Plastic pelletizing machine is mainly used for processing industrial and agricultural plastic scraps. Plastic granules extruder machines have special screw designs and different configurations, models include single-screw strand pelletizer machines, twin-screw strand pelletizer machines, and so on. Each plastic pelletizing machine can be equipped with different heating rings and die heads according to pelletizing requirements. The plastic pelletizing machine is suitable for the regeneration granulation of the most common rigid scrap plastics such as HDPE, ABS, PA, PVC, PC, and other plastics.

Introduction of plastic pelletizing machine

The strand pelletizer machine is the most important machine in the waste plastic recycling line. It converts waste plastic into recycled plastic pellets. Different models of HDPE pelletizing machines have different outputs. Shuliy can provide plastic granules extruder machines with outputs ranging from 200kg/h to 1000kg/h. Of course, if you need a larger capacity, we can customize it for you.

Raw material and end product

This industrial plastic granulator from Shuliy is mainly used for pelletizing rigid plastics such as plastic baskets, plastic drums, plastic pipes, plastic pallets, plastic cards, plastic containers, and so on. If your raw material is soft plastic such as plastic film, you can take a look at our other soft plastic granulator machine.

3 types of die heads for HDPE pelletizing machine

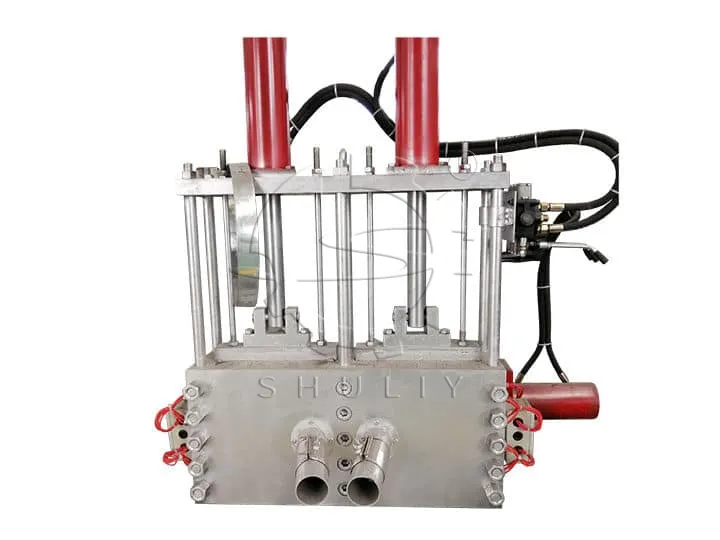

The three types of die heads of Shuliy plastic pelletizing machines are electric gear die heads, hydraulic die heads, and automatic slag filters. Each of these three types of die heads has its own unique advantages and characteristics, which can be selected according to different plastic materials and production requirements.

FAQ about plastic pelletizing machine

Q: What is the capacity of industrial plastic granulators?

A: The processing capacity of plastic granulators varies with models and specifications. Shuliy offers plastic granules extruder machines that cover a range of output from 200kg/h to 1000kg/h and can be customized according to your requirements.

Q: How can I ensure the quality and consistency of plastic pellets?

A. Through the use of high-precision die heads, especially motorized gear heads, precise control of the size and shape of the pellets can be achieved to ensure the quality and consistency of the pellets.

Q: What is the energy consumption of plastic pelletizing machines?

A: The energy consumption of a strand pelletizer machine depends on the model and specifications. Shuliy is committed to improving the energy efficiency of its equipment in order to reduce energy consumption.

Q: How long is the production cycle of plastic granules extruder machines?

A: The production cycle of HDPE pelletizing machines will vary according to the model and customized requirements. Generally speaking, the production cycle for standard models is 2-4 weeks, while the production cycle for customized models may be a little longer, subject to the notification after order confirmation.

Q: Is the density of plastic pellets adjustable?

A. Yes, the density of plastic pellets can be adjusted by controlling the process parameters and die design to meet the needs of different product manufacturing.

Video of Plastic pelletizing machine

Successful Cases

HDPE pelletizing machines are an effective solution for processing waste plastics. The emergence of plastic pelletizing machines effectively reduces the impact of plastic waste on the environment and promotes the development of the plastic recycling industry. With the help of Shuliy, plastic recycling projects have been set up in many countries such as Nigeria, Saudi Arabia, Malaysia, Ethiopia, and so on. And they are all profiting from it!

Strand pelletizer machine parameters

- Screw diameter: 125mm

- Main shaft speed: 50-70min

- Main motor: 22+1.5kw

- Capacity: 3t/day

- Screw diameter: 150mm

- Main shaft speed: 40-60min

- Main motor: 30+1.5kw

- Capacity: 5t/day

- Screw diameter: 180mm

- Main shaft speed: 40-50min

- Main motor: 45kw

- Capacity: 7t/day