Pellet granulators commonly suffer from rapid wear and corrosion of screws and barrels during the extrusion and melting process. They usually need to be replaced after a period of use. In recent years, the industry has made significant progress in the in-depth study of screw wear.

Criticality of material selection

The material of the industrial pelletizer machine screw directly affects its wear resistance. Material selection takes into account factors such as the type of plastic being processed, temperature, and pressure to ensure that they continue to perform well in complex operating environments.

Advanced Surface Treatment Techniques

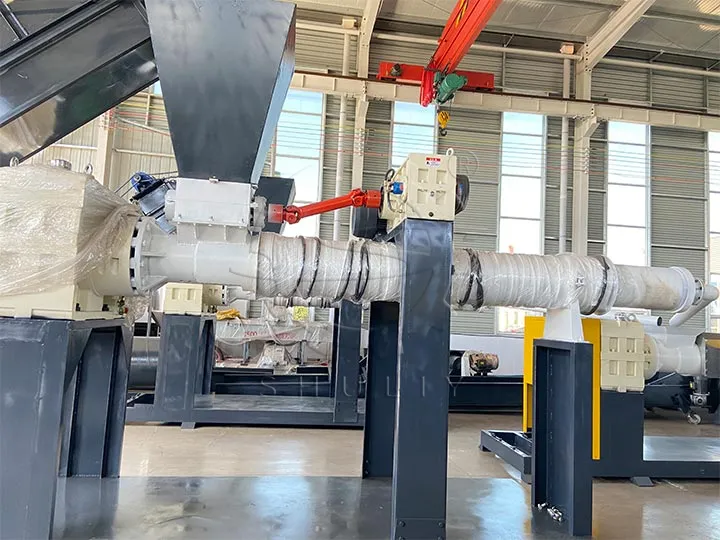

Surface treatment is essential to improve the wear resistance of pellet granulator screws. The top surface of the screw rib and the spiral surface of the screw can adopt the new technology of spraying and surfacing wear-resistant and corrosion-resistant alloys. These techniques can effectively slow down the wear process and extend the life of the pellet granulator.

Precision Manufacturing Processes

The use of high-precision mechanical manufacturing processes can ensure the surface flatness and precision of plastic extruder pellets machine screws and reduce friction and wear. The use of advanced CNC machining equipment, grinding technology, and quality control systems helps to produce more wear-resistant pellet granulator components.