PET flakes washing machines, also called plastic float sink tanks, serve two main purposes. One is cleaning, removing dirt, grease, and other impurities from the surface of plastic bottle flakes so that the bottle flakes are restored to a clean state. The second is separation.

In the cleaning process, the sink float plastic separation will be based on the differences in the material of the bottle cap, using physical separation methods to separate the PP (polypropylene) material bottle caps from PET bottle flakes.

Features of Sink Float Plastic Separation

Versatile Separation Capability

The sink float separation tank is not only effective in separating PET bottle flakes from PP bottle caps but also plays a crucial role in PP and PE recycling by efficiently removing impurities from the materials.

Precise Polyolefin Content Control

The tank is designed to maintain strict control over polyolefin content, ensuring levels are reduced to ≤200-300 mg/kg, meeting high-quality recycling standards.

Improved Depth and Height

The upgraded PET flakes washing machine effectively prevents lightweight bottle flakes from sinking and being carried out when discharging the cap by increasing the depth and height, thus improving the separation effect and purity of bottle flakes.

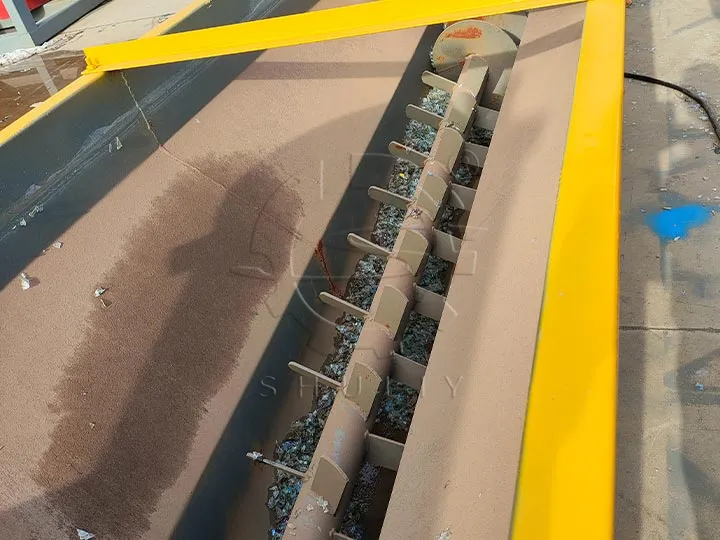

Equipped with Paddle Wheels

Certain models are equipped with paddle wheels, which effectively propel materials forward while simultaneously stirring and cleaning them. This feature enhances the tank’s efficiency and ensures thorough washing.

Importance of PET Flakes Washing Machine

PET bottle washing machine has a vital role in plastic bottle recycling lines, its importance is mainly reflected in the following aspects:

1. Cleaning Stains on PET Bottle Flakes

Waste PET bottle flakes have various dirt, grease, dust, and other impurities attached to the surface. These pollutants will affect the quality of PET bottle flakes reuse. PET flake washing machines can efficiently remove these pollutants and ensure the cleanliness of bottle flakes through soaking, rinsing, mechanical friction, and other methods.

2. Separating PET Bottle Flakes From PP Caps

Due to the different densities of PET bottle flakes and PP bottle caps (PET sinks to the bottom of the water and PP floats to the surface), the sink float separation tanks can take advantage of this property to completely separate the two materials. This not only improves the purity of the recovered material but also contributes to the smoothness of subsequent processing.

3. Increase recycling efficiency:

The clean and tidy PET bottle flakes can be used to re-produce new PET products such as bottles, fibers and so on. Through the processing of PET flakes washing machine, the reuse efficiency of waste PET bottles can be maximized, reducing the need for virgin material.

Working Principle of Plastic Float Sink Tank

The PET flakes washing machine separates the bottle caps made of PP through flotation separation. The density of PP bottle caps is smaller than water, while the density of PET bottle flakes is larger than water.

In the plastic float sink tank, when the broken plastic bottles enter the water, the PP bottle caps will float on the surface of the water because their density is less than water, while the PET bottle flakes will sink to the bottom of the water because their density is greater than water. This is the simplest and most effective way of separation.

The bottom of the plastic float sink tank is equipped with a spiral device, which pushes the PET bottle flakes that sink to the floor into the next washing process.

Number of Sink Float Plastic Separation

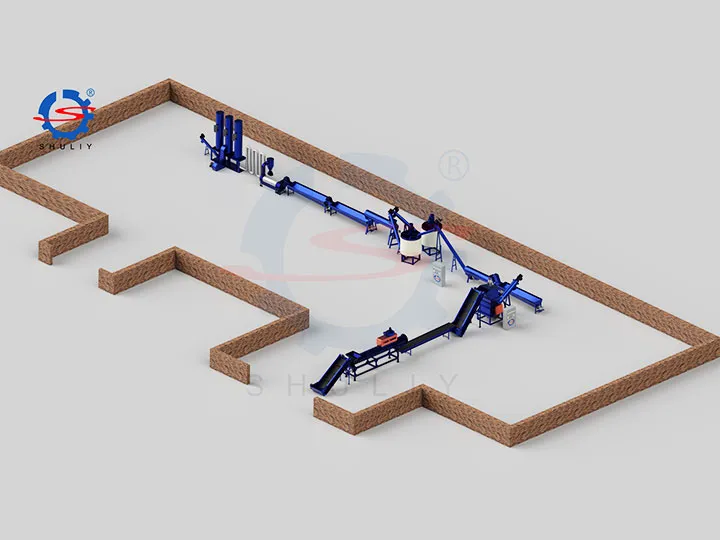

The number of sink float separation tanks in a PET bottle recycling line can be adjusted based on production capacity and the level of contamination in the materials.

For a 500kg/h PET washing plant, two separation tanks are typically configured. The first tank, placed after the PET bottle crusher, serves to separate PET flakes from bottle caps. The second tank, positioned after the hot washing tank, functions primarily for rinsing. It helps further clean off contaminants and washing agents carried over from the hot wash, ensuring the pH value remains within the required range.

For recycling lines with a capacity of 1000kg/h, it is recommended to configure two PET flakes washing machines after the hot washing machine. This setup ensures optimal cleaning and separation efficiency, particularly for high-capacity operations.

Parameters of PET flakes washing machine

- Length: 6.0m

- Width: 1.2m

- Height: 1.2m

- Motor power: 3kw, three-phase 380V50Hz

- Outer wall thickness: 4mm

- Blade thickness: 6mm