Plastic bottle label remover is a specialized equipment for removing labels from the surface of PET bottles. It effectively peels off the plastic or paper labels from the bottles through the high-speed rotating blade or friction effect, without damaging the bottle structure.

After the label removal, the PET bottles can go directly to the next step of the crushing and washing process, which improves the efficiency of the whole PET recycling process and the quality of the finished products. The equipment is suitable for PET bottles of various specifications, is easy to operate, and low maintenance cost, and is one of the key machines in a plastic bottle recycling plant.

Advantages of Label Removing Machine

Roles of Plastic bottle label remover

The main function of the PET bottle label-removing machine is to remove PVC labels from the surface of PET bottles. Through efficient mechanical de-labeling, it ensures that the purity of the bottle flakes meets the requirements during the subsequent PET bottle flake cleaning process, thus enhancing the quality of the recycled PET material. This process is essential to reduce the amount of impurities in the bottle flakes and increase the market value of the recycled product.

Raw material for PET label remover machine

PET bottle label removing machine is designed as a solution for PET bottles such as beverage bottles, mineral water bottles, plastic jugs, and so on. But it can also handle plastic bottles made of other materials, such as milk bottles made of HDPE, shampoo bottles, detergent bottles, plastic cans, and so on.

Video of PET Bottle Label Removing Machine

PET Label Remover Machine Working Principle

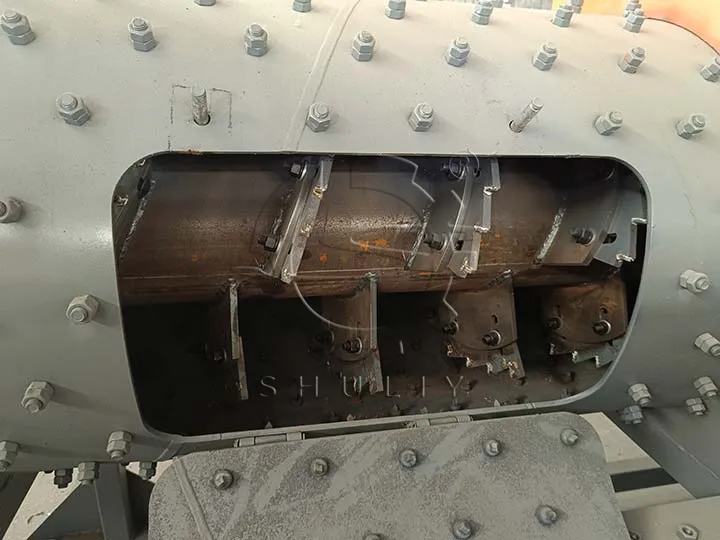

The PET plastic bottle material will be conveyed to the inlet of the label remover, the spindle rotates to drive the PET bottle forward. After the spindle rotation of the dynamic knife and the cylinder wall of the fixed fixed knife spiral friction, so that the label paper falls off. These special claw knives are made of copper welded to a fast-rotating spindle that pushes the bottle forward at a specific angle. Once the labels are cut, they are blown into a collection chute and then blown out.

The spacing between the spindle alloy blades and the inner wall blades can also be flexibly adjusted according to the different sizes of bottles. It is reasonable to avoid the scratch of the blade on the bottle body so that the output of the manufacturer’s bottle flakes is of better quality and sells at a higher price.

Label Removing Machine Specifications

| Capacity | 500kg/h-6000kg/h |

| Color | Customer’s request |

| Motor Power | According to the capacity |

| Blade Material | Tungsten carbide |

| De-labeling rate | 98% |

| Machine quality | Carbon steel |

| Applicable materials | PET or HDPE bottles |

| Barrel wall thickness | 100mm |

FAQ about PET label remover machine

What Types Of Bottles Is The Label Remover Machine Suitable For?

Plastic bottle label removers are usually suitable for PET bottles but can be adapted to handle other types of plastic bottles as required.

What Is The Off-Label Rate? What Is The Blade Material?

The de-labeling rate is up to 98%. The blade material is tungsten carbide.

How Does The Machine Handle PVC Labels?

The PET bottle label remover is equipped with a blower system that blows out the PVC labels and reduces the PVC content in the final product to 100-300mg/kg, ensuring the purity of PET bottle flakes.

Can The Machine Handle PET Bottles Of Different Sizes?

The plastic bottle label remover can be adjusted according to different sizes of bottles to adapt to different specifications of PET bottle processing needs.

How Often Is The Plastic Bottle Label Remover Maintained?

Maintenance of the plastic bottle label remover depends on the frequency of use and the working environment, but it is usually recommended to check the blades regularly for wear and to clean and lubricate them as necessary.