Rotary drum polishing machine is a dry grinding and polishing solution we commonly recommend to customers who need reliable surface finishing for metal and mixed materials. Also known as a metal dry grinding machine or drum-type polishing equipment, this machine is mainly used for deburring, rust removal, edge rounding, and bright polishing of various metal and non-metal parts.

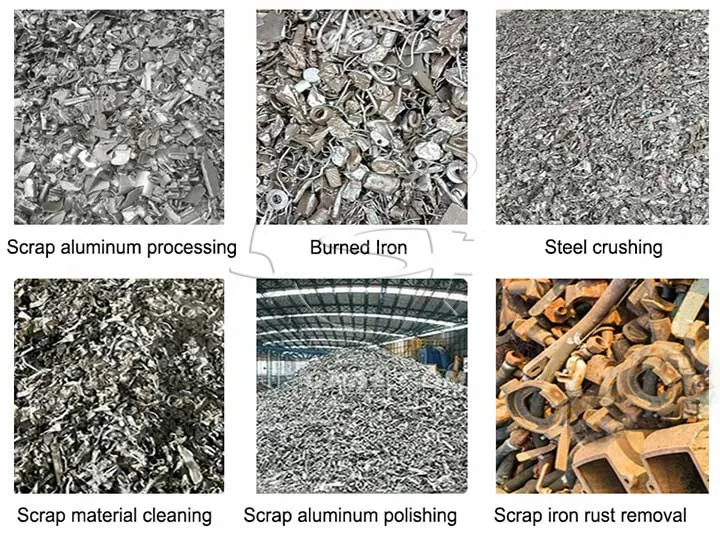

In practical applications, it is widely used for metal, burnt iron from power plants, crushed materials, stainless steel, scrap aluminum, oily parts, scrap steel, non-ferrous metals, and non-metal components, especially in recycling and material upgrading processes.

What Problems This Machine Helps Customers Solve

From our experience working with recycling plants and metal processing companies, many customers face similar challenges:

Materials with oil, rust, sharp edges, or rough surfaces that reduce resale value or make further processing difficult.

The rotary drum polishing machine is designed to address these issues through a dry grinding process. After treatment, parts not only retain their original shape and dimensional accuracy, but their surface finish can be improved by 1–2 roughness grades, helping customers achieve cleaner and more uniform finished materials.

This scrap metal polishing machine is particularly suitable for easily deformable workpieces and for medium to large-sized parts that require stable and consistent surface finishing.

Typical Application Materials for The Scrap Metal Polishing Machine

Based on actual customer usage, this rotary drum polishing machine is commonly applied to:

- Burnt iron crushed material from power plants

- Scrap steel and crushed metal materials

- Stainless steel parts

- Scrap aluminum and aluminum parts

- Oily and rusty metal components

- Copper and aluminum crushed materials

- Non-ferrous metal and non-metal product parts

For customers operating metal recycling or sorting lines, the rotary drum polishing machine for scrap metal recycling is often used as a downstream process to improve material cleanliness and appearance.

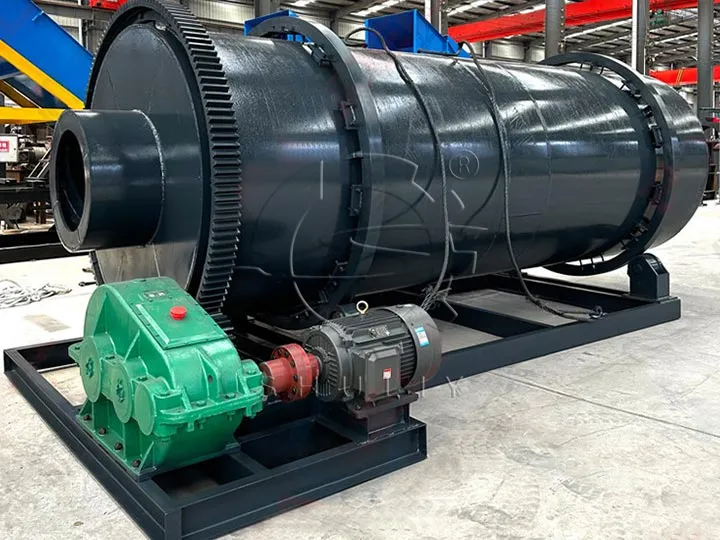

Working Principle of the Scrap Metal Polishing Drum

The metal dry grinding machine is suitable for polishing and rust removal of metal and scrap aluminum materials with a diameter of less than 400 mm, especially those containing oil and rust.

The electric motor drives a reducer, which rotates the drum. Inside the drum, guide plates and turbulence plates are installed. During operation, materials and grinding media are conveyed into the drum through a feeding system. As the drum rotates, materials and grinding media continuously tumble, collide, rub, and mix with each other.

Through this repeated throwing and friction process, the grinding media fully absorb oil stains and rust from the surface of the materials, achieving effective degreasing and rust removal without the use of liquids.

Working Video of The Metal Processing Machine

Key Structural Features for Stable Operation

High-Strength Aperture Gear

The aperture gear is made of high-strength alloy steel and formed by one-piece casting. This structure provides higher stability and ensures reliable operation during long-term use.

Wear-Resistant Machine Body

The machine body of the rotary drum polishing machine is manufactured using extra-thick steel plates, combined with high-standard welding and polishing processes. This design improves durability and ensures safe, long-lasting operation in industrial environments.

Enlarged Hopper for Even Feeding

An enlarged feeding hopper allows materials to enter the drum evenly, helping avoid uneven processing and ensuring stable output during continuous operation.

How This Machine Fits into Recycling and Processing Lines

In many customer projects, the rotary drum polishing machine is not used alone. It is often integrated into aluminum scrap crushing and sorting lines, working after metal shredder, scrap metal crusher machine and eddy current sorting machine to further improve material quality.

By removing rust, oil, and surface burrs, the machine helps customers increase the value and usability of recovered materials before storage, sale, or further processing.

A Practical Surface Finishing Solution for Metal Materials

From a supplier’s perspective, the rotary drum polishing machine is a practical and reliable choice for customers who need stable dry grinding and polishing of metal and mixed materials. It offers effective rust removal, deburring, and surface improvement while maintaining part integrity and dimensional accuracy.

If you are processing burnt iron, scrap metal, aluminum, or other mixed materials and need a consistent surface finishing solution, this machine can be configured to match your material conditions and production requirements. We are always ready to assist you in selecting the right setup for your application.