As the demand for efficient plastic recycling continues to rise, the PET plastic bottle crusher has become a crucial piece of equipment for industries looking to process and repurpose waste PET bottles. This machine is specifically designed to handle the crushing of PET bottles, transforming them into smaller, manageable fragments that can be further processed in recycling lines.

Features of Bottle Crusher Machine

High Output Range

Equipment output ranges from 500-3000kg/h to meet the needs of small to medium sized recycling plants to large industrial applications.

High Quality Blade

The blades are made of 9CrSi high-quality material with high hardness and wear resistance, which can crush PET bottles stably and efficiently.

Adjustable Output Size

The standard screen aperture is 16-18mm, while the size can be adjusted according to the specific needs of the customer to ensure that the output meets the subsequent processing requirements.

Various Models

Our bottle shredder offers a wide range of models to choose from, the structural design and appearance of the color may vary depending on the model or technology update while supporting customized design to meet the special needs of different customers.

Flexible Configuration

The bottle shredder can be used alone or in conjunction with other recycling machines for plastic bottles to form a complete PET flakes washing line, dramatically increasing production efficiency.

What Bottles Can Be Processed In This Crusher?

PET bottle crusher is versatile and capable of handling a wide range of plastic bottles, including:

- Mineral Water Bottles: Lightweight and commonly used PET bottles for water packaging.

- Soft Drink Bottles: Carbonated beverage bottles with durable plastic structure.

- Juice Bottles: Transparent or colored PET bottles for fruit juices and beverages.

- Oil Bottles: PET bottles used for cooking oil.

- Detergent Bottles: Larger bottles for liquid detergents or cleaning agents.

- Milk Bottles: Rigid PET bottles used for storing dairy products.

- Pharmaceutical Bottles: Smaller bottles for medical liquids or syrups.

- Cosmetic Bottles: Plastic containers for shampoos, conditioners, and lotions.

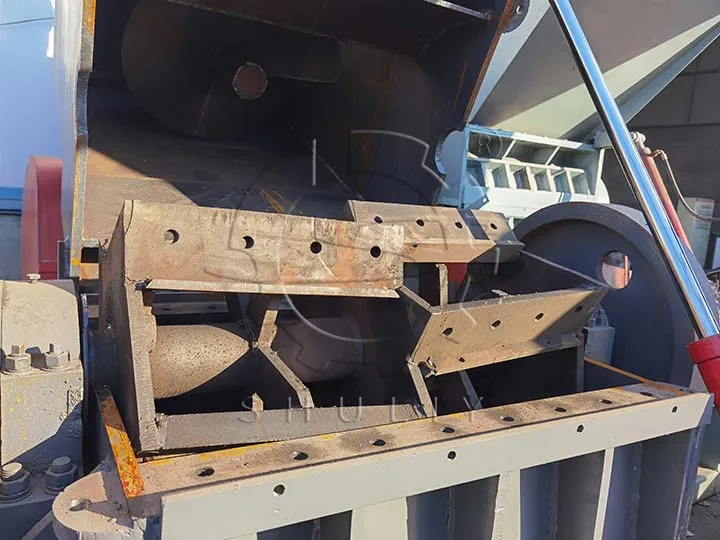

PET Bottle Shredder Structure

Plastic bottle shredder machine is mainly composed of a feed inlet, crushing chamber, screen, discharge inlet, motor, and reducer.

- Feeding inlet: The feeding system includes components such as a hopper and conveyor belt, which are used to put the plastic bottles to be crushed inside the bottle crusher.

- Crushing chamber: The crushing chamber is the core part of the bottle shredder, including the movable knife and fixed knife. The movable knife is usually fixed on the rotor, while the fixed knife is stationary in the casing, forming a certain gap between the two so that the plastic bottles can be effectively sheared and crushed.

- Driving system: Shuliy plastic bottle shredder machine usually consists of a motor, reducer, transmission shaft, etc., through the transmission device to drive the knife rotation, so as to realize the crushing of plastic bottles.

- Screen System: The screen is usually located inside the crushing chamber and is used to control the size of the crushed particles to ensure that they meet the required specifications. The screen size is generally 14-18mm.

- Discharge System: The discharge system is used to discharge the crushed plastic flakes from the crushing chamber. The discharged plastic flakes can go directly into the PET flakes washing machine for cleaning.

Applications

The PET plastic bottle crusher is ideal for:

- Recycling plants looking to process PET bottles for re-use.

- Beverage companies aiming to manage post-consumer bottle waste.

- Community recycling programs to handle large volumes of PET waste.

Plastic Bottle Crusher Parameters

Capacity: 200-500kg/h

Motor: 11 kW

Knife: 5 pcs

Dia. : 325mm

Capacity: 1200kg/h

Motor: 20-30 kW

Knife: 10 pcs

Dia. : 425mm

Capacity: 1500kg/h

Motor: 37 kW

Knife: 12 pcs

Dia. : 425mm

We will provide the right model according to your output and can design it according to your requirements. You can leave your message on our website for more information.

Plastic Bottle Crusher Operation Precautions

FAQ About Water Bottle Crushing Machine

Q1: Can the plastic bottle crusher handle different types of plastic bottles?

A1: Yes, the plastic bottle crusher is designed to process various types of plastic bottles, including PET, HDPE, and more.

Q2: What is the expected lifespan of the blades?

A2: Under normal use, it is recommended to change the set of blades in 3-4 months.

Q3: Is the PET bottle shredder suitable for industrial-scale operations?

A3: Yes, it is designed to handle high volumes of plastic bottle crushing, making it suitable for industrial applications.

Q4: How do I clean and maintain the screening system?

A4: Regularly inspect the screen for any blockages or wear, and clean it as needed to ensure proper functioning.

Q5: Can I adjust the size of the crushed particles?

A5: Yes, the screening system can be adjusted to achieve the desired particle size range.

Blade Installation And Maintenance

Water bottle crushing machine blades are an important part of crushing materials. After a period of time, the blades will become stale and affect the crushing effect. Therefore, it is necessary to replace the blades regularly to ensure the normal operation and working efficiency of the plastic bottle shredder machine. The following are the steps for installing the blades:

- Using a wrench and screwdriver, remove the old blades from the plastic bottle crusher. Be careful not to use too much force to avoid damaging the machine and yourself.

- After removing the old blade, you need to clean the inside of the PET bottle shredder where the base and blade are fixed. Use a brush to clean them to ensure that the blades can be installed properly.

- Install the new blade inside the plastic bottle crusher. Before installing the blade, it is recommended that the edges of the blade be lubricated to allow it to be placed easily in its support position. Then, screw on the screws and nuts to secure the blade to the base.

- When installing the bottle shredder blades, you need to make sure that each blade is in its correct position. If the blades are not installed correctly, the proper functioning of the PET crusher will be affected.

plastic Bottle Crusher in Bottle Recycling Line

The plastic bottle shredder machine is located after the plastic bottle label remover in the bottle recycling line. A conveyor belt is used to connect the water bottle crushing machine and the plastic bottle label remover, which can realize automatic feeding and improve production efficiency.