide range of plastic materials, including PP, PE, and other films and bags. - Q: How can I ensure the quality of the plastic pellets produced?

A: Adjusting the proper temperature settings and regular maintenance of the plastic granulating machine will ensure a consistently high-quality pellet output. - Q: Is the waste plastic granulator machine easy to operate and maintain?

A: Yes, our plastic dana making machines are designed to be user-friendly and require only simple regular maintenance.

4. Q: Can the extrusion pelletizing machine handle large quantities of plastic scrap?

A: Yes, our machines are suitable for small-scale operations as well as capable of handling large-scale plastic recycling operations with a high degree of flexibility.

5. Q: How do I choose the right model of plastic granulating machine for me?

A: Choosing the right model for waste plastic granulator machines needs to take into account the type of raw material, output demand, working environment, and other factors. Our technical team can provide professional advice based on your specific situation to ensure that the most suitable model is selected.

6. Q: What is the capacity of a waste plastic granulator machine?

A: The capacity depends on the machine model and the type of raw material. The output of our waste plastic granulator machine is about 200kg/h to 2000kg/h. If you need a larger output granulator, we can also customize it for you.

7. Q: Do you provide installation and commissioning services?

A: Yes, we can provide installation, commissioning, and training services to ensure that the plastic dana making machine is properly commissioned in your plant.

Our technical team will provide you with professional technical guidance and training to ensure that you can skillfully operate and maintain the equipment.

Successful cases of plastic granulating machine

Our waste plastic granulator machines have been exported to Germany, Mozambique, Sri Lanka, Saudi Arabia, Cote d’Ivoire, and other countries. This internationalized performance fully proves the reliability and efficiency of our machines.

If you are also engaged in the plastic recycling business, please leave your message on our website and we will recommend the most suitable pelletizing recycling machine for you.

SL-150 pelletizing recycling machine information

| Name | Host plastic granulating machine | Name | Second plastic granulating machine |

| Model | SL-150 | Model | SL-150 |

| Power | 37kw | Power | 15kw |

| Screw | 2m | Screw | 1m |

| Heating method | Electromagnetic heating | Heating method | Heating ring |