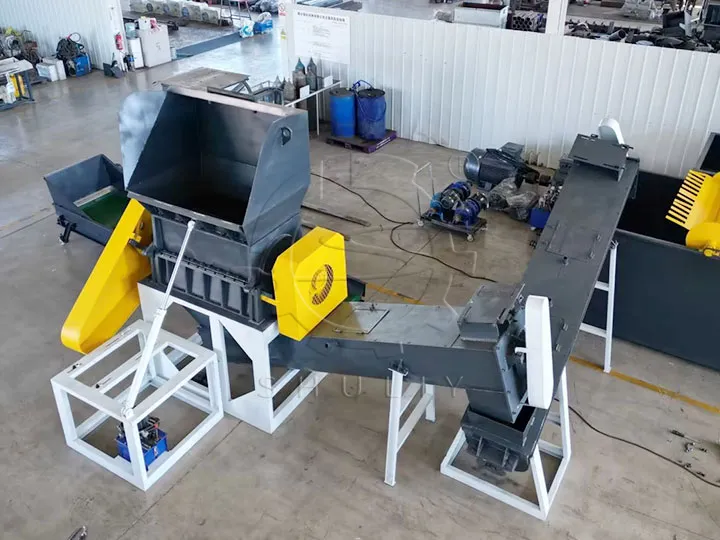

Waste plastic crusher is an indispensable piece of equipment in plastic recycling. It has a very important role in plastic crushing. The working efficiency of the plastic barrel shredder directly affects the whole recycling process. So do you know how to provide crusher efficiency?

Optimization of Waste plastic crusher knives

Choosing the right type of knife

Choosing knives that are adapted to the characteristics of the material being processed is the key to improving the efficiency of a plastic chipper shredder. Knives made of different materials are suitable for different types of plastics. For example, when dealing with hard plastics, high-strength, wear-resistant knives can be used; for soft plastics, the sharpness of the knives should be considered.

Regular inspection and maintenance

Regularly check the wear and tear of the crusher knives and replace the badly worn blades in time to ensure their efficiency. At the same time, keeping the sharpness and cleanliness of the crusher knives is also key.

Control of feed rate

Too fast or too slow feeding speed will affect the working efficiency of the plastic barrel shredder. Discharging too much or too little material at one time is also not conducive to the operation of the waste plastic crusher. Within the appropriate range, choose the feeding speed that adapts to the material characteristics to ensure that the plastic chipper shredder can run stably and efficiently.