Plastic granulation line needs to choose a suitable layout plan according to the factory area and production demand. This will better optimize the production process and improve the operational efficiency of the plastic recycling granulating line. Shuliy provides personalized designs, customized according to customer needs. Today, we would like to introduce a few plastic granulation solutions that our company has designed for our customers.

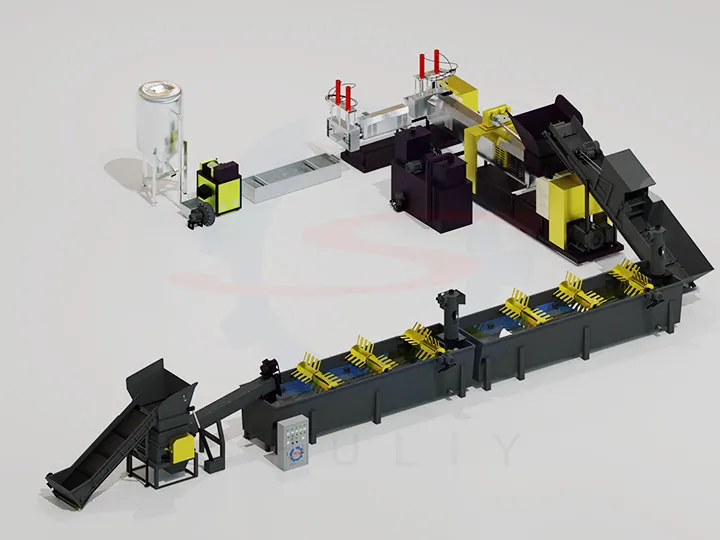

“U” shaped plastic granulation line

The U-shaped layout is suitable for larger plant areas and helps to maximize the use of space. This layout allows the plastic granulation line to form a “U” shape with open space in the middle. This layout is ideal for situations where large quantities of raw materials need to be transported and handled.

“L” shaped plastic flake pelletizing line

The L-shaped plastic flake pelletizing line layout is suitable for relatively narrow but long plant areas. This layout makes the plastic granulation line present an “L” shape. It is suitable for organizing the different production stages in an orderly manner and ensures a smooth production process.

“I” shaped plastic granulation line

An I-shaped layout is a linear layout. Each link of the whole plastic pelletizing line is arranged in sequence, and the process is intuitive and clear. It is suitable for plastic pelletizing plants with high requirements for process control and enough spacious space.

When making design choices, you need to take into account your specific production needs, plant size, and process flow. Each plastic recycling granulating line layout has its own applicable scenarios. If you are not sure how to choose, welcome to consult us. Our engineers will design the most suitable solution for you.