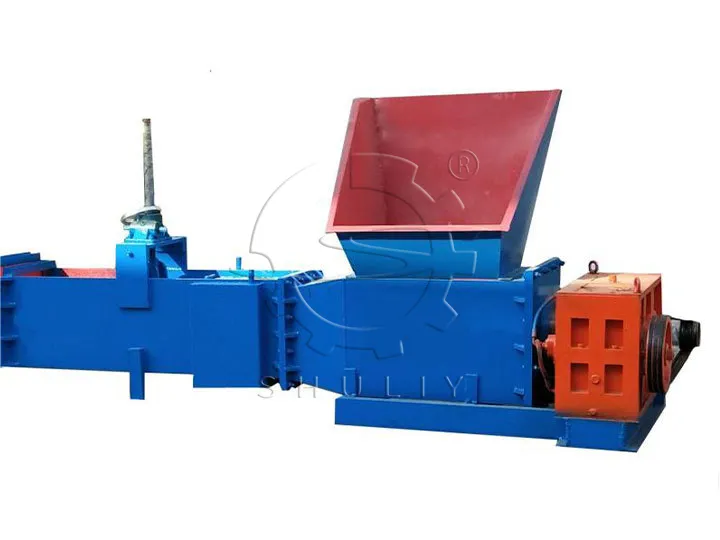

The styrofoam compactor is a specialized piece of equipment designed to process EPS (Polystyrene Foam) and is designed to effectively reduce the volume of the foam material. The equipment compresses EPS foam into tight blocks through high pressure for easy storage and transport.

Introduction of Styrofoam Compactor

The structure of an EPS compactor usually consists of an inlet, compression chamber, and outlet, which makes it easy to operate and suitable for recycling operations of all sizes. Its efficient compression capacity not only reduces transport costs but also improves recycling efficiency, making it an important and indispensable piece of equipment in the foam recycling industry. By using cold compactor machines, companies can effectively manage foam waste and reuse resources.

It is worth mentioning that the EPS styrofoam compactor does not require high-temperature treatment when compressing the foam, which is the main difference between it and the foam melting machine.

Advantages of EPS compactor

- High compression ratio: EPS foam can be effectively compressed into dense blocks or boards, with a high compression ratio of 40 times, greatly reducing the volume.

- No odor: Adopting the cold pressing method, no odor will be produced during the working process.

- Easy to maintain: EPS foam compactor structure is simple. Maintenance and upkeep are relatively easy, which can reduce the maintenance cost.

- Space saving: compressed blocks take up less storage space and are easier to manage.

- Reduced transport costs: Reduce overall transport costs by reducing the amount of space required during transport.

How Does The EPS Foam Compactor Work?

- First, the waste foam material is put into the inlet of the EPS styrofoam recycling compactor.

- The crushing device crushes the EPS foam into small pieces.

- The styrofoam compactor is activated. A mechanical device or hydraulic system starts to apply a uniform and continuous pressure to the foam.

- Under continuous pressure, the foam material is gradually compressed into denser blocks or slabs.

- The compressed foam blocks or boards can be removed from the discharge port of the foam compactor machine for subsequent storage, transportation, or reprocessing.

Working Video of EPS Compactor Machine

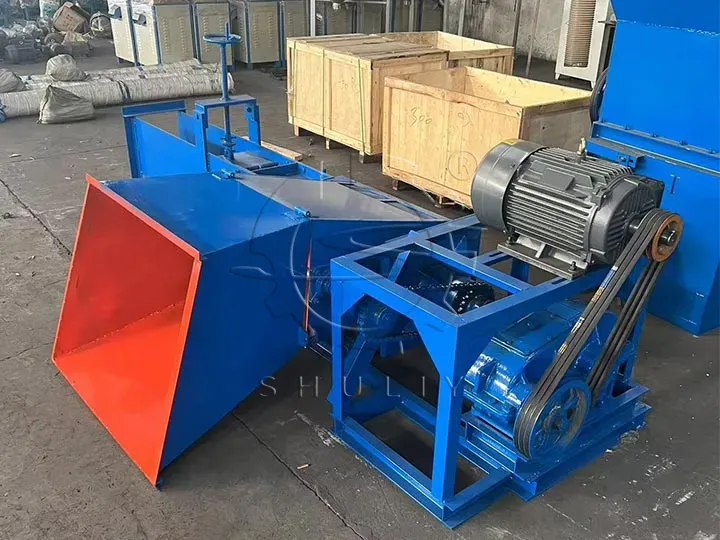

2 Types of Densifier Machines

We offer two types of densifier machines, vertical and horizontal. Vertical EPS styrofoam compactor adopts the top feeding method, which is easy to operate and suitable for occasions with small space; while horizontal foam compactor adopts side feeding method, with the inlet flush with the ground, which is convenient for quick material placement. These two designs have their advantages, and you can choose the right equipment according to your specific needs.

Vertical EPS styrofoam compactor

Parameters of Styrofoam Compactor

| Model | 260 | 300 | 350 | 400 |

| Power(kW) | 7.5 | 11 | 11 | 15 |

| Compression ratio | 40:01:00 | 40:01:00 | 40:01:00 | 40:01:00 |

| Input size(mm) | 600*800*1400 | 600*800*1400 | 800*900*1400 | 800*900*1600 |

| Output size(mm) | 260*260 | 280*280 | 350*350 | 400*400 |

| Capacity | 400-600 | 400-600 | 600-800 | 800-1000 |

| Weight | 600 | 700 | 800 | 1200 |

Successful Case

One of our customers from Malaysia was faced with the problem of disposing of a large amount of foam waste. These foam wastes took up a lot of space during transportation and storage, which caused great difficulties in recycling. After consultation and analysis by Shuliy’s professional team, we recommended our styrofoam compactor to our customers to solve this problem.

The client has significantly reduced the volume of foam after using the EPS foam compactor. This enabled them to store and transport the waste more efficiently, saving significant resources and costs.

For more details: EPS Styrofoam Compactor Sent To Malaysia