Our metal baler machine is a core piece of equipment designed for the recycling industry and metal smelters, engineered to compress loose scrap metal into dense, manageable bales. This process dramatically saves storage space, significantly reduces transportation costs, and simplifies feeding materials into furnaces for recycling.

Processable Material Range of the Scrap Metal Press

Our powerful hydraulic metal balers are versatile and capable of efficiently processing a wide variety of ferrous and non-ferrous scrap metals. Common materials include:

- Steel shavings and iron turnings

- Scrap steel and metal offcuts

- Scrap aluminum, aluminum chips, and used beverage cans (UBCs)

- Scrap copper wire and copper remnants

- Dismantled car shells (ELVs) and used oil drums

Horizontal vs. Vertical Balers: Solutions for Every Need

To meet diverse operational scales and material types, we offer two primary configurations of metal compactors: horizontal and vertical.

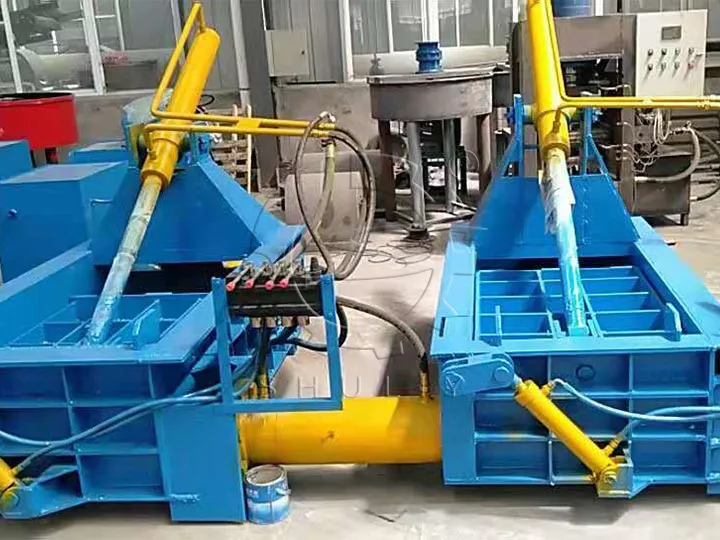

Horizontal Metal Baler Machine

The horizontal baler is the ideal solution for processing large volumes of heavy-duty scrap, making it a staple in large scrap yards and metal fabrication facilities. e offer various bale discharge methods, including forward-push, side-push, and turn-out (tipping), to seamlessly integrate into different production lines.

Vertical Metal Baler

With a smaller footprint and compact design, the vertical metal baler machine is perfect for facilities with limited space or smaller processing volumes. They are the preferred choice for compacting lighter materials, especially aluminum cans and other lightweight aluminum scrap.

Core Technology and Key Features of Aluminium Can Baler

All our metal baler machines are equipped with a robust hydraulic drive system, ensuring smooth operation, powerful compression, and reliable performance. Clients can choose between manual valve operation or a fully automatic PLC control system to suit their operational preferences.

We offers a wide range of pressing forces, from 63 to over 600 tons, to meet specific requirements for bale density and size. The chamber dimensions and final bale shape (e.g., rectangular, octagonal) can be customized based on your raw materials and furnace specifications. Furthermore, for operations in locations without a stable power supply, we offer a diesel engine power option for enhanced mobility and versatility.

Scrap Metal Baling Machine Working Video

How to Choose the Right Baler for Your Needs

Selecting the appropriate scrap metal baler machine depends on a few key factors:

- Material Type and Volume: What kind of scrap will you primarily process? What is your expected daily tonnage?

- Operational Space: What are the spatial constraints of your facility?

- Bale Specifications: What are your required bale dimensions, weight, and density?

Other Metal Recycling Equipment

In addition to our high-performance scrap metal baler machines, we also offer other metal recycling machinery for processing scrap metal.

- Scrap Metal Shear: Our heavy-duty gantry shears are designed for cutting oversized and heavy scrap metal, such as structural steel, rebar, plates, and pipes, into furnace-ready sizes.

- Metal Shredders: Our industrial metal shredders are built to achieve significant volume reduction and material liberation. They can process a wide range of materials, including car bodies, aluminum profiles, and e-waste, by tearing them into small, consistent pieces for easier sorting and melting.

Should you require our metal scrap baling press machines or related metal recycling equipment, please feel free to leave a message on our website. Our sales manager will contact you at the earliest opportunity.