Our scrap metal shredder is an essential machine for recycling plants that need to reduce the size of various metal and waste materials. This equipment uses cutting, tearing, and squeezing forces to process bulky items into smaller, uniform pieces for easy transportation, sorting, or further recycling.

What Is a Scrap Metal Shredder?

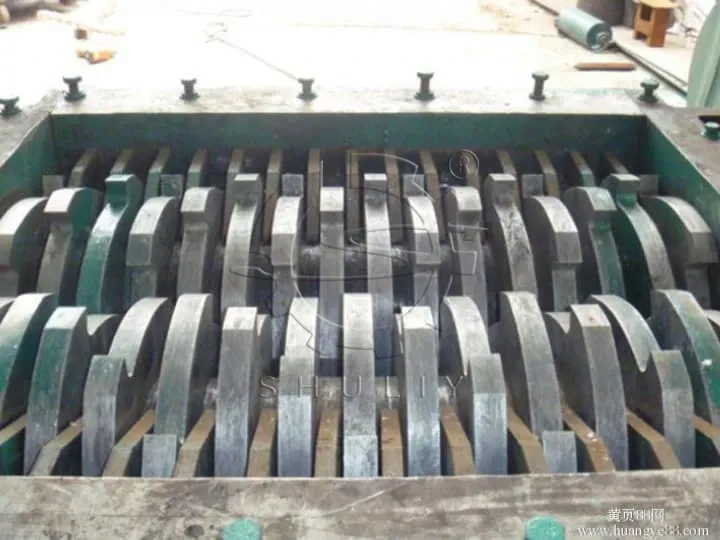

The industrial metal shredder is a multifunctional shredding machine designed to handle a wide range of materials. It works through the combined actions of shredding blades that pull, shear, and compress the material. Once processed, the final output is discharged from the bottom of the shredding chamber.

If needed, customers can add a round screen to control the final size of the shredded material.

Versatile Shredding Capability for Multiple Materials

This double shaft shredder is suitable for a wide range of metal and non-metal waste, making it ideal for recycling plants, scrap yards, and solid waste processing facilities.

Common materials include:

- Aluminum cans and paint buckets

- Steel scraps and light metal waste

- Car shells and motorcycle shells

- Waste household appliance shells

- Large pipes, pipe fittings, forklift pallets

- Tires, aluminum, copper

- Iron materials under 5 mm thickness

- Waste circuit boards and waste cables

Apart from metal waste, the metal recycling shredder can also process municipal waste, household waste, kitchen waste, e-waste, rubber, plastics, and general solid waste. The final output is uniform, and the discharge size can be adjusted when equipped with a screening system.

How Does the Scrap Metal Shredder Work?

Material enters the shredder through the feeding system. Inside the shredding chamber, rotating blades grip and pull the material toward the cutters. With continuous tearing, shearing, and compressing, the material is reduced into small, manageable pieces.

The shredded pieces fall through the bottom outlet or through a screen if size control is required.

How Does A Metal Recycling Shredder Work?

Key Technical Features That Enhance Shredding Efficiency

- Stable performance: Double-shaft design, continuous shredding, uniform output.

- Wide application: Suitable for scrap metal recycling and solid waste processing.

- Customizable discharge size: Optional round screen ring for precise control.

- Drive options: Standard motor drive; diesel engine drive available upon request.

- Large model range: Output capacity from 700–9000 kg/h based on model size.

Available Models and Capacity Range

Our scrap metal shredder series includes multiple models from 600 to 2000. The capacity varies by blade size, motor power, and tool quantity.

Typical capacity range: 700 kg/h – 9000 kg/h

Customers can refer to the technical parameter table to select the proper model based on material type and desired productivity.

Why Choose Our Scrap Metal Shredder?

- Strong shredding capability for both metal and solid waste

- Durable blades and stable transmission system

- Adjustable output size

- Flexible power configuration

- Suitable for various recycling applications

Industrial Metal Shredder for Sale

If you are looking for an industrial metal shredder for sale, we offer a full range of models designed for different capacities and material types. From light metal scrap to bulky industrial waste, our shredders are built with durable blades, stable power systems, and customizable discharge sizes to meet various processing needs.

To help you choose the right model, our sales manager can provide detailed recommendations based on your raw materials and expected output.

Feel free to contact us for a quotation or more information—our engineers are ready to support your project and provide a suitable shredding solution for your facility.

Metal Crushing and Sorting Line (Aluminum Scrap Recycling Line)

This metal shredder can be used not only as a standalone machine but also in combination with a metal crusher, magnetic separator, eddy current separator, metal dry grinding mill, and other equipment to form a complete metal crushing and sorting line.

After shredding and crushing, the material passes through magnetic separation to remove ferrous metals, followed by eddy current separation to sort non-ferrous metals. This integrated system is widely used for aluminum scrap recycling and is also commonly referred to as an aluminum scrap crushing and sorting line, helping improve metal recovery purity and overall processing efficiency.

Related Metal Recycling Equipment You May Be Interested In

In addition to scrap metal shredders, we also supply metal balers and gantry shears to meet the diverse metal recycling requirements of our clientele.

Metal Baler Machine

A metal baler compresses scrap metals into compact, high-density bales for easier transport, storage, and sale. It can handle both light and heavy scrap efficiently. We provide vertical, horizontal baler to fit different processing capacities and site conditions.

Gantry Shears for Scrap Metal

A scrap metal shear is designed for cutting large steel pieces, heavy scrap, and metal plates. Its powerful hydraulic system handles tough materials with ease, making it essential for pre-processing and size reduction. With a sturdy structure and stable performance, it is well-suited for large recycling facilities and scrap processing plants.

Should you wish to learn more about these devices or require technical selection advice, please do not hesitate to contact us. We can provide comprehensive solutions for your metal recycling project.