Waste tire block cutter is a key machine used after the tire strip cutter in a semi-automatic tire recycling line. It cuts the rubber strips into small blocks (typically 3×5×6 cm or 5×5 cm), which are easier to feed into the rubber cracker mill for further processing into rubber granules or rubber powder. This step improves the feeding efficiency, reduces roller wear, and ensures smooth operation of the downstream grinding process.

Application of Tire Block Cutting Machine

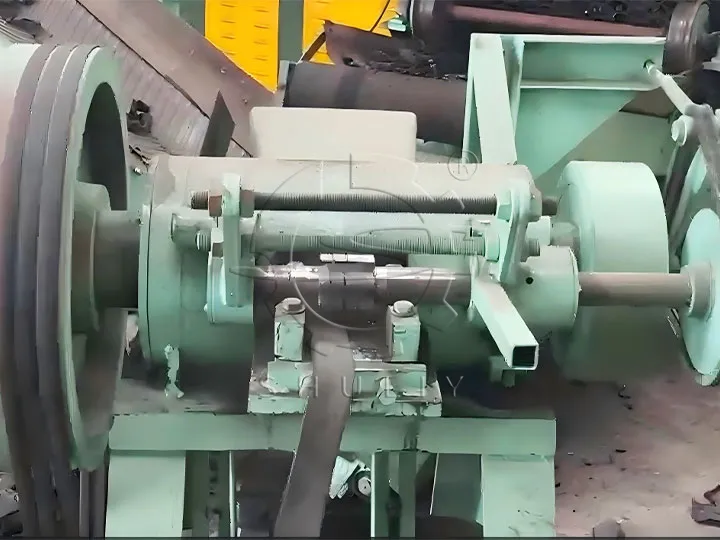

The tire block cutter is used to process the rubber strips cut by the tire strip cutter and cut them into uniform small blocks. It consists of a frame, motor, transmission mechanism, balancing device, two moving knives, a fixed knife, and a compression gear. The knives are made of high-strength alloy steel, which is wear-resistant and can be re-sharpened for repeated use.

Features & Advantages of Waste Tire Block Cutter

- Uniform Cutting Size: Produces consistent rubber blocks for efficient feeding into the grinder.

- Durable Alloy Knives: Long service life, can be re-sharpened multiple times.

- High Output: Capacity up to 1500 kg/h, suitable for medium and large tire recycling plants.

- Low Energy Consumption: Stable cutting speed and strong shearing force with minimal power usage.

- Easy Operation & Safety: Simple structure, safe and reliable operation.

Tire Block Cutter Technical Parameters

- Motor Power: 5.5 kW

- Capacity: 800 kg/h

- Cutting Block Size: 3×5×6 cm

- Dimensions (L×W×H): 1.0×0.8×1.4 m

- Weight: 800 kg

- Motor Power: 18.5 kW

- Capacity: 1500 kg/h

- Cutting Block Size: 5×5 cm

- Dimensions (L×W×H): 1.3×1.1×1.5 m

- Weight: 1200 kg

Waste Tire Block Cutter working Video

Contact Us for Tire Recycling Solutions

We can provide individual machines such as tire block cutters according to your specific needs, or design a complete tire recycling line for you. Our solutions cover bead cutting, strip cutting, block cutting, and grinding processes, helping you efficiently recycle waste tires.