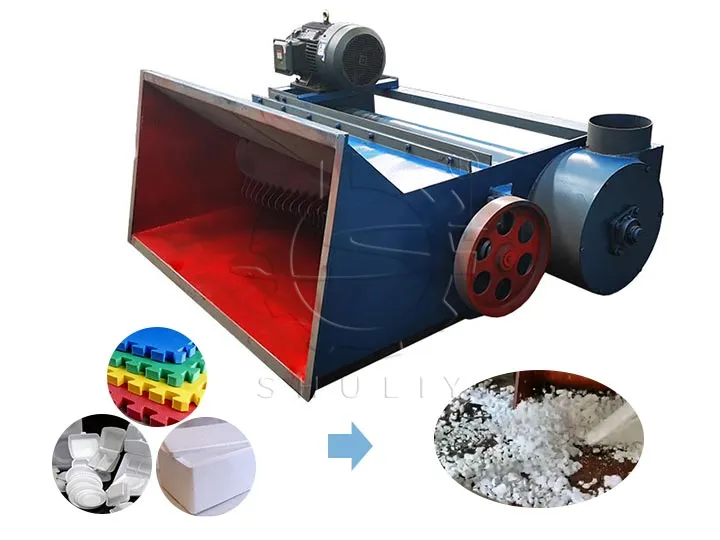

Foam crushing machine is mainly used to crush waste foam products such as foam boxes, foam boards, thermal insulation materials, foam filling materials, and other waste foam products into small pieces. Then the foam blocks are blown into the storage bin to provide a constant supply of raw materials for the foam granulator.

Foam crushing machine Application

Shuliy foam crusher machine adopts highly efficient crushing technology, which is able to process large quantities of foam scrap quickly and evenly. The following are some common waste foams:

Packaging and fast food boxes

Insulation boards and tubes

Thermal insulation in construction

Protective pads for electronic equipment

Cushioning packaging materials such as electronic packaging

Children’s toys or play mats

Flower packaging materials

Foam models

Car seats and seat cushions

Padding materials such as sofas and mattresses

Protective gear for sports equipment

Supports and protectors for the medical field

Working Principle of Foam Crushing Machine

The polystyrene shredding machine utilizes internal high-speed rotating blades or knife wheels to shear and crush the waste foam products, breaking them into small pieces. These small pieces of foam can be convenient for subsequent foam granulation or reuse. At the same time, the Shuliy styrofoam shredder is also equipped with a dust removal system, which can effectively filter out the dust generated and keep the working environment clean. The whole crushing process is efficient and fast, providing a reliable solution for the disposal of waste foam.

Features of Shuliy styrofoam shredder

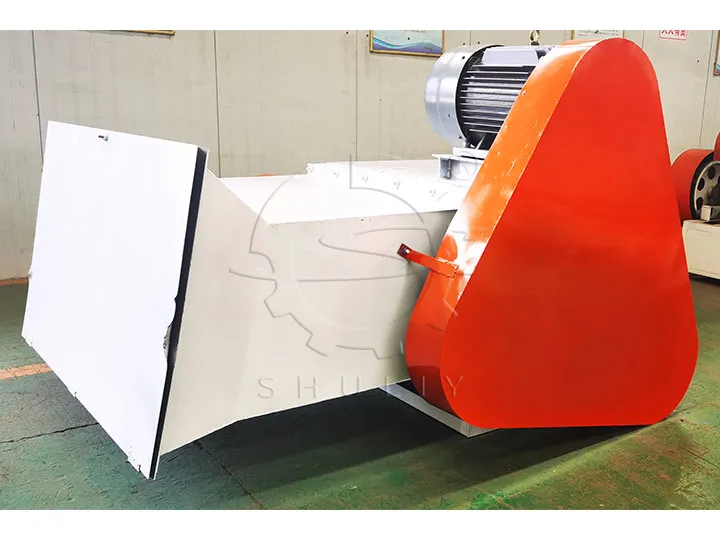

- Shuliy foam crushing machine adopts side feeding. The feeding opening is flush with the ground, which is convenient for feeding.

- The size of the crushed particles can be adjusted as needed.

- Suitable for different kinds of foam materials, such as EPS, EPE, etc.

- Foam crusher machines adopt an advanced manufacturing process to ensure the reliable quality and high durability of the foam shredding.

- According to the actual needs of customers, we can provide customized designs to meet the needs of different sizes and models of foam processing.

- We provide a full range of after-sales services, including installation, maintenance, etc., to ensure a smooth experience for customers in the process of foam crushing.

Foam Crushing Machine parameters

| Model | Feed port size | Power( kw ) | Capacity( kg/h ) |

| SL-800 | 800*600 | 5.5 | 250-300 |

| SL-1000 | 1000*600 | 5.5 | 300-350 |

| SL-1200 | 1200*600 | 7.5 | 400-450 |

| SL-1500 | 1500*800 | 11 | 450-500 |