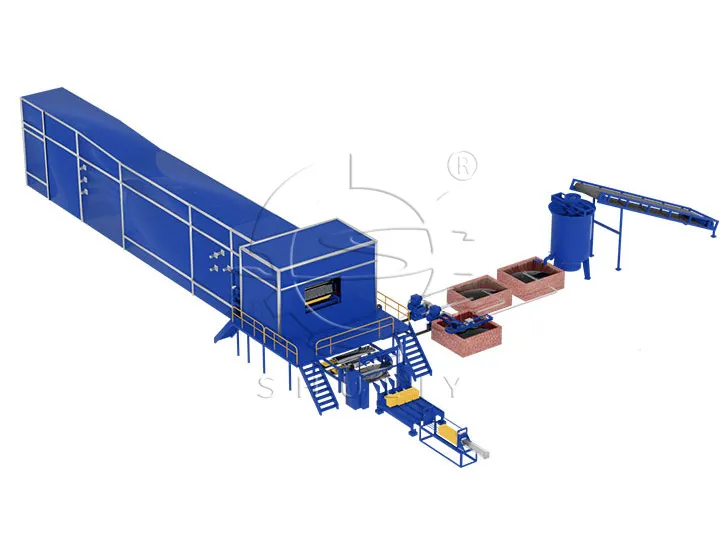

If you are looking for an efficient, stable, and easy-to-operate egg tray manufacturing plant, we offer a comprehensive one-stop solution that covers pulping, forming, drying, stacking, and packing. Our egg tray production lines are available in a full range of models, with capacities ranging from 1,000 to 8,000 trays per hour, making them suitable for small farms, medium-sized processing plants, and large-scale industrial orders.

The entire line features a compact structure, smooth operation, and supports custom molds for producing egg trays, fruit trays, coffee cup holders, and other molded pulp products. In addition to the equipment itself, we also provide process design, layout planning, installation and commissioning, operator training, and after-sales support to help customers start production quickly and run steadily.

What Is an Egg Tray Production Line?

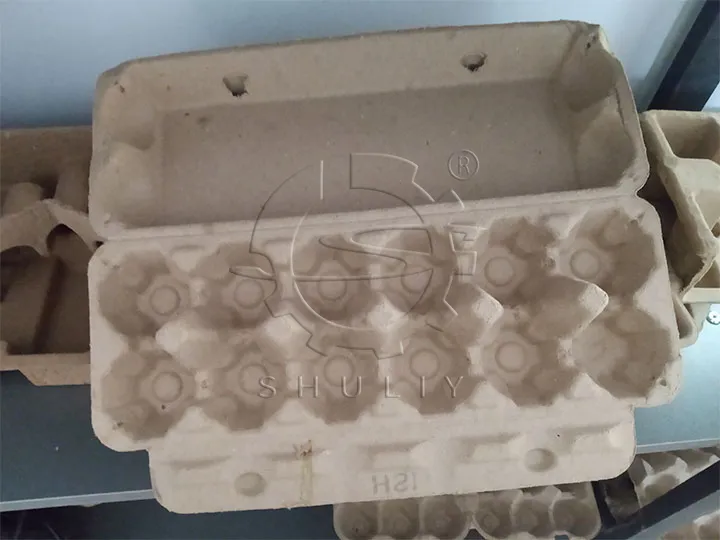

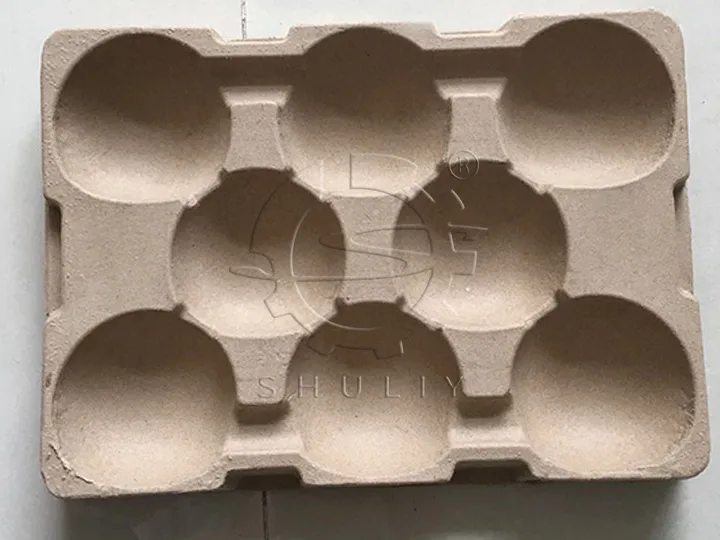

An egg tray manufacturing plant is a complete system designed to manufacture molded pulp trays from waste paper. The most common product is the 30-cell egg tray, but the line can also produce various types of pulp trays with mold changes, such as fruit trays, coffee cup holders, and industrial packaging trays.

The production line typically includes the following sections:

- Pulping system

- Forming system

- Drying system

- Stacking and packing system

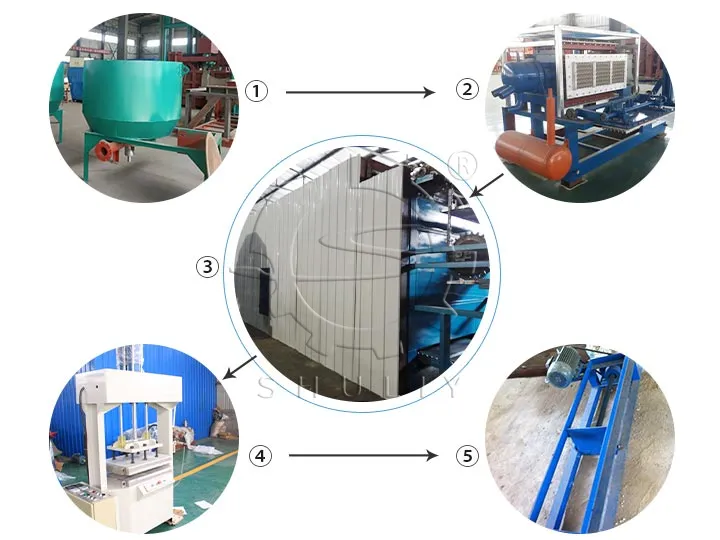

Egg Tray Production Process

1, Pulping

The process begins with recycling waste paper such as old newspapers, cartons, or book paper. These materials are mixed with water and processed in a hydraulic pulper, breaking them down into uniform pulp. The pulp is then adjusted for consistency and stored in a pulp pool, ready for use.

2, Forming

The pulp is pumped into the egg tray moulding machine, where a vacuum system draws the pulp onto a mold surface. This process shapes the wet pulp into egg trays. Once formed, the trays are transferred from the mold to the conveyor or the next system for drying.

3, Drying

Drying is essential for removing moisture and strengthening the trays. Depending on the customer’s needs and budget, the drying section can be designed as:

- Natural sun drying (suitable for small-scale production)

- Brick drying room (fuel or gas heated)

- Metal drying line (fully automatic, efficient, space-saving)

We will recommend the most suitable drying method according to the customer’s budget, climate and plant conditions.

4, Stacking and Packing

After drying, the trays are automatically stacked and can be packed manually or with an optional automatic packing system, ready for storage or transport.

Egg Tray Manufacturing Plant Configuration and Customization

We offer flexible configurations to meet different production capacities and space layouts. The egg tray forming machine can be single-sided or rotary (multi-sided), with output ranging from 1,000 to 8,000 trays per hour.

All molds can be customized to produce various pulp trays beyond egg trays, including:

- Egg cartons

- Apple and fruit trays

- Coffee cup holders

- Shoe inserts

- Industrial cushioning trays

- Seeding trays

The entire egg tray manufacturing plant can be tailored to customer requirements, whether for manual operation or fully automatic production.

What Production Capacity Do I Need For The Egg Tray Line?

The output of an egg tray manufacturing plant typically ranges from 1,000 to 8,000 pieces per hour, mainly depending on the structure of the forming machine (such as 1×4, 4×4, 4×8, etc.).

- For small farms or trial production, models with a capacity of 1,000–2,000 pieces per hour are suitable.

- Medium-sized processing plants are better suited to equipment producing 2,500–4,500 pieces per hour.

- For continuous supply or large orders, a high-capacity production line with over 5,000 pieces per hour is recommended.

If you’re unsure which production capacity to choose, please don’t hesitate to contact us. We usually recommend a suitable capacity range based on your available space, labor resources, and sales scale.

Advantages of Our Egg Carton Production Line

Wide range of models for various needs: Capacity ranges from 1,000 to 8,000 pieces per hour, suitable for different production scales.

One-stop system: Complete line includes pulping, forming, drying, stacking, and packing—compact layout and easy operation.

Custom mold support: Molds can be customized for egg trays, fruit trays, coffee cup holders, and other pulp products.

Flexible layout & energy-efficient: Equipment layout can be optimized based on factory space; stable performance with low energy consumption.

Reliable service & timely delivery: We offer model selection advice, installation guidance, operation training, and after-sales support to help customers start production smoothly.

Feel free to contact us for a customized solution based on your capacity, space, and budget needs.

Egg Tray Manufacturing Plant Parameter Details

The model of an egg tray forming machine is usually represented as “Number of Molds × Number of Sides”:

- Number of Molds (first number): The number of molds on each forming side.

- Number of Sides (second number): How many working sides (panels) the machine has.

For example:

- 3×1 means 3 molds on a single side — suitable for small output.

- 5×6 means 6-sided rotary type with 5 molds per side, totaling 30 molds — ideal for high-capacity industrial production.

| Model | Capacity (pcs/hour) |

| 3×1 | 1000-1500 |

| 4×1 | 1500-2000 |

| 3×4 | 2000-2500 |

| 4×4 | 2500-3000 |

| 4×8 | 4000-5000 |

| 5×8 | 5000-6000 |

| 6×8 | 6000-7000 |

| 5×12 | 7000-8000 |

If you’re not sure which model is best for your needs, we’re happy to help based on your required capacity, workshop layout, and budget. Feel free to contact us for a customized solution.