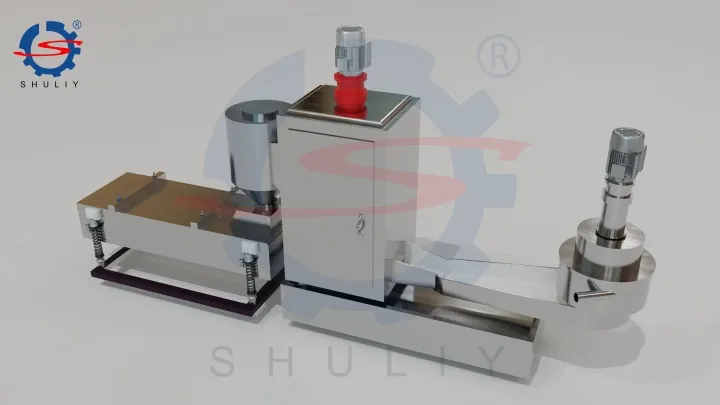

Plastic dana cutter machine, also known as the plastic pellet cutting machine, is a plastic cutting machine used to cut plastic strips extruded from plastic pelletizing machines into uniformly sized plastic pellets. Shuliy is a professional plastic dana cutter machine manufacturer. Our plastic machines have been exported to several countries and have already generated substantial profits for them.

Introduction of Plastic Pellet Cutter Machine

The plastic granule cutting machine is an indispensable and important equipment in the process of plastic recycling and granulation, which is mainly used to cut the extruded strip of plastic in the molten state into uniform granules and is widely used in the granulation processing of PP, PE, PET, PS, ABS, PA and other kinds of plastic materials.

Features of Dana Cutting Machine

- Cutting granule size about 3mm, adjustable;

- Adopting hard alloy hob, long blade life, replaced once per 2000 tonnes of pellets cut;

- Can be equipped with vibrating screen to ensure uniform and high quality granules;

- Provide water ring-cutting devices to meet diversified needs.

How does plastic dana cutter machine work?

- Firstly, the extruded plastic strip is fed into the inside of the plastic dana cutter machine through the inlet.

- After entering the plastic strip cutter, the material will be suppressed by the upper and lower pressure rollers to keep it in a stable condition, ready for cutting.

- Under the action of the pressing, the rotary cutter will begin to rotate rapidly. The sharp edge of the rotary cutter will cut the material into the required uniform particles.

- The cut plastic dana cutter machines will be discharged from the machine’s discharge port.

- If a vibrating screen is fitted at the back, it prevents the particles from sticking and removes shaped particles.

plastic Granule Cutter Application Video

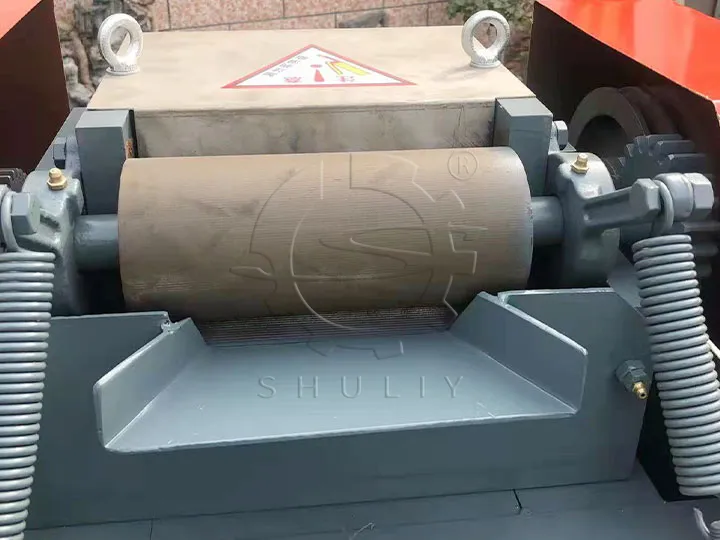

Blade of plastic dana cutter machine

The knife of the plastic dana cutter machine utilizes a roller knife design, which means that it uses rotating rollers to perform the cutting job. This design is often effective in cutting plastic pellets or strips into the desired uniform size of plastic granules.

Also, the roller knife design can be customized to meet specific cutting needs. To ensure cutting efficiency and accuracy, as a plastic granule cutting machine manufacturer, we recommend changing the knives once the plastic pellets cut by the plastic pellet cutter reach 2,000 tons.

Parameters of plastic strip cutter

- Rotate blade number: 18 tooth

- Power: 2.2KW

- Capacity: 150kg

- Dimension: 800*560*1150

- Rotate blade number: 22 tooth

- Power: 3.0KW

- Capacity: 250kg

- Dimension: 800*560*1150

- Rotate blade number: 22 tooth

- Power: 3.0KW

- Capacity: 280kg

- Dimension: 800*56081150

Areas of Application

Plastic pellet cutting machine is suitable for the following fields:

- Plastic Recycling Factory: for granulation and regeneration of waste plastics.

- Plastic products factory: to produce raw material pellets for injection molding, blow molding, extrusion, etc.

After-Sales Service

We offer full after-sales support including:

- Installation and commissioning: professional technical team to assist customers to complete equipment installation and commissioning.

- Training service: Provide detailed training for operators on the use and maintenance.

- Accessories supply: Long-term supply of high-quality blades and other accessories.

- Technical support: 24-hours online service, solves customer problems at any time.