Waste tire recycling requires efficient pretreatment equipment to make subsequent shredding easier and more cost-effective. The tire dismantling machine is designed to cut and separate tires into manageable parts, reducing wear on shredders and improving recycling efficiency. Depending on tire size and application, we provide two types of dismantling machines: one for standard truck tires up to 1200mm, and one for large OTR (Off-the-Road) tires.

Tire Dismantling Machine for ≤1200mm Tires

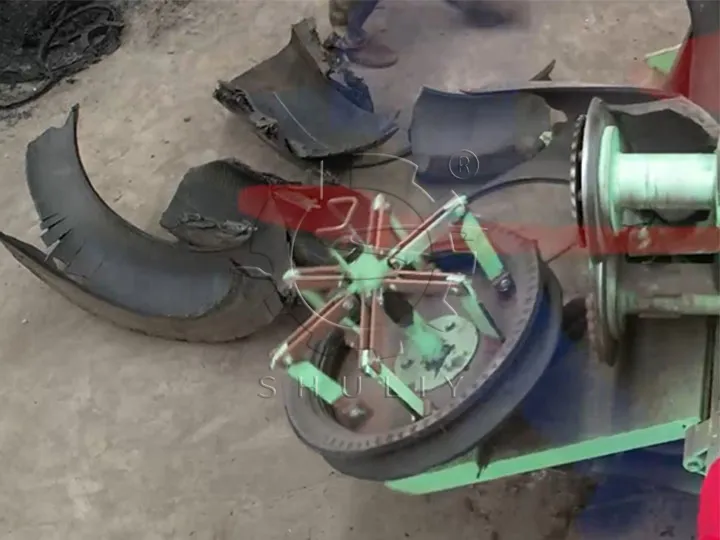

This machine is specially designed for car and truck tires with a diameter of up to 1200mm. It can simultaneously cut off both sidewalls containing steel beads and cut the tire into sections. The removed sidewalls are further processed by a tire steel wire separator to separate steel wires from rubber. The remaining part of the tire can then be directly fed into the tyre shredder for further size reduction.

Technical Specifications of Tire Sidewall Remover and Cutter Machine

- Power: 7.5 + 3 kW

- Processing Capacity: ~3 tons per hour

- Applicable Tire Size: 900–1200mm

- Machine Weight: 1500 kg

- Cutter Material: Cr12MoV high-strength alloy steel

This integrated system not only improves efficiency but also reduces manual labor in tire dismantling.

Tyre Bead Removal and Cutter Machine Working Video

OTR Tire Dismantling Machine

For large engineering and mining tires, we provide specialized OTR tire dismantling machines. These machines cut OTR tires into 4–6 parts (bead, tread, crown, and sidewalls), making them easier to handle and process further.

There are two models available:

For 1400–2000mm OTR Tires

- Power: 7.5 + 5.5 kW

- Processing Capacity: 7–15 minutes per tire

- Weight: 5.6 tons

- Cutter Material: Tungsten carbide alloy

For R35–R63 OTR Tires (2100–4000mm diameter)

- Power: 30.5 kW

- Processing Capacity: 10–30 minutes per tire

- Weight: 9.9 tons

- Cutter Material: Tungsten carbide alloy

Both models ensure safe, efficient dismantling of oversized tires that are otherwise difficult to process.

OTR Dismantling Machine Working Video

Advantages of Tire Dismantling Machines

- Efficient Pretreatment: Tires are dismantled into manageable pieces before shredding.

- Lower Maintenance Costs: Reduces wear and tear on tyre shredding machines.

- High Safety Design: Stable performance with heavy-duty cutting blades.

- Wide Application: Suitable for car tires, truck tires, and extra-large OTR tires.

Contact Us For Further Details On Our Machinery and Solutions

The tire dismantling machine is an essential piece of equipment for modern tire recycling plants. Whether dealing with standard truck tires or massive OTR tires, these machines make the recycling process more efficient and cost-effective. By pre-cutting and separating tires, they not only improve shredding performance but also enhance the quality of downstream recycled rubber.

If you are looking for reliable tire dismantling solutions, our machines offer the perfect combination of efficiency, durability, and safety.