With the rapid replacement of aluminum doors and windows, large quantities of thermal break aluminum scrap are generated from demolition sites, renovation projects, and processing factories. Compared with ordinary aluminum profiles, thermal break aluminum contains plastic insulation strips and mixed non-metal materials, which increases the difficulty of recycling.

Our thermal break aluminum recycling line is specially designed for crushing and separating this complex material. The complete production line mainly includes:

- Metal Shredder

- Scrap Metal Crusher

- Eddy Current Separator

- (Optional) Metal Dry Polishing Machine

This solution focuses on efficient size reduction, effective separation of non-ferrous metals, and improved recycling value.

What Is Thermal Break Aluminum?

Thermal break aluminum profiles are widely used in energy-efficient doors and windows. They combine aluminum alloy with insulating strips to improve thermal insulation performance.

After dismantling, the scrap usually contains:

- Aluminum profiles

- Plastic insulation strips

- Rubber and seal materials

- Small metal accessories

Therefore, a professional crushing and sorting system is required to achieve clean separation and high recovery rates.

Process Overview of the Thermal Break Aluminum Recycling Line

1. Metal Shredder – Primary Size Reduction

The first step is the metal shredding machine, which performs tearing and shearing to reduce the size of bulky materials.

Key features:

- Strong tearing and cutting force

- Suitable for large aluminum profiles and mixed scrap

- Multiple models available according to capacity requirements

- Multi-functional shredder structure for different materials

By reducing the material size in advance, the shredder prepares the material for further crushing and improves overall line efficiency.

2. Metal Crusher – Secondary Crushing to Uniform Size

After shredding, the material enters the scrap metal crusher machine for secondary crushing.

Working principle:

- Hammer heads repeatedly strike the material

- Final discharge size: approximately 3–10 cm

- Output forms: small blocks or small spherical pieces

This step ensures that aluminum and non-metal components are sufficiently separated in structure, creating better conditions for the next separation stage.

3. Eddy Current Separator – Non-Ferrous Metal Separation

The eddy current aluminum separation (also known as copper-aluminum separator or non-ferrous metal eddy current separator) is a new type of automatic metal and non-metal sorting equipment.

Main advantages:

- Excellent separation performance for non-magnetic metals

- Automatically separates non-ferrous metals from non-metal materials

- Suitable for aluminum, copper, and other non-ferrous metals

- Stable operation and adjustable separation parameters

In the thermal break aluminum recycling line, this machine effectively separates aluminum from plastic and other non-metal impurities, significantly improving metal purity and recycling value.

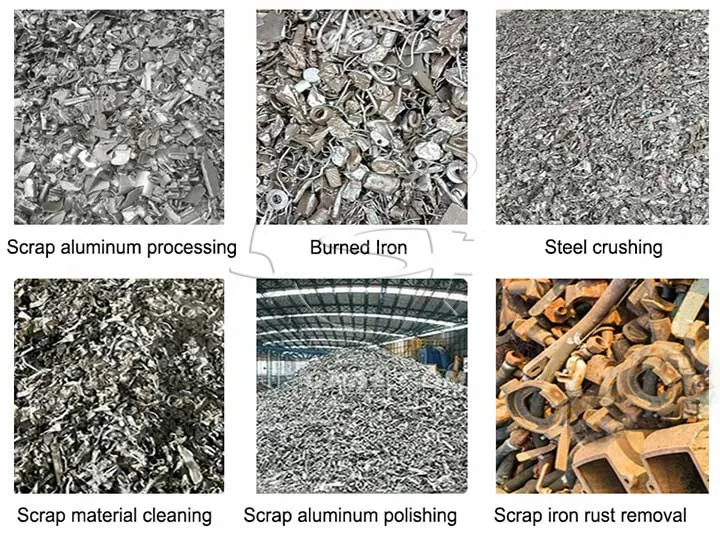

4. Optional Equipment: Metal Dry Polishing Machine

For customers who require higher surface quality of recovered metals, a metal dry polishing machine can be added at the end of the thermal break aluminum recycling line.

Applications:

- Metal parts

- Burnt iron materials

- Crushed scrap

- Non-ferrous metals and non-metal components

Functions:

- Deburring

- Rust removal

- Edge rounding

- Bright polishing

This metal recycling machine is especially suitable for medium or relatively large-sized parts, including easily deformed workpieces. After polishing:

- Original dimensional and geometric accuracy is maintained

- Surface roughness can be improved by 1–2 grades

This step helps enhance the appearance and added value of recycled metal materials.

Thermal Break Aluminum Recycling Line Working Video

Why Choose This Aluminum Recycling Plant?

Instead of purchasing single machines separately, many customers prefer a complete recycling solution that ensures:

- Coordinated equipment design

- Matching capacity between machines

- Stable and continuous production

- Improved separation efficiency

- Better economic return on recycled aluminum

We provide customized configurations based on:

- Raw material condition

- Required processing capacity

- Final product purity requirements

- Factory layout

Suitable Materials Of The Aluminum Scrap Crushing and Sorting Line

Although designed for thermal break aluminum, this thermal break aluminum recycling line is also suitable for:

- Scrap aluminum profiles

- Mixed non-ferrous metal materials

- Crushed metal-plastic composites

- Industrial aluminum scrap

Contact Us for a Waste Aluminum Recycling Equipment Quotation

The thermal break aluminum recycling line integrates shredding, crushing, and eddy current separation into a complete and practical solution. By effectively reducing material size and separating non-ferrous metals from non-metal components, it helps recycling plants improve aluminum purity and overall profitability.

If you are planning to upgrade your aluminum recycling process or build a new thermal break aluminum recycling project, feel free to contact us for a tailored configuration and technical proposal.