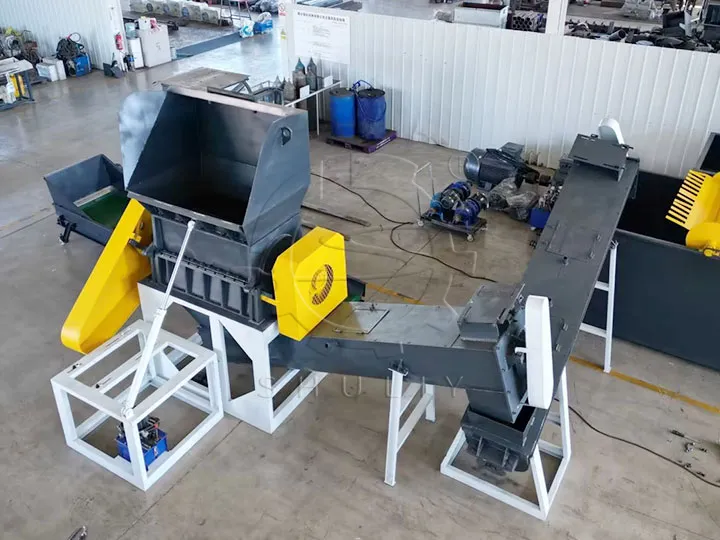

This hard plastic crusher is designed to handle rigid plastic materials and is suitable for pulverizing and regenerating many kinds of plastics such as PP, HDPE, ABS, PC, PVC, PA, and so on. The plastic shredder machine uses sharp blades to chip hard plastic materials such as bottles, containers, pipes, etc. into small pieces for subsequent reprocessing.

Introduction of Hard Plastic Crusher

Shuliy’s hard plastic shredder features blades made of high-strength alloy steel for high cutting efficiency and durability. The powerful motor drive ensures a stable and efficient pulverizing process, which can easily cope with even the hardest plastics.

The crusher plastic machine has many models to choose from, with outputs of 200kg/h, 500kg/h, 1000kg/h, and so on. If you need a larger or smaller output plastic shredder machine you can leave a message on the website and we can customize the machine for you.

The Raw Material Of Plastic Scrap Shredder

Our plastic scrap shredder is designed to handle a wide range of plastic materials, making it a versatile solution for various recycling needs. It can efficiently process materials such as plastic baskets, plastic pallets, HDPE containers, PVC pipes, plastic drums, and bulky plastic products.

Additionally, it is capable of shredding post-consumer and post-industrial plastic waste, including packaging materials, plastic films, and electronic waste housings. This flexibility ensures that our shredder can meet the demands of different industries, from waste management and recycling centers to manufacturing plants looking to repurpose plastic scrap.

Working Video of hard plastic Shredder

How Does A Hard Plastic Crusher Work?

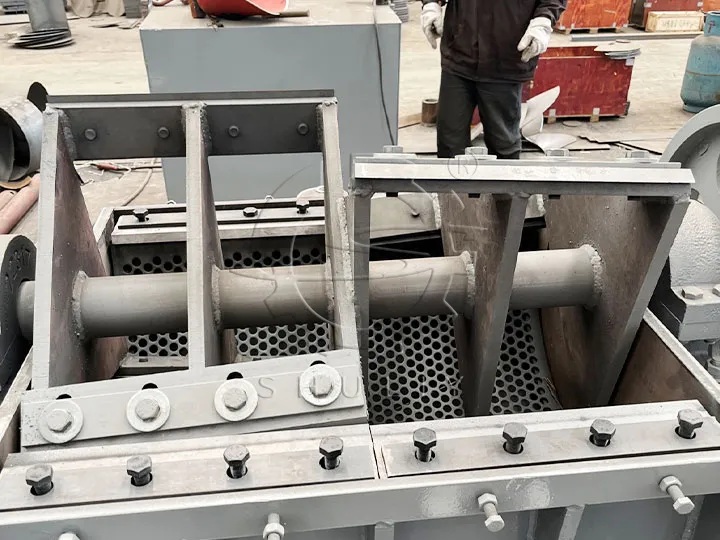

The main structure of the hard plastic crusher consists of a feed inlet, crushing chamber, blades, knife frame, screen, and discharge port. These components work together to make the HDPE shredder capable of efficiently processing hard plastic materials.

- Feeder: The material enters the plastic recycling shredder from here.

- Crushing Chamber: The crushing chamber is the space inside the hard plastic crusher, waste plastic is crushed here.

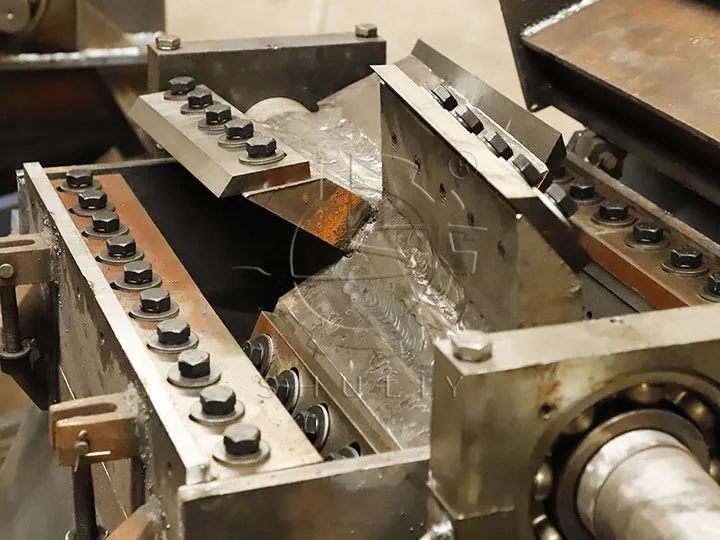

- Blades: The blades are the key components in the crushing chamber and are used to shred the hard plastic material into small pieces or granules. Our blades are made of 60Si2Mn or 5SiCr for excellent wear resistance and efficient cutting.

- Blade Frame: The blade frame is the structure that supports and fixes the blade, ensuring the stability and normal operation of the blade.

- Screen: The screen is located underneath the crushing chamber and is used to control the size of the particles produced. Qualified plastic fragments go to the next process, and unqualified oversized particles are crushed again. The hard plastic shredder is available in sizes ranging from 20 to 26 mm, which can be adjusted according to the customer’s actual needs.

- Outlet: The outlet is the exit of the plastic jug shredder, through which the crushed plastic granules are discharged.

Advantages Of Our Hard Plastic Crusher

High-quality blades: Our blades are made of 60Si2Mn or 5Sicr, which have excellent wear resistance and cutting power, and can work efficiently for a long time and reduce the frequency of blade replacement.

Adjustable screen aperture: The aperture of the screen can be adjusted according to the customer’s demand, and the rigid plastic crusher usually adopts the aperture of 20-26mm, which ensures that the crushed particles are uniform in size and suitable for subsequent processing or recycling.

Customized service: According to the different needs and production requirements of customers, we can customize the blades, screens, feed ports, machine shape, etc. of the pulverizer to ensure that the equipment is best suited to the customer’s production environment and objectives.

Selectable power options: Provides high-efficiency motor drive, suitable for most production environments, easy to operate, and energy-saving. For locations with no or unstable power supply, we offer a diesel engine drive option to ensure flexible use and efficient operation.

Difference between Soft and Hard Plastic Crusher

Types of Treatment Materials

Rigid plastic waste crusher: Specialized in handling hard plastic materials such as plastic drums, HDPE plastic bottles, ABS, PC, PVC, etc. These materials are usually thick and hard and difficult to pulverize, thus requiring higher cutting force and stronger blades.

Plastic film shredder: Suitable for processing softer plastic materials, such as plastic film, PP, PE bags, woven bags, and so on.

Crusher Screen

Hard plastic crusher: The sieve mesh has a small aperture, usually between 20-26mm.

Plastic bag shredder: The screen mesh has a larger aperture, usually between 40-55mm. The larger aperture is suitable for discharging soft materials and prevents clogging.

Discharge Method

Rigid plastic waste crusher: Hard materials are heavy do not require an additional discharge aid system, and can be smoothly discharged through the screen after pulverization.

Film shredder machine: Soft materials can be pulverized by adding water to the shredder or by installing a fan at the outlet. This is because soft materials are light and tend to wrap around the blades or clog in the screen. Adding water reduces friction and static electricity, while a blower can help the lighter material pass through the screen more easily and improve discharge efficiency.

Optional Equipment: Knife Sharpener

Our hard plastic crushers not only feature high-quality blades and flexible configurations but also offer customers the option to equip them with knife sharpeners. Customers can choose a knife sharpener for regular sharpening of the shredder blades according to their actual needs.

We recommend sharpening the blades once every 2-3 days, which not only prolongs the service life of the blades and ensures their cutting efficiency and precision, but also reduces the frequency and cost of blade replacement.

Hard Plastic Crusher Parameters

| Brand | Shuliy Machinery |

| Product | Hard plastic shredder |

| Output | 600-1200kg/h |

| Applicable materials | PP HDPE PVC PS ABS hard plastic |

| Blade material | 60Si2Mn |

| Screen size | Between 20-26mm |

| Power mode | Electric motors, diesel engines |

| Clearance between movable and fixed knives | Adjustable |

| Warranty | 1 year |

| Customizability | Can be customized |