The working principle of plastic recycled granules machine is relatively simple, but its importance to the plastics industry cannot be ignored. The use of wholesale plastic recycling pellet machines greatly improves the utilization rate of plastic, for the cause of environmental protection to make practical contributions.

Plastic recycled granules machine material feed

Plastic recycled granules machine material feeding methods have a variety of common manual feeding and automatic feeding in two ways. Manual feeding is suitable for small waste plastic recycling granules making machines, usually only need to manually pour the crushed plastic into the hopper.

The large-scale plastic granulation production line usually adopts an automatic feeding system. Through the conveyor belt and other equipment, pre-treated waste plastic is automatically transported to the wholesale plastic recycling pellet machine feeding port.

Preprocessing

After the material is fed, it needs to go through the pre-treatment process, including crushing, cleaning, drying, etc. Plastic will stick a lot of dirt during the collection process, and it is difficult to clean the large pieces of plastic. It is necessary to crush the plastic first before cleaning. Plastic with too much moisture will affect the quality of granulation and must be dried.

melt

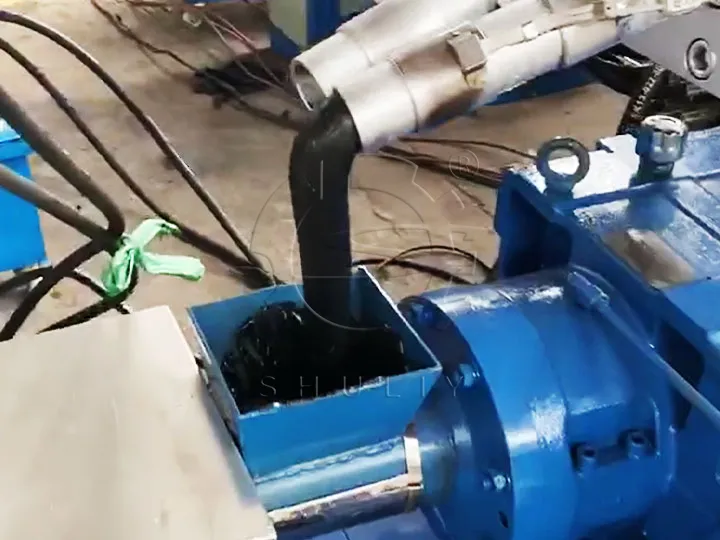

The plastic, which has passed through the pre-treatment, is conveyed to the heating zone of the plastic recycled granules machine. In the heating zone, the plastic is heated above the melting point and melts into a closed plastic flow state. After the plastic has been melted into a flow state, it needs to be pressurized by a rotating screw to the pressure zone of the waste plastic recycling granules making machine.

Extrusion molding

In the pressure zone of the plastic recycled granules machine, the melted plastic is compressed into a certain shape by the heating, pressure, and shearing action of the screw and barrel. At the same time, plastic pellets of different shapes and sizes can be molded by adjusting parameters such as the speed of the wholesale plastic recycling pellet machine and the temperature and pressure of the plastic after it is pressed through the mold.