In the egg tray production process, the egg tray making machine is one of the most crucial pieces of equipment. Our company specializes in providing a full range of egg tray forming machines to meet various customer needs in terms of capacity, automation level, and budget. This article introduces the working principle, raw materials, finished products, model options, and pricing of our egg tray machines to help you find the ideal solution for your production.

What Is an Egg Tray Forming Machine?

An egg tray molding machine is used to mold paper pulp into egg trays, fruit trays, and other pulp packaging products. It is widely used for packaging chicken eggs, duck eggs, quail eggs, and can also produce paper cup holders and fruit trays.

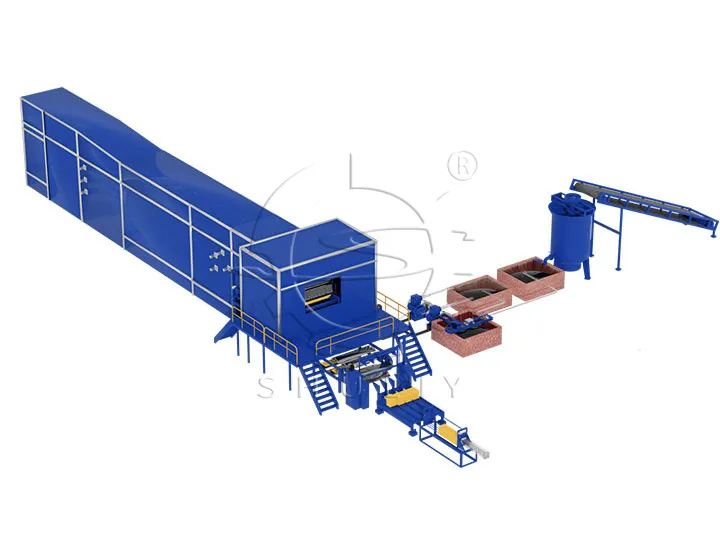

Our machines use advanced mold forming technology and can be integrated with pulping systems, drying systems, stacking, and packing units to form a complete egg tray production line.

Applicable Raw Materials and Final Products

Our egg tray making machines are suitable for various types of waste paper, such as:

- Newspapers

- Used cardboard

- Kraft paper

- Magazines and books

- 30-cell egg trays (most common)

- 6-cell, 12-cell egg cartons

- Trays for duck and quail eggs

- Disposable paper cup holders

- Fruit trays and industrial paper trays

Egg trays and other types of paper trays are mainly used to support and protect items such as eggs, fruits, and cups, preventing breakage or damage during transportation and handling. They effectively secure products in place and provide excellent cushioning, making them an ideal eco-friendly packaging solution for fragile items.

Egg Tray Production Process Overview

The egg tray manufacturing process includes the following steps:

- Pulp Preparation: Waste paper and water are mixed and crushed by a pulping system to create uniform paper pulp.

- Pulp Molding: The pulp is vacuum-formed on metal molds using the egg tray making machine.

- Drying: The wet trays are sent through a drying system to remove excess moisture and finalize their shape.

- Shaping & Packing: Optional hot-pressing machines enhance appearance; the trays are then packed by a packing machine.

Working Principle of the Egg Tray Molding Machine

Our egg tray making machines use a vacuum suction molding process: pulp is sucked onto molds using a vacuum pump, shaped under pressure, and then released by air blow or a mechanical push-off system.

The entire operation is highly automated, offering consistent product quality, high efficiency, and low energy consumption.

Advantages of Our Egg Tray Making Machines

- Customizable Molds: Molds can be tailored to your product needs, such as 12-cell, 20-cell, or 30-cell egg trays.

- Various Automation Options: Manual, semi-automatic, and fully automatic systems are available.

- Various models, wide range of output: Our egg tray forming machine has 8 models, with output ranging from 1000pcs/h-8000pcs/h, to meet the production needs of various customers.

- Installation Support: We offer on-site or remote installation guidance and technical support to ensure smooth production start-up.

Various Models of Egg Tray Maker Machine

With years of experience in manufacturing egg tray making machines, we offer a wide range of models with different capacities to meet various production needs. Our machines include:

- Single-side egg tray machines: 1,000–1500 pieces/hour

- Four-side machines: 2,000–3,000 pieces/hour

- Eight-side machines: 4,000–7,000 pieces/hour

- Twelve-side machines: 7,000–8,000 pieces/hour

All our machines are built with high quality and offered at competitive prices. Custom designs are also available to suit your specific requirements. Feel free to contact us for more information.

Single Sided Egg Tray Machine

Four-side Egg Tray Maker Machine

Eight-sided Egg Carton Machine

12 Sided Egg Tray Making Machine

Paper Egg Tray Machine Price

When choosing an automatic egg tray making machine to start your business, the price is undoubtedly one of your top concerns. The price of our egg tray forming machines varies depending on the model, level of automation, and supporting systems such as the drying line and packing unit.

Once we understand your needs and customize a suitable solution, we will provide you with a detailed quotation. Our machines are competitively priced, and we offer reasonable discounts. If you’re interested, feel free to leave a message on our website — our sales manager will get in touch with you shortly.

Partner with a Reliable Egg Tray Machine Manufacturer

As an experienced egg tray making machine manufacturer, we have successfully delivered egg tray production lines to clients across the globe, ranging from pilot projects to large-scale export businesses. We offer full support including technical consultation, layout design, installation guidance, and long-term after-sales service.

If you’re planning to start or expand your egg tray production, feel free to contact us for a free consultation and quotation.