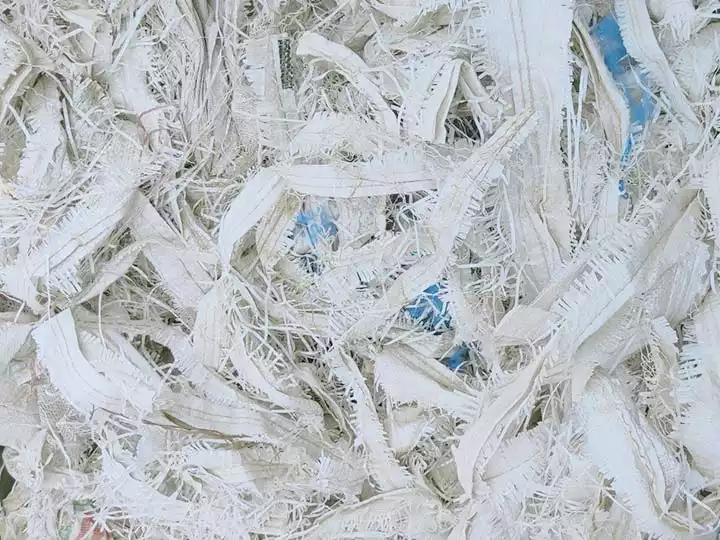

Our plastic film shredder is a highly efficient machine designed to handle all types of plastic films. The crusher machine can easily crush film materials such as LDPE, LLDPE, HDPE, BOPP, PP, etc. to reduce their size for subsequent washing and granulation.

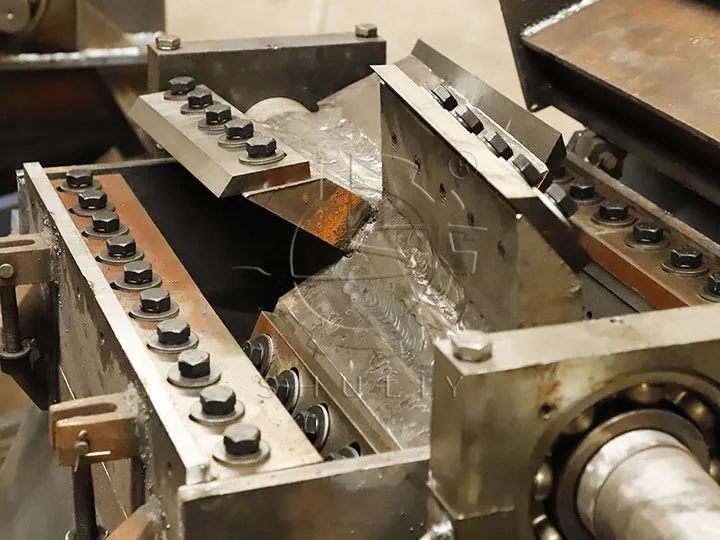

The machine adopts 60Si2Mn high-quality blades, which are wear-resistant and durable to ensure shredding efficiency and effect. Equipment configuration is flexible, according to customer demand to adjust the screen aperture and crushing capacity. Plastic shredding machines are suitable for all kinds of plastic recycling plants to improve the efficiency and output of film recycling and processing.

Advantages of Plastic Shredding Machine

Wide Application

The recycling crusher machine can be used not only alone but also with other equipment to form a production line. It can effectively pulverize films made of LDPE, LLDPE, HDPE, BOPP, PP, etc., and convert them into fragments, which are easy for subsequent processing and recycling.

Efficient Crushing

Our shredding plastic machines handle film materials with water to add weight, prevent clogging, and extend blade life for improved pulverizing efficiency and equipment durability.

Adjustable Design

The screen aperture size and blade gap of the equipment can be adjusted to meet the requirements of different materials and crushing to ensure the uniformity and quality of the discharged material.

Various Models

Our company provides a variety of models of recycling shredder machines, the output ranges from small to large and can be customized according to the specific needs of customers, to ensure that the equipment can be perfectly adapted to the customer’s production line, and improve production efficiency.

Materials That Can Be Handled

The plastic film shredder is suitable for film materials made of LDPE, LLDPE, HDPE, BOPP, CPP, OPP, PP, and many other materials. Including cement bags, agricultural film, nonwoven material, shrink wrap, stretch film, bubble wrap, laminated film, in-house film waste, plastic strapping, and so on. All can be efficiently pulverized into uniform pieces, ready for subsequent recycling and processing steps.

Advantages Of Wet Crushing Technology

Our plastic film shredders can add water to the machine when processing film materials. This not only increases the weight of the film and prevents clogging or tangling on the blades and rotor, but also reduces frictional heat and effectively extends the service life of the blades, improving shredding efficiency and equipment durability. This design not only enhances the performance of the machine but also extends its service life, providing customers with a more efficient and reliable solution.

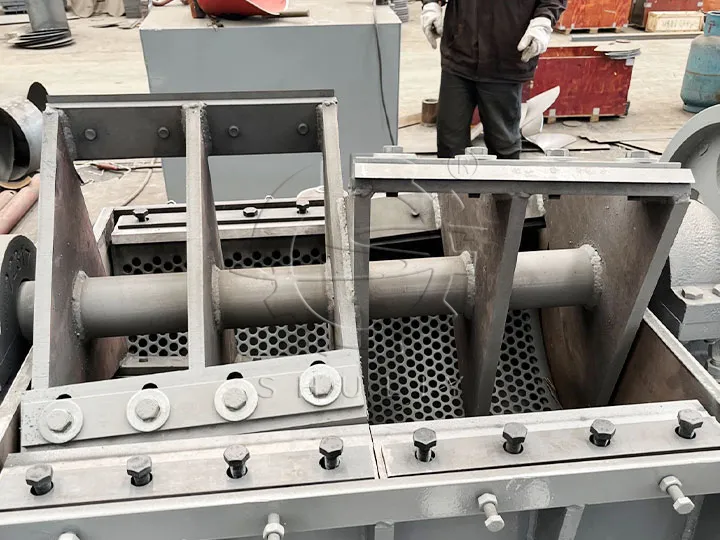

Working Principle

The plastic bag shredder is driven by the motor to rotate the movable knife disk at a high speed, and the movable knife and the fixed knife form a relative motion, utilizing the gap between them to crush and shear the large pieces of plastic. The crushed plastic is then filtered through a screen to output soft material of the required size.

Adjustable Options For Crusher Machines

- Screen aperture size: usually between 40-50mm, to adapt to the crushing needs of different materials.

- The gap between the movable knife and the fixed knife: it can be adjusted to meet the crushing requirements of different materials. Membrane materials need a smaller gap, while hard materials need a slightly larger gap.

- Screen and movable and fixed knife clearance: both can be adjusted to optimize the crushing effect.

- Fan configuration: A fan can be optionally installed at the discharge port to extract the crushed film more effectively.

- Power mode: according to customer needs and application scenarios, the equipment provides two power modes, motor and diesel engine, to ensure adaptation to different operating environments and production requirements.

Parameters of Plastic Film Shredder

The plastic film shredders, models SL-600, SL-800, and SL-1000, are equipped with powerful motors ranging from 30 kW to 55 kW, enabling them to efficiently process plastic materials. These plastic bag crusher machines exhibit varying capacities, with the SL-600 capable of handling 600-800 kg of material per hour, the SL-800 handling 800-1000 kg/h, and the SL-1000 accommodating 1000-1200 kg/h. All three models are equipped with 10 durable knives made of 60Si2Mn, ensuring effective shredding. Additionally, the Shuliy plastic bag shredder offers different box widths, measuring 600 cm, 800 cm, and 1000 cm respectively, providing versatility for various plastic processing needs.

Plastic Bag Shredder Precautions

- Regularly clean the plastic bag crusher machine, especially the blades and screens, to ensure crushing efficiency and quality.

- Make sure the power supply of the plastic film shredder is wired correctly to avoid electrical safety problems such as leakage and short circuits.

- When feeding, make sure the plastic film is clean to avoid foreign materials (such as metal, stone, etc.) entering the crusher plastic machine to prevent damage to the equipment.

- Before each use, check whether the various parts of the shredding machine are intact and make sure there are no loose, damaged, or abnormally worn parts.

Associated Recycling Equipment

Plastic film shredder is an important pre-processing equipment in plastic film recycling lines. It crushes the recycled plastic film into a size that can be easily pelletized. An industrial plastic shredding machine is usually used in conjunction with a range of recycling equipment such as plastic washing machines and plastic granulators to recycle plastic film.

Two Plastic Bag Shredders Exported To Ghana

Not long ago, we sent two industrial plastic shredder machines to Ghana. One was used to pulverize plastic film and the other to pulverize plastic baskets. These two industrial recycling crushing machines are generating revenue for our Ghanaian customers.

Inquiry

If interested in the plastic film shredder, please leave a message on the website. We will contact you within 24 hours.