EPE pelletizer machine is a foam recycling machine used to process Expanded Polyethylene (EPE) foam material into pelletized form. It converts EPE foam into reusable pellet material through a series of process steps, including feeding, heating, extrusion, and molding.

What is EPE material?

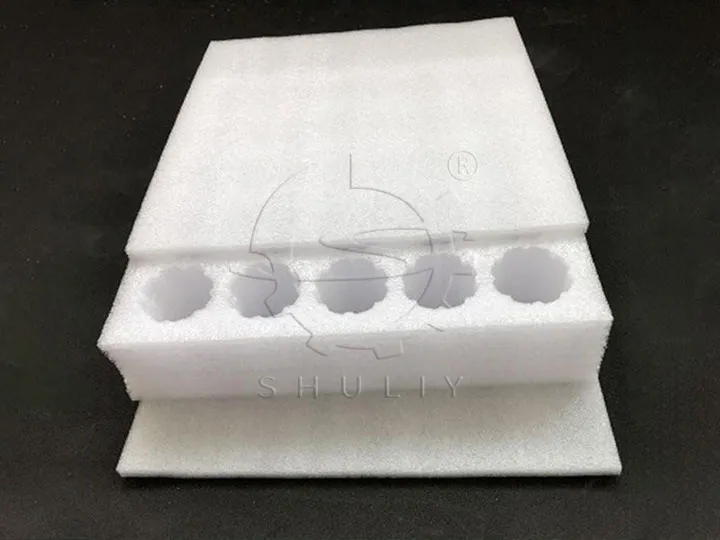

EPE, or Extended Polyethylene, is a lightweight, flexible foam material commonly used in packaging, cushioning, and insulation. It is known for its excellent shock-absorbing and moisture-resistant properties, making it a popular choice for a variety of applications. Common EPE pearl cotton, EPE foam sheets, and EPE packaging materials can all be used as raw materials for EPE foam granulators.

Structure of EPE pelletizer machine

The EPE foam granulator consists of a number of key components, each of which plays a vital role in the granulation process.

- Inlet: This is where the EPE foam material is fed into the expanded polyethylene granulation machine for processing.

- Gear Reducer: It helps regulate the speed of the EPE pelletizer machine, ensuring optimal performance during the pelletization process.

- Vent: This component allows for the release of excess gases generated during the pelletizing process.

- Heating Part: It facilitates the controlled heating of the EPE foam, preparing it for the pelletization process.

- Die Head: The die head is responsible for shaping the heated EPE foam into uniform pellets.

- Power Distribution Cabinet: This component manages the electrical aspects of the plastic foam pelletizing machine, ensuring safe and efficient operation.

Parameter of EPE foam granulator

Highlights of EPE pelletizer machine

How to choose right EPE pelletizer machine?

Choosing the right expanded polyethylene granulation machine depends on a variety of factors, including the amount of EPE foam to be processed, the size of pellets required, and budgetary considerations. Here are some key considerations:

| Capacity | Choose an EPE pelletizer machine with a capacity that matches your production needs. Different models of machines offer different capacity options, so evaluate your needs carefully. |

| Pellet size | Make sure the expanded polyethylene granulation machine’s die head can produce the range of pellet sizes you need. |

| Energy efficiency | Choose a plastic foam pelletizing machine with high energy efficiency to reduce operating costs. |

| Ease of Maintenance | Consider EPE pelletizer machines that are easy to service for routine maintenance. |

| After-sales service | Ensure that you get timely technical support, maintenance, and other services from the EPE foam granulator manufacturer after purchase. |