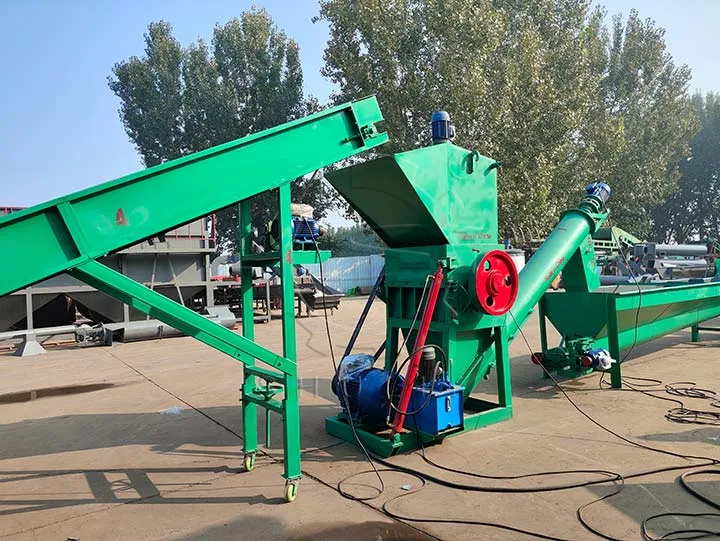

Crusher machine for plastic is a kind of mechanical equipment specialized in crushing and breaking waste plastics. Its main purpose is to break down larger volumes of plastic materials into smaller particles for subsequent reprocessing. Of course, if you use the plastic water bottle crusher improperly, it will affect the product quality and equipment life. The following will teach you how to properly use the plastic water bottle crusher.

The use of crusher machine for plastic

- Confirm that the plastic water bottle crusher is installed and stable: Before use, check whether the plastic water bottle crusher is firmly installed and ensure that all parts of the machine are in normal working condition.

- Add materials: Add the materials to be processed evenly into the crusher machine for plastic to avoid clogging or burning the crusher machine for plastic.

- Adjust processing parameters: Adjust processing parameters, such as speed, knife distance, and other parameters to meet the required product size.

- Start the plastic jug shredder: Start the power supply and set the required crushing time through the control panel.

- Clean the plastic jug shredder: After finishing the processing, the internal and external surfaces of the crusher machine for plastic and the operation area must be cleaned to keep the plastic water bottle crusher hygienic and safe for operation.

Precautions for plastic jug shredder

- Before use, the crusher machine for plastic must be carefully checked for damage or failure.

- Long-term use will lead to wear and tear of the plastic jug shredder parts, and the machine should be regularly maintained and serviced.

- When cleaning the equipment, please make sure to clean all the inside of the plastic water bottle crusher, so as to avoid residual material contamination of the next processing.

- In the process of processing, one must pay close attention to the volume of the material inside the crusher machine for plastic, to avoid material overload caused by equipment overflow.