The rubber cracker mill is a key equipment in the waste tire recycling line. It is mainly used to grind tire blocks or shredded rubber pieces into fine rubber powder or granules. The machine is equipped with a screening system to control the final powder size and a magnetic separator to remove small steel wires from the material, ensuring high purity rubber output.

Application of the Rubber Powder Mill

This rubber crusher is widely used in tire recycling plants, rubber processing factories, and waste management centers. It processes tire blocks produced by a tire shredder or tire block cutter, turning them into rubber powder that can be reused in rubber products manufacturing, asphalt modification, and other recycling applications.

Working Principle of Rubber Cracker Mill

The rubber powder making machine adopts mechanical grinding technology. Rubber blocks are fed into the grinding chamber, where rotating rollers grind the material into fine particles. The built-in vibration screen system classifies the material and ensures that the final size meets production requirements.

To ensure the quality of the final rubber powder, the rubber powder production line incorporates a magnetic separation stage. This efficiently removes minute steel particles separated during the grinding process, guaranteeing the rubber powder’s purity meets the stringent requirements of high-standard applications.

Working Video of The Rubber Crusher

Features and Advantages of Cracker Mill Rubber

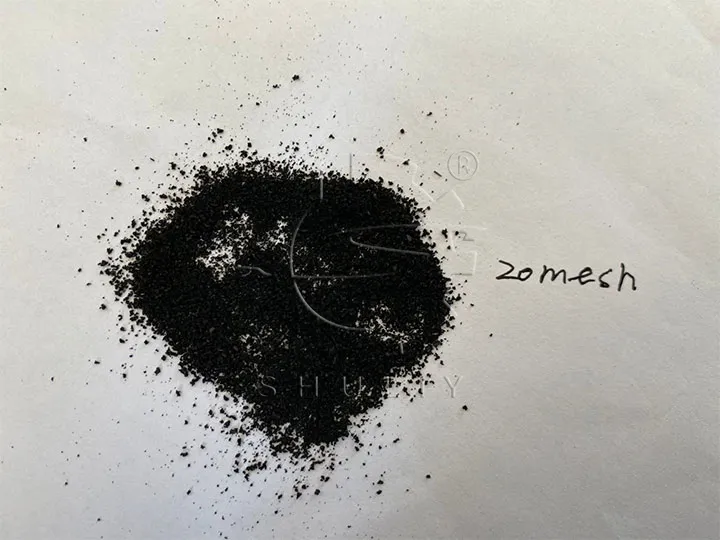

- Fine powder output: Adjustable screen mesh allows control of final particle size (typically 10–40 mesh).

- High efficiency: Designed for continuous operation with stable performance.

- Integrated magnetic separation: Removes residual steel wires for cleaner rubber powder.

- Durable structure: Made from wear-resistant materials for long service life.

- Low noise and vibration: Optimized design reduces operational noise and improves stability.

- Production capacity advantage: We offer a diverse range of models, customisable to meet clients’ specific rubber dimensions and production capacity requirements.

Rubber Powder Making Capacity

Customers may select the appropriate rubber cracker mill model based on their required rubber powder fineness and production output. This series offers multiple models to accommodate production requirements of varying scales. It is worth noting that finer rubber powder yields lower production output.

| Model | 10mesh (2.5mm) | 20mesh (1.25mm) | 30mesh (0.83mm) | 40mesh (0.63mm) |

| SL-350 | 250-300 kg/h | 180-230 kg/h | 150-210 kg/h | 80-120 kg/h |

| SL-400 | 400-500 kg/h | 300-350 kg/h | 240-280 kg/h | 150-175 kg/h |

| SL-450 | 500-600 kg/h | 400-500 kg/h | 350-450 kg/h | 200-250 kg/h |

| SL-560 | 900-1000 kg/h | 600-700 kg/h | 450-550 kg/h | 300-350 kg/h |

| SL-560D | 1500-1600 kg/h | 1200-1300 kg/h | 1000-1100 kg/h | 800-900 kg/h |

| SL-660 | 2100-2300 kg/h | 1600-1700 kg/h | 1200-1300 kg/h | 900-1000 kg/h |

Customized Rubber Cracker Mill

We provide flexible customized services to meet the diverse production conditions and material characteristics of different customers.

The rubber cracker mill can be customized according to the local power supply standards of the customer’s country or region, including voltage, frequency, and motor configuration, ensuring stable operation in local environments.

Our technical team will recommend or design the most suitable Rubber Powder Production Line solution based on the size of the raw materials (such as tire block dimensions or shredded particle size) and the desired production capacity.

In addition, we can provide a layout design, installation guidance, and operation training according to the customer’s site layout, ensuring fast commissioning and stable operation of the production line.

Through our integrated design, manufacturing, and after-sales service, we are committed to providing customers with economical, efficient, and energy-saving tire recycling solutions.