In the pulp molding industry, a complete egg tray production line consists of four core stages: pulping, forming, drying, and hot-pressing/packing. Among these, the drying stage is not only directly linked to production efficiency but also determines the final quality, strength, and appearance of the egg trays. An efficient and stable egg tray drying system is the cornerstone for ensuring a return on investment and achieving large-scale production.

Freshly molded egg trays coming from the egg tray forming machine contain approximately 70-75% moisture. This moisture content must be reduced to 10-12% through an effective drying process to obtain strong, durable finished products. Improper drying can lead to product warping, uneven shrinkage, insufficient strength, or even mold, resulting in significant material and energy waste. Therefore, understanding and selecting the most suitable egg tray drying method for your specific needs is critically important.

An In-Depth Analysis of Mainstream Egg Tray Drying Methods

Depending on production scale, investment budget, site conditions, and available energy sources, there are three egg tray drying systems for drying egg trays. We will analyze the pros and cons of each to help you make an informed decision.

1. Natural Drying (Sun Drying)

Best Suited For:

- Small-scale or home-based operations (e.g., capacity under 1000 pieces per hour).

- Regions with a consistently hot, dry, and sunny climate.

- Areas where land and labor costs are extremely low.

Advantages:

- Zero Initial Equipment Investment: No need to purchase expensive drying equipment.

- Zero Energy Consumption: Relies entirely on natural energy, resulting in no fuel costs.

Disadvantages:

- Highly Dependent on Weather: Production halts on rainy or humid days, leading to highly unstable efficiency.

- Requires a Large Footprint: A significant amount of space is needed to set up the drying racks.

- Long Drying Cycle: The process can take several hours or even longer, severely limiting production capacity.

- Sanitation Risks: Open-air exposure can lead to contamination from dust, insects, and birds.

- High Labor Costs: Requires extensive manual labor for moving, turning, and collecting the trays.

2. Traditional Brick Kiln Drying System

The brick kiln egg tray drying system is a common choice for semi-automatic egg tray manufacturing plants. This method requires constructing a 30-60 meter long tunnel-like drying kiln on-site using bricks and cement. Wet egg trays travel through the tunnel on a slow-moving conveyor belt, heated by burning fuel such as coal, wood, natural gas, or diesel.

Best Suited For:

- Medium-scale production (e.g., 1500-4000 pieces per hour).

- Investors who require a degree of automation but have a limited budget for a fully automatic system.

- Facilities where civil construction is feasible.

Advantages:

- Stable Production Capacity: Unaffected by weather, allowing for continuous operation.

- Moderate Equipment Investment: The initial civil engineering cost is lower compared to a full metal drying system.

Disadvantages:

- Lower Thermal Efficiency: The insulation of brick structures is often poor, leading to significant heat loss and higher fuel consumption.

- Uneven Temperature Distribution: Inconsistent temperature inside the kiln can cause some trays to be over-dried while others remain under-dried, affecting product consistency.

- Long Construction Period: On-site construction is time-consuming.

- Difficult Maintenance: Repairing the internal structure can be challenging if it gets damaged.

- Environmental and Emissions Concerns: Using fuels like coal or wood may face strict environmental regulations.

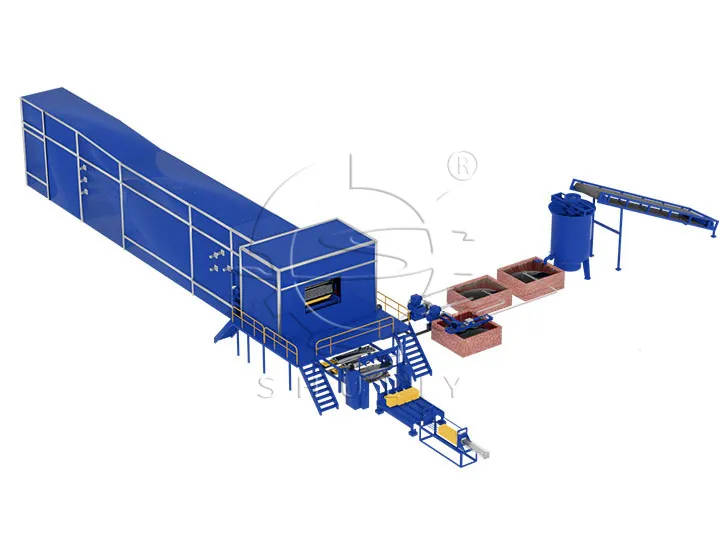

Our Solution: Multi-layer Metal Drying System

To overcome the shortcomings of traditional drying methods, we have developed and introduced the modern multi-layer metal drying system. This is an integrated, automated, and high-performance solution designed for modern egg tray manufacturers who prioritize high quality, low operational costs, and a compact layout.

Our metal egg tray drying system is a fully enclosed chamber constructed from high-quality steel and premium insulation materials. Inside, a multi-layer (typically 6 or 8 layers) conveyor chain system made of metal mesh circulates the trays efficiently and evenly through the heated, enclosed space.

Key Features & Benefits

Ultimate Space Utilization (Compact Footprint)

The multi-layer track design maximizes the drying path within a limited length and height. Compared to a brick kiln dryer of the same capacity, our metal drying system can save over 50% of floor space, adding more value to your precious factory area.

High Thermal Efficiency (Excellent Energy Savings)

The system features double-layer insulation panels filled with high-efficiency thermal insulation material (like rock wool) to minimize heat loss. Combined with an advanced hot air circulation system, it achieves superior thermal efficiency, saving over 30% in fuel costs compared to a traditional brick kiln.

Superior Product Quality (Perfect Consistency)

Equipped with a precise automatic temperature control system and a variable-frequency drive for the conveyor, you can accurately adjust the drying temperature and speed. This egg tray drying system ensures every egg tray is heated uniformly under optimal conditions, resulting in a perfectly formed, warp-free product with consistent strength.

Fully Automatic Operation (Reduces Labor Costs)

The entire process, from wet tray infeed to dry tray outfeed, is fully automated, requiring no manual intervention. This not only significantly reduces labor intensity and costs but also prevents product damage that can occur during manual handling.

Egg Tray Making Machine For Sale

Choosing an egg tray drying system is more than just buying a piece of equipment; it is a crucial investment in your company’s long-term profitability and market competitiveness.

- For start-ups or projects with extremely tight budgets, natural drying can be a viable starting point.

- For customers with moderate production needs who can accommodate civil works, the brick kiln dryer is a transitional option.

- However, for any modern enterprise seeking long-term operational stability, premium product quality, reduced operational costs, and full automation, our Multi-layer Metal Drying System is undoubtedly the most ideal solution on the market today.

We provide more than just machinery; we offer comprehensive technical consultation. Our team of experts will work with you to design a custom-tailored egg tray drying solution based on your specific capacity requirements, factory layout, and energy resources.

Contact us today to receive a free technical proposal and a customized quote for your egg tray production line!