Metal crusher is a versatile machine designed for crushing and processing various types of scrap metal materials. It can be used as a standalone unit or combined with metal shredders, eddy current separators, metal dry grinding mills, and other equipment to form a complete metal crushing and sorting line, also known as a scrap metal or aluminum recycling line.

Wide Application, Effortlessly Handling Diverse Materials

The metal scrap crusher has powerful crushing capabilities, able to process over 200 different types of metal materials, making it an ideal choice for scrap metal reprocessing, scrap metal treatment centers, steel mill subsidiaries, and scrap metal recycling enterprises.

Its main applicable materials include:

- Scrap Vehicles: Flattened car bodies, dismantled auto parts, etc.

- Lightweight Materials: Light and thin metals that have been sheared or baled, with a density not exceeding 1t/m³.

- Home Appliances: Old washing machines, refrigerators, air conditioners, colored steel tiles, etc.

- Vehicle Body Parts: Frames and other parts from scrap motorcycles, electric bikes, and bicycles.

- Various Containers: Waste aluminum cans, paint buckets, scrap aluminum, etc.

- Other Scrap Materials: Scrap iron sheets, scrap steel, scrap iron, old metal, thermal break aluminum doors and windows, radiators, etc.

Uniform Output Size and Customizable Discharge

The discharged material is mainly in small spherical or granular form, with an output size of 3–10 mm. The discharge size can be customized according to specific processing requirements. The metal crusher is equipped with conveyors at both the feeding and discharging ends, ensuring smooth and continuous material handling.

For thin-walled metals such as aluminum cans, the crushed material is mostly formed into regular spherical shapes, while thicker metal materials are mainly discharged in flake or small block form. The output shape matches the material characteristics, making it convenient for subsequent sorting and recycling processes.

Aluminum Crusher Operation Video

Advantages and Key Features of the Metal Crusher

- Wide Processing Capacity Range: The machine offers a processing capacity from 600 to 18,000 kg/h, meeting the production needs of different-scale scrap metal recycling projects, from small recycling facilities to large centralized processing lines.

- Flexible Cutter Configuration: The thickness of the cutters and the number of claws can be adjusted or replaced according to different metal materials, helping improve crushing efficiency and ensure stable output quality.

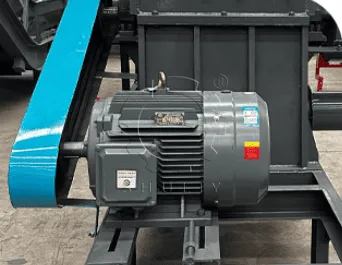

- Fully Automated Operation: The metal crusher supports fully automated operation with stable and continuous performance, reducing manual intervention, improving productivity, and lowering labor costs.

- All-Copper Motor for Energy Efficiency: Equipped with an all-copper core motor, the machine reduces energy consumption, operates reliably, and provides a long service life suitable for continuous operation.

- Multiple Safety Protection Systems: The metal scrap crusher is equipped with motor overload protection and a power interlock system to prevent abnormal operation and ensure operator safety.

- Sealed Feeding Design to Prevent Material Splashing: Thickened body plates combined with a sealed feed inlet effectively prevent crushed material from flying out, improving on-site safety and cleanliness.

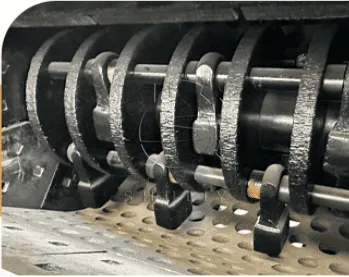

Heavy-Duty Structure and Reliable Crushing Design

The metal crusher machine body is manufactured with extra-thick steel plates and reinforced with inclined supports, ensuring stable operation under heavy load and high-impact crushing conditions. The crusher adopts a hammer crushing method. Both liners and hammer heads are made of high-strength manganese steel, providing excellent wear resistance and extended service life.

The hammer heads are installed in a movable design, delivering strong crushing force. When non-crushable materials enter the crushing chamber, the hammers can swing away flexibly, allowing the material to be discharged through a dedicated outlet, reducing damage to the machine and improving operational safety.

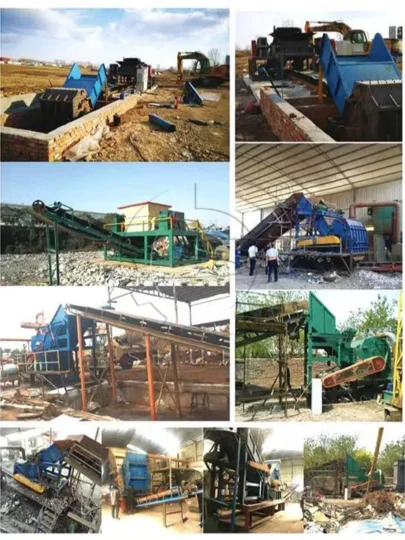

Flexible Configuration: Standalone or Complete Sorting Line

The metal crusher can operate independently for direct size reduction of metal materials. For higher recovery efficiency and better metal separation, it can also be integrated with a metal shredder, magnetic separator, eddy current separator, and metal dry mill to build a metal crushing and sorting line. This system enables efficient crushing, separation, and recycling of ferrous and non-ferrous metals.

Main Technical Parameters of Metal Crusher

| Model | Power (kW) | Speed (r/min) | Capacity (kg/h) | Dimensions (mm) |

| SL-600 | 18.5–22 | 860 | 600–800 | 2000 × 1200 × 1900 |

| SL-800 | 30–37 | 860 | 800–1000 | 2200 × 1500 × 2200 |

| SL-1000 | 55–75 | 860 | 2500–3500 | 2800 × 1900 × 3100 |

| SL-1300 | 90–110 | 750 | 3500–5000 | 3500 × 2100 × 3800 |

| SL-1600 | 110 × 2 | 750 | 4000–8000 | 4400 × 2500 × 4200 |

| SL-1800 | 160 × 2 | 650 | 8000–12000 | 4700 × 2900 × 4500 |

| SL-2000 | 220 × 2 | 650 | 10000–18000 | 5000 × 3200 × 4600 |

Metal Crusher Machine for Sale

Our metal crusher machine for sale is designed to meet the practical needs of scrap metal recycling projects of different scales. With multiple models available, the processing capacity ranges from 600 kg/h to 18,000 kg/h, allowing customers to choose suitable equipment based on their material type and production requirements.

The machine can be used independently or integrated into a complete metal crushing and sorting line. Stable performance, durable structure, and flexible configuration make it a reliable option for long-term metal recycling operations. For detailed specifications, pricing, and customized solutions, feel free to contact us for more information.