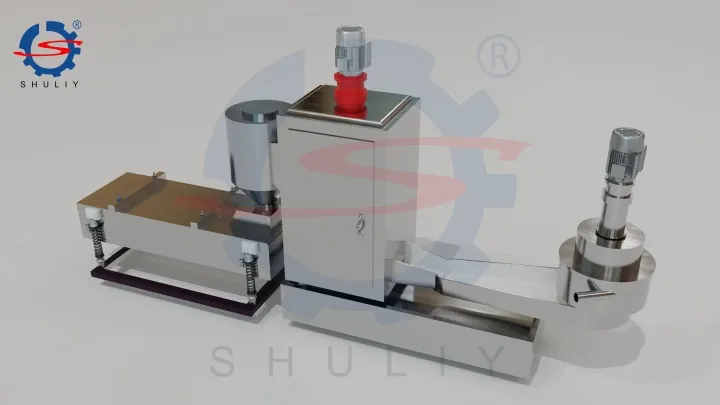

塑料达纳切粒机又称塑料颗粒切粒机,是一种塑料切粒机,用于将塑料造粒机挤出的塑料条切成均匀尺寸的塑料颗粒。 Shuliy是一家专业的塑料达纳切割机制造商。我们的塑料机械已出口到多个国家,并已为他们创造了可观的利润。

塑料切粒机介绍

塑料颗粒切割机是塑料回收和造粒过程中不可或缺的重要设备,主要用于将熔融状态下挤出的塑料条切割成均匀的颗粒,广泛应用于PP、PE、PET、PS、ABS、PA等各种塑料材料的造粒加工。

德纳切割机特点

- 切割颗粒尺寸约3mm,可调;

- 采用硬质合金滚刀,刀片寿命长,每切割2000吨颗粒更换一次;

- 可配备振动筛,确保颗粒均匀、优质;

- 提供水环切割装置,满足多样化需求。

塑料达纳切割机如何工作?

- 首先,将挤出的塑料条通过入口送入塑料切条机内部。

- 材料进入塑条切割机后,受到上下压轮的压制,使其保持稳定状态,准备切割。

- 在压力的作用下,旋切刀开始快速旋转。旋转刀具锋利的刀刃将材料切割成所需的均匀颗粒。

- 切割后的塑料达纳切割机将从机器的排料口排出。

- 如果背面安装振动筛,可以防止颗粒粘附并去除成型颗粒。

塑料颗粒切割机应用视频

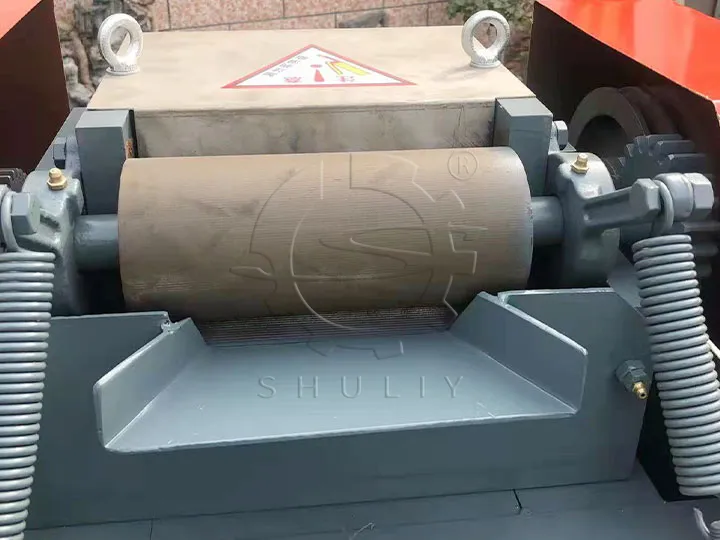

塑料达纳切割机刀片

塑料达纳切割机的刀采用滚刀设计,这意味着它使用旋转的滚轮来执行切割工作。这种设计通常可以有效地将塑料颗粒或条材切割成所需的均匀尺寸的塑料颗粒。

此外,滚刀设计可以定制以满足特定的切割需求。为了保证切割效率和精度,作为塑料颗粒切割机制造商,我们建议当塑料颗粒切割机切割的塑料颗粒达到2000吨时就需要更换刀具。

塑料切条机参数

- 旋转刀片数:18齿

- 功率:2.2KW

- 容量:150公斤

- 尺寸:800*560*1150

- 旋转刀片数:22齿

- 功率:3.0KW

- 容量:250公斤

- 尺寸:800*560*1150

- 旋转刀片数:22齿

- 功率:3.0KW

- 容量:280公斤

- 尺寸:800*56081150

应用领域

塑料颗粒切割机适用于以下领域:

- 塑料回收厂:对废塑料进行造粒、再生。

- 塑料制品厂:生产注塑、吹塑、挤出等原料颗粒。

售后服务

我们提供全面的售后支持,包括:

- 安装调试:专业技术团队协助客户完成设备安装调试。

- 培训服务:为操作人员提供详细的使用、维护培训。

- 配件供应:长期供应优质刀片等配件。

- 技术支持:24小时在线服务,随时解决客户问题。