Our plastic pelletizing machine is a specialized equipment for recycling and processing PP, PE, ABS, PVC, and other rigid plastic wastes. It makes high-quality plastic granules by crushing, melting, extruding, and granulating the waste plastics. This equipment is suitable for the recycling of all kinds of rigid plastics and is widely used in the fields of plastic processing and recycling manufacturing.

Introduction of plastic pelletizing machine

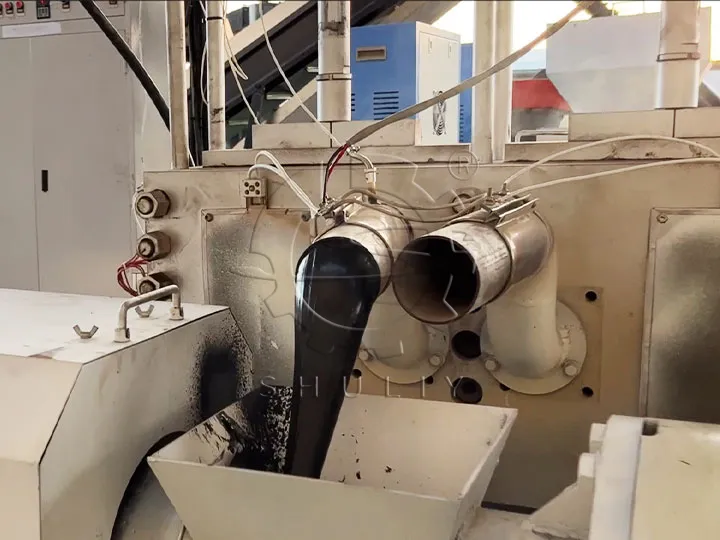

The strand pelletizer machine is the most important machine in the waste plastic recycling line. It converts waste plastic into recycled plastic pellets. Different models have different outputs. Shuliy can provide plastic granules extruder machines with outputs ranging from 200kg/h to 1000kg/h. Of course, if you need a larger capacity, we can customize it for you.

Advantages of Pelletizing Machine Plastic

- Multi-functional applicability: suitable for recycling and granulation of PP, PE, PVC, ABS, and many other plastic materials.

- High-quality pellet production: uniform and stable plastic pellets with good melting effect, suitable for high-quality processing of many kinds of recycled plastics.

- High material conversion rate: Advanced technology improves the conversion efficiency of waste plastics, reduces losses, and maximizes the rate of finished products.

- Customized design: Customize the equipment according to the customer’s raw materials and needs, and provide professional suggestions such as die head and heating method.

- Water ring pelletizing system: For materials with poor fluidity (such as plastic drums), a specially designed water ring pelletizing system can effectively improve the pelletizing efficiency.

Raw material and end product

This industrial plastic granulator from Shuliy is mainly used for pelletizing rigid plastics such as plastic baskets, plastic bottles, plastic flakes, plastic drums, plastic pipes, plastic pallets, plastic cards, plastic containers, and so on. If your raw material is soft plastic such as plastic film, you can take a look at our other soft plastic granulator machine.

Applicable Enterprise Types of Granulator

Plastic Recycling Business

Specialized recyclers collect post-consumer and post-industrial waste and process it into recycled plastic pellets for the production of new plastic products.

Plastic Products Manufacturers

These companies can utilize pelletizer machines to reprocess waste or trimmings from production into plastic granules, reducing waste and saving costs.

Suppliers of Recycled Plastic Pellets

Various plastic wastes are processed into high-quality recycled pellets through plastic waste extruder machines and supplied to other manufacturing companies to meet the market demand for recycled materials.

Working Video of Plastic pelletizing machine

The video below shows our Omani customer’s plastics recycling plant, processing PVC flakes.

Working Principle of Granulation machine

The pelletizer machine works by melting waste plastics by heating and extruding, then extruding them into continuous strips through a die head and cutting them into uniform plastic granules after cooling. This process usually includes several steps such as feeding, melting, extruding, cooling, and cutting, and is suitable for the recycling and reuse of all kinds of plastic materials.

3 types of die heads for HDPE pelletizing machine

The three types of die heads of Shuliy plastic pelletizing machines are electric gear die heads, hydraulic die heads, and automatic slag filters. Each of these three types of die heads has its unique advantages and characteristics, which can be selected according to different plastic materials and production requirements.

FAQ about plastic pelletizing machine

Q: What is the capacity of industrial plastic granulators?

A: The processing capacity of pelletizers varies with models and specifications. Shuliy offers plastic granules extruder machines that cover a range of output from 200kg/h to 1000kg/h and can be customized according to your requirements.

Q: Can soft and hard materials be pelletized at the same time?

A: Soft and hard materials can not be granulated at the same time, because the processing conditions of soft and hard materials are different, mixed granulation is likely to lead to cracks in the particles, affecting the quality of the finished product.

Q: What is the diameter of a long strip of plastic extruded by a pelletizer??

A: Approximately 3 mm in diameter.

Q: What is the delivery date of the plastic pelletizing machine?

A: 20-25days.

Q: What is the plastic granules machine price?

A. The price of a plastic recycling extruder machine varies depending on the type of machine, specifications, capacity, configuration, and supplier.

Strand pelletizer machine parameters

- Screw diameter: 125mm

- Main shaft speed: 50-70min

- Main motor: 22+1.5kw

- Capacity: 3t/day

- Screw diameter: 150mm

- Main shaft speed: 40-60min

- Main motor: 30+1.5kw

- Capacity: 5t/day

- Screw diameter: 180mm

- Main shaft speed: 40-50min

- Main motor: 45kw

- Capacity: 7t/day

In addition, our plastic pelletizing machines are available in a variety of models, each with different parameters and outputs to meet different needs.

Our equipment can be customized according to the customer’s raw material types, production requirements, and plant conditions, including the recommendation of suitable die heads, heating methods, and so on.

If you are interested in our granulator machine or need more detailed information, please contact us immediately, and we will provide you with professional consultation and quotation.