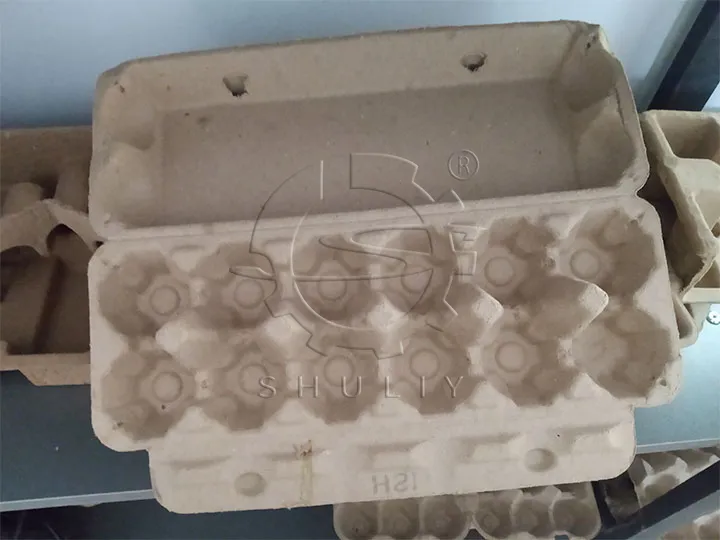

Looking for a reliable egg tray paper pulper machine to recycle waste paper into high-quality pulp? Our advanced pulping system is the perfect solution for businesses producing egg trays, fruit trays, cup holders, and other molded pulp packaging. Designed for consistent performance, easy operation, and sustainable production, this machine is the essential first step in any pulp molding line.

What Is an Egg Tray Pulping Machine?

A paper pulper machine is used to process waste paper—such as newspapers, cardboard, or office paper—into a fine, uniform pulp that serves as the raw material for egg tray production. By mixing paper with water and breaking it down into slurry, the machine prepares pulp suitable for molding into various paper-based packaging products.

It is widely used in:

- Egg tray production plants

- Packaging manufacturers

- Waste paper recycling facilities

- Small-scale and large-scale paper molding lines

Key Features of Our Pulping Machine

- Supports Various Waste Papers – Ideal for newspaper, cardboard, book paper, and more

- Stable Operation – Ensures continuous pulp preparation without clogging

- Uniform Pulp Output – Produces high-quality pulp for better tray forming results

- Durable and Rust-Resistant – Stainless steel construction for long-term use

- Flexible Capacities – The paper pulper machine is selected with a matching capacity based on the output of the egg tray production line

- Easy Integration – Works seamlessly with your forming machine and drying system

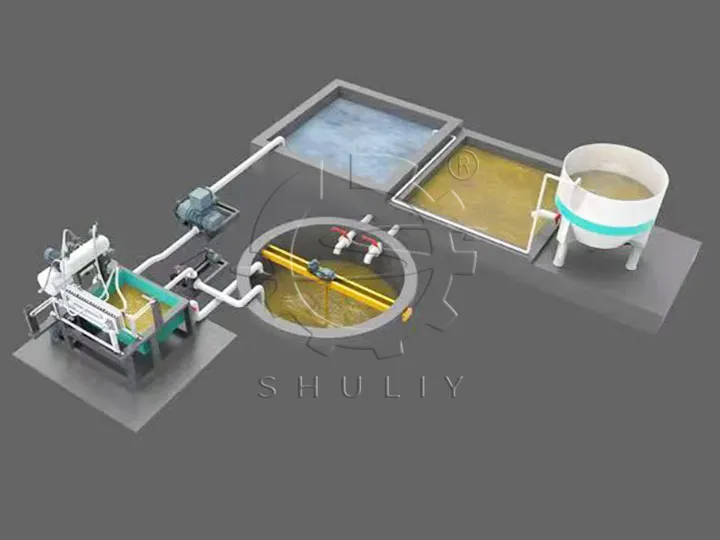

Working Procedures of Pulping System

The paper pulper machine operates in a closed-loop system that efficiently converts raw waste paper into clean pulp:

- Feed the prepared raw materials, such as waste cartons and newspapers, into the hydraulic pulper. Under the action of water shear and friction, the materials are turned into pulp fibers and then transferred to the pulp storage tank.

- Pump the pulp into the first mixing tank, where impurities are filtered out and pulp concentration is adjusted.

- Transfer the adjusted pulp to a second mixing tank for further stirring. Additives like dyes or waterproof agents can be added as needed.

- The prepared pulp is pumped into the egg tray forming machine for molding.

Advantages of Choosing Our Paper Pulper

- Manufacturing Expertise – Over 10 years in pulp molding machine production

- Customizable Solutions – Equipment tailored to your material, capacity, and factory layout

- Global Support – Installation guidance, remote assistance, and spare parts service

- Low Maintenance Design – Simple structure with easy access for cleaning and servicing

Applications Beyond Egg Trays

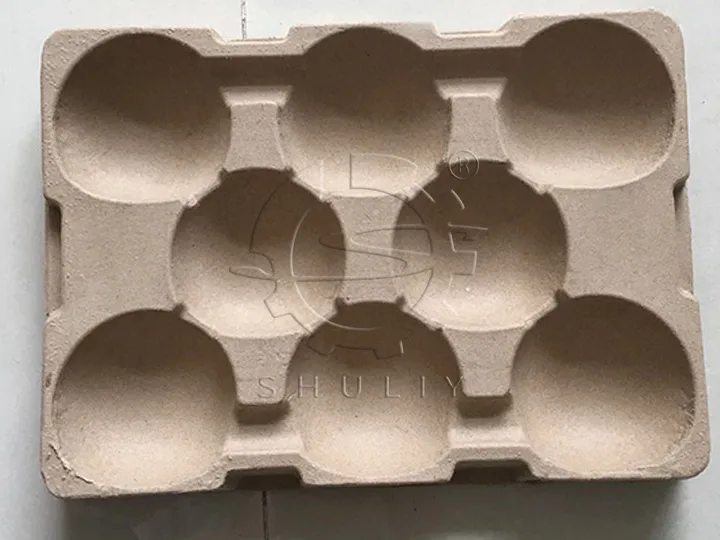

Our egg tray paper pulper machine supports a wide range of molded pulp products, including:

- Fruit trays

- Wine bottle holders

- Coffee cup trays

- Shoe inserts and electronic packaging

It is a versatile investment for any business involved in sustainable paper packaging.

Get Your Customized Egg Tray Production Solution

Ready to start or scale your egg tray production line?

We offer professional advice, tailored machine configurations, and full technical support.

Contact us today to request a free quote or layout recommendation based on your material and capacity.