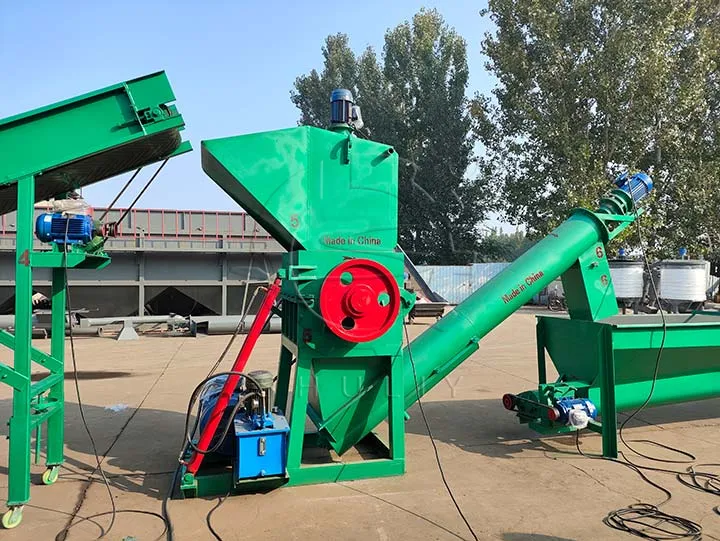

Film shredder machine in the use of the process sometimes does not feed the situation. Why is this? Today the PET crush bottle machine manufacturer analyzes it for you.

Film shredder machine Screen Problem

The automatic PET bottle crushing machine screen opening is too small, plastic feeding speed is too fast may lead to screen bottom clogging. The solution is to replace the PET crush bottle machine screen with a larger opening at the right time to improve the permeability.

PET crush bottle machine blade gap problem

Excessive film shredder machine blade clearance may result in material not being discharged smoothly. At this time we need to adjust the blade crushing gap to ensure that the material is repeatedly crushed.

Less material in film shredder machine

A film shredder machine will not completely run out of material because the material is driven upwards in the chamber by the airflow. The solution is to continuously add material to the automatic PET bottle crushing machine to ensure a stable production process.

Material handling issues

A PET crush bottle machine is usually equipped with a discharge conveyor. Customers should adjust the discharging conveyor according to the actual material in the production to avoid too slow discharging speed leading to screen clogging.