Recently, our custom-made EPE foam granulator for a Mexican customer has been completed and will be shipped soon. This machine will be used to process a large amount of EPE foam materials collected by the customer, including foam boards, protective materials, and so on. The machine is designed with the customer’s needs in mind, with high efficiency and stability, and can meet the customer’s requirements for foam recycling and processing.

Features of This EPE Foam Granulator

Efficient Processing Capability

With a capacity of 250kg/h, this EPE pelletizer can efficiently process EPE foam materials provided by customers. Whether it is foam board or other protective materials, the machine can quickly crush and granulate them, saving time and labor costs for customers.

Heating Coil Heating Design

The equipment adopts the heating ring heating method to ensure that the material can be evenly heated during the pelletizing process, which improves the pelletizing efficiency and quality. This design not only saves energy and protects the environment, but also effectively avoids quality problems caused by uneven temperature of the material.

Customer Needs And Customized Services

Targeted Designs

The customer’s main requirement was to process large quantities of EPE foam materials, including foam boards and protective materials. We customized the EPE foam granulator according to the material characteristics and processing capacity provided by the customer to ensure that it could meet the customer’s actual production needs.

Strict Quality Control

During the production process, we manufacture the pelletizing machine in strict accordance with the requirements of customers and carry out many tests before leaving the factory to ensure stable operation and reliable performance of the equipment.

Delivery And Follow-up Support

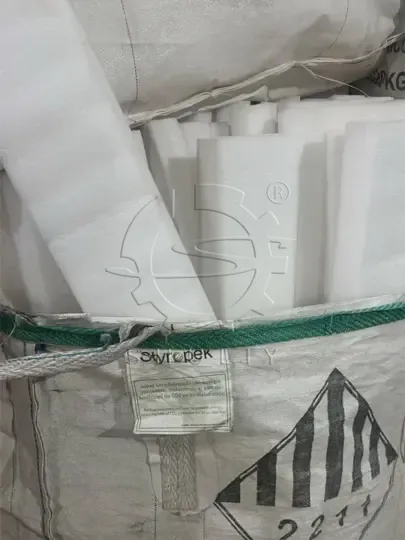

Packing and Shipping

At present, the EPE foam granulator has completed the final inspection and packaging and is about to be shipped to Mexico. We use professional packaging to ensure that the equipment is not damaged during transport and can arrive safely at the customer’s factory.

After-Sales Service

We provide our customers with comprehensive after-sales service support, including equipment installation guidance, operation training, and follow-up maintenance services, to ensure that our customers can use the equipment smoothly and maximize its benefits.