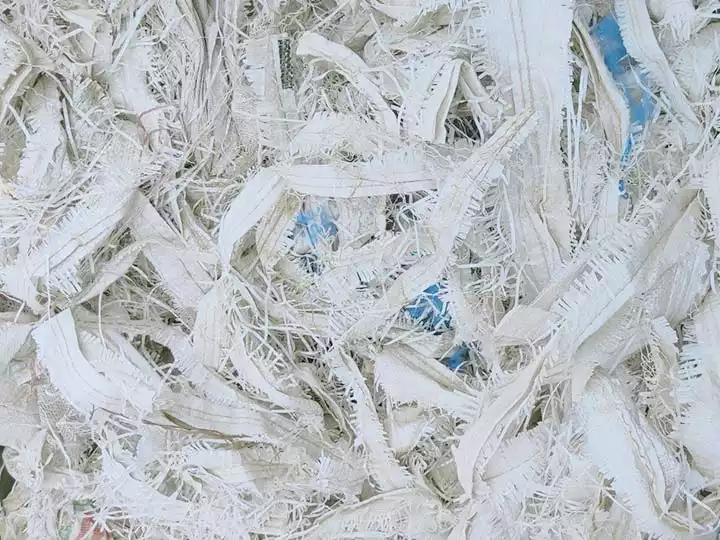

Mstari wa kuchakata filamu taka ni suluhisho iliyoundwa kusaga taka filamu ya PP PE LDPE HDPE. Kupitia mfululizo wa hatua za mchakato, laini ya uzalishaji inaweza kuponda na kusafisha filamu taka za plastiki ili kupata vipande safi vya filamu.

Vipande hivi vinaweza kupigwa zaidi na hatimaye kusindika kwenye vidonge vya plastiki vilivyotengenezwa kwa ubora wa juu, ambavyo vinafaa kwa ajili ya uzalishaji wa aina mbalimbali za bidhaa za plastiki.

Laini ya kuchakata filamu ya plastiki imeundwa kunyumbulika na inaweza kubinafsishwa na kusanidiwa kulingana na mahitaji ya mteja ili kufikia matokeo bora ya urejeleaji na ufanisi wa uzalishaji.

Utangulizi wa Mstari wa Urejelezaji wa Filamu Takataka

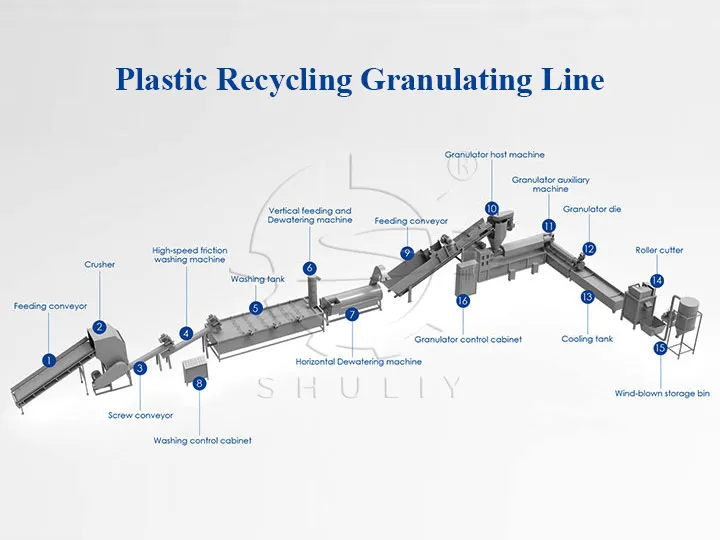

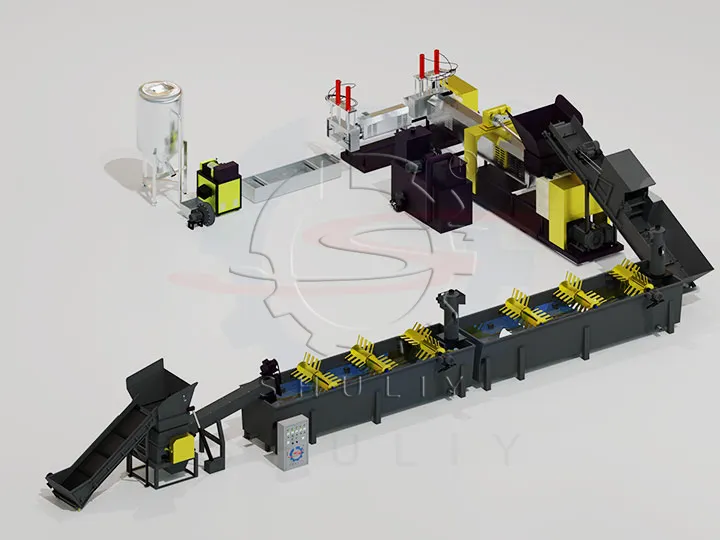

Laini ya kuosha filamu ya PE PP ina utaalam wa kuchakata kila aina ya filamu na mifuko ya taka. Laini nzima ya chembechembe ina shredder ya plastiki, mashine ya kuosha plastiki, mashine ya kuondoa maji wima, mashine ya kusaga, tanki la kupoeza, mashine ya kukata pellet, na silo ya kuhifadhi. Pato la mstari ni kutoka 100kg / h hadi 500kg / h. Ikiwa unahitaji pato kubwa tunaweza pia kukuwekea mapendeleo.

Manufaa ya Mashine ya Urejelezaji Filamu

- Programu pana: Inafaa kwa kila aina ya vifaa vya filamu vya plastiki, kama vile filamu ya kilimo taka, mifuko ya tani, filamu ya kunyoosha, na kadhalika.

- Pato la ubora wa juu: pellets zilizorejeshwa zina ubora thabiti na zinafaa kwa anuwai ya bidhaa za chini ya mkondo.

- Muundo ulioboreshwa: Kila mashine katika mstari wa uzalishaji imeundwa mahsusi ili kuongeza tija na utulivu.

- Huduma iliyobinafsishwa: Tunaweza kutoa usanidi wa mstari wa uzalishaji uliobinafsishwa na muundo wa mwelekeo kulingana na aina ya malighafi ya mteja, mahitaji ya pato, eneo la mmea, na mpangilio.

Utumiaji wa Mstari wa Urejelezaji wa Plastiki wa Kuchakata

Malighafi zinazoweza kusindika tena kwa njia za kuchakata filamu taka ni pamoja na filamu ya kilimo ya LDPE, filamu ya matandazo, filamu ya chafu, filamu ya kunyoosha, mifuko ya HDPE ya kuning'inia, mifuko ya kusuka, mifuko isiyo ya kusuka, mifuko ya raffia, kanga, mifuko ya takataka, vifuniko vya mapovu, ndani. taka za filamu za nyumbani (baada ya viwanda), mifuko ya jumbo, ukanda wa umwagiliaji kwa njia ya matone, na aina mbalimbali za filamu zenye mchanganyiko na laminated.

Bidhaa ya Mwisho: Granules za Plastiki

Vidonge vya plastiki vilivyopatikana baada ya usindikaji katika mstari wetu wa kuchakata filamu taka ni nguvu na sare. Chembechembe za filamu zilizorejelewa zinaweza kutumika katika filamu iliyopulizwa, ukingo wa sindano, na michakato mingine kuzalisha bidhaa mpya za plastiki.

taka Mchakato wa Kufanya Kazi wa Usafishaji Filamu

Laini ya kuchakata chembechembe za plastiki ni njia ya kina ya uzalishaji iliyoundwa kwa ufanisi na kimazingira kusindika taka za filamu za plastiki kuwa pellets za plastiki zinazoweza kutumika tena. Hapa kuna mchakato wa kufanya kazi:

NO.1 Kuponda

Filamu ya taka ni ya kwanza kulishwa kwenye mashine ya shredder. The mashine ya kuchambua taka za plastiki ni wajibu wa kuponda vipande vikubwa vya filamu taka ya plastiki. Hatua hii imeundwa ili kupunguza ukubwa wa plastiki, na kuifanya iwe rahisi kwa pellets.

NO.2 Kuosha

Vipande vya plastiki vilivyovunjwa vinaingia mashine ya kuosha plastiki. Mashine hii huosha vipande vya filamu na maji ili kuondoa uchafu, uchafu na mabaki kutoka kwao.

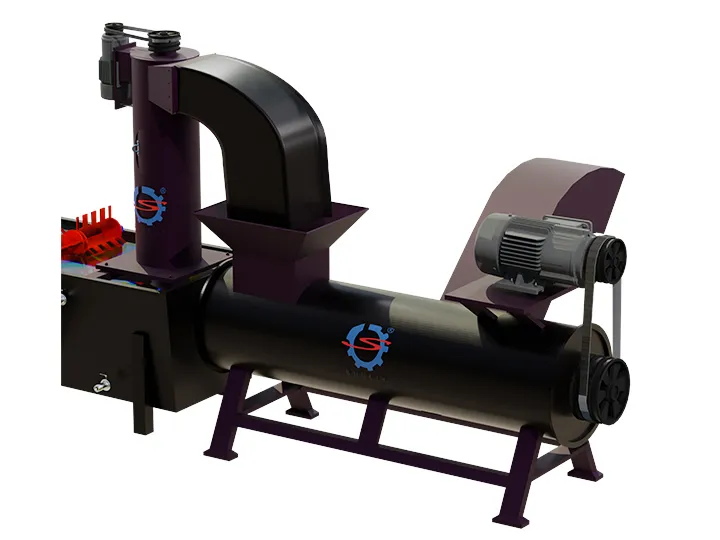

NO.3 Kukausha

Vipande vya plastiki vilivyosafishwa kisha ingiza mashine ya kuondoa maji ya plastiki, ambayo huondoa unyevu na kuhakikisha kwamba mchakato wa pelletizing unaofuata unaweza kufanyika kwa ufanisi.

NO.4 Granulation

Vipande vya plastiki vilivyokaushwa huingia mashine ya plastiki ya pelletizer, ambapo hupashwa moto, kuyeyushwa, na kutolewa kutoka kwenye kichwa hadi kwenye vipande virefu vya plastiki vinavyoendelea.

NO.5 Kupoeza

Baada ya kunyunyiza, vipande vya plastiki vitapungua kwa sababu ya joto la juu na haitaweza kukatwa na a mashine ya kukata pellet. Kwa hiyo mchakato wa baridi unahitajika ili kuhakikisha kuwa wanabaki katika fomu imara.

NO.6 Kukata & kuhifadhi

Vipande vya plastiki vilivyopozwa hukatwa kwenye vidonge vya plastiki sare. Hatimaye, pellets hizi za plastiki hukusanywa na kufungwa kama inavyohitajika kwa usafiri na kuhifadhi.

Video ya taka filamu Pelletizing

Maswali Yanayoulizwa Mara kwa Mara Kuhusu Laini ya Kuosha Filamu ya PE PP

Swali: Je, laini hii ya kuosha filamu ya LDPE ina uwezo gani?

A: Uwezo wa laini yetu ya kuchakata filamu taka inaweza kubinafsishwa kulingana na mahitaji yako, kwa kawaida kutoka kilo mia chache hadi tani kadhaa.

Swali: Je, unaweza kubinafsisha laini laini ya granulation ili kutoshea nafasi yangu ya kiwandani na usanidi wa vifaa?

Jibu: Ndiyo, tunaweza kubinafsisha laini ya kuchakata filamu taka ili kukidhi mahitaji yako kulingana na nafasi ya kiwanda chako na mahitaji mahususi.

Swali: Jinsi ya kufunga mstari wa kuosha filamu ya PE PP?

J: Tunatoa mwongozo wa usakinishaji mtandaoni, na pia tunaweza kupanga wahandisi kusaidia usakinishaji kwenye tovuti ikiwa wateja watahitaji.

Swali: Gharama ya jumla ya uwekezaji wa laini hii ya kuosha filamu ya LDPE ni nini?

J: Gharama ya jumla ya uwekezaji itaathiriwa na mambo kadhaa, ikiwa ni pamoja na uwezo wa uzalishaji, mahitaji ya ubinafsishaji, na kadhalika. Tutatoa dondoo ya kina kulingana na mahitaji yako maalum.

Swali: Je, unatoa mafunzo juu ya uendeshaji wa njia ya kuchakata filamu taka?

Jibu: Ndiyo, tutatoa mafunzo ya utendakazi wa kitaalamu kwa wafanyakazi wako ili kuhakikisha kwamba wanaweza kuendesha kwa ustadi laini nzima ya granulation ya PVC.

Muundo wa Kipekee wa Mashine ya Urejelezaji Filamu

| Jina la Kifaa | Maagizo |

| Shredder ya kuchakata plastiki | Nyenzo za blade: 60Si2Mn Ungo wa matundu ya ungo: 40-50mm Maji ya ndani yanaweza kuongezwa Shabiki anaweza kuongezwa |

| Tangi ya kuosha plastiki | Urefu: unaweza kubinafsishwa Nyenzo: chuma cha kaboni Unene: 5 mm Ufunguzi wa mifereji ya maji: kipenyo kikubwa cha 200mm Na magurudumu ya paddle |

| Mashine ya kukausha chakavu cha plastiki | Wima na usawa inaweza kutumika pamoja Huondoa 95%-98% ya maji Epuka kiasi kikubwa cha moshi wakati wa pelletizing |

| Mfumo wa pelletizing wa kamba | Ukanda wa conveyor na kitenganishi Na feeder ya nguvu Mbinu mbalimbali za kupokanzwa na vichwa vya kufa Mifano zinaitwa kwa urefu wa screw Pelletizing ya pete ya maji inapatikana |

| Tangi ya baridi | Chuma cha pua Urefu unaweza kubinafsishwa |

| Mashine ya kupuliza kamba Mashine ya kutikisa strip | Huondoa unyevu kutoka kwa vipande vya plastiki Inazuia kushikamana Usanidi kwa mahitaji |

| Mashine ya kukata pell | Hobi ya Carbide Ukubwa wa chembe 3 mm |

| Skrini inayotetemeka | Inazuia pellets kutoka kwa kushikamana Huchuja chembechembe zilizokusanywa Usanidi kwa mahitaji |

Pata Bei ya Kuosha Filamu ya PE PP

Bei ya laini ya kuchakata filamu taka inatofautiana kulingana na usanidi. Bei huanzia dola elfu chache hadi makumi ya maelfu ya dola. Tafadhali acha ujumbe kwenye tovuti yetu ukiwa na malighafi na mahitaji yako, na tutakupendekezea mtindo na uwezo sahihi wa mashine.