In the pulp molding industry, a standard production line for egg trays or industrial packaging can produce finished goods right after the drying stage. However, for high-end markets that demand superior quality, a premium appearance, and enhanced functionality, an additional process is essential: hot pressing. The Paper Tray Hot Pressing Machine is the key piece of equipment that performs this crucial finishing touch.

Dried paper trays typically have a relatively rough surface and may have minor dimensional variations. A hot pressing machine applies high temperature and high pressure to the dry trays, performing a secondary shaping and calendering process. This results in a smoother surface, sharper edges, higher density, and more precise dimensions. This is not just for aesthetics; it is vital for meeting the functional requirements of specific applications, such as automatic labeling, precision stacking, and enhancing brand image.

The Core Value of Hot Pressing Machine

Investing in a pulp molding hot press machine means you can penetrate markets with higher standards for product detail. The core advantages it delivers include:

- Superior Surface Finish: After hot pressing, the paper tray surface becomes exceptionally smooth and flat, eliminating the rough texture of raw paper fibers.

- Increased Density and Strength: The high pressure compacts the internal fiber structure of the tray, thereby improving its overall density, hardness, and compressive strength.

- Precise Dimensions and Shape: The hot press mold can accurately calibrate the product’s contour, ensuring that every piece has highly consistent dimensions and shape.

- Enhanced Stackability: Egg cartons or industrial trays that have been hot-pressed feature neat edges and flat surfaces. This allows for tighter, more stable stacking, which in turn saves valuable warehouse space and reduces transportation costs.

Key Features and Benefits of Hot Press Machine

Customized Mold Design and Manufacturing

Our technical team can design and fabricate high-precision hot press molds that perfectly match your product drawings or samples. The molds are made from high-grade tool steel, which is heat-treated and precision-machined to ensure durability and excellent shaping performance.

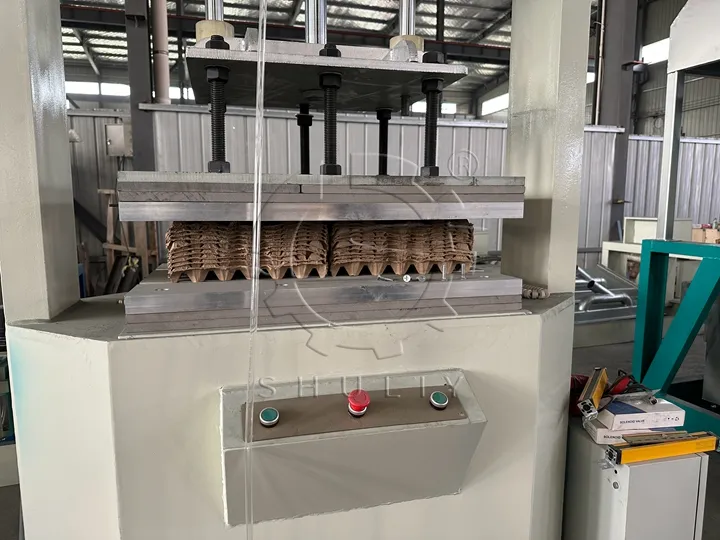

Robust and Durable Construction

The machine frame is constructed from heavy-duty steel plates, welded and then stress-relieved through an aging treatment to ensure long-term stability without deformation under high pressure.

User-Friendly Operation and Safety

The equipment features a clear and intuitive control panel (PLC and touch screen are optional), allowing operators to easily set the temperature, pressure, and holding time. We have also integrated comprehensive safety features, such as dual-hand start buttons, safety light curtains, and emergency stop switches, to fully protect the operator.

How It Works: The Hot Pressing Process Explained

The workflow of our egg tray hot pressing machine is simple and efficient:

- Place the Product: The operator places a fully dried paper tray onto the lower hot press mold.

- Initiate Pressing: The operator presses the start buttons, and the upper mold automatically descends to close with the lower mold.

- Heat and Press: For a preset duration, the molds apply constant high temperature and pressure to the tray. The heat softens the paper fibers, and the pressure reshapes and compacts them.

- Open and Retrieve: After the holding time is complete, the upper mold automatically retracts, and the operator removes the finished product, now with a smooth, perfectly formed surface.

The entire cycle typically takes only a few seconds, ensuring high efficiency that can match the pace of your production line.

Contact Us for a Complete Egg Tray Making Solution

As a professional manufacturer of paper egg tray machine, we offer more than just individual machines; we are dedicated to building a complete and efficient egg tray production line for you, from raw materials to finished products. Our turnkey solution covers every core stage of production: from high-efficiency pulping machines and reliable egg tray forming machines to versatile drying systems, all the way to the final automatic stacking packaging machines and hot pressing machines.

Regardless of your operational scale, our team of experts will tailor the optimal equipment configuration based on your specific capacity, factory conditions, and budget, ensuring seamless integration between all units to maximize production efficiency. Contact us today for a free technical consultation and one-stop project planning services.