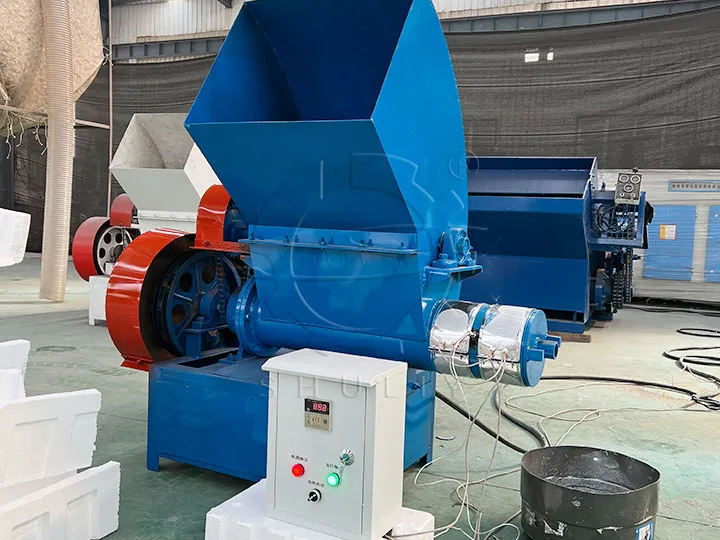

The EPS foam granulation line consists of five main single machines: plastic foam crusher, plastic foam extruder, cooling tank, EPS pellet cutting machine, and storage bin. It is a plastics solution designed for EPS foam recycling and the end product is plastic pellets with a production capacity of 100-500 kg per hour.

The EPE pelletizing process is slightly different from EPS, which we will introduce for you in detail next.

What Foams Can Be Pelletized?

Various types of foam materials can be pelletized, including expanded polystyrene (EPS), expanded polypropylene (EPP), and expanded polyethylene ( EPE). These foams usually include pearl wool, insulated boxes, disposable foam lunch boxes, foam cushions, foam packaging materials, foam fillers, etc.

By pelletizing these foams, they can be transformed into small, uniform pellets that are easier to handle, store, and reuse in the manufacturing of new products.

End Product – Foam Pellets

Expanded polystyrene recycling lines process waste foam material into high-quality plastic pellets. EPE and EPS pellets have a wide range of applications and can be reused to produce a variety of packaging materials, thermal insulation materials, filler materials, etc.

EPS Foam Granulation Process

The first step of EPS granulation is crushing, due to the large size of EPS foam, it needs to be crushed first to enter the granulator. The crushed foam blocks are transported to the hopper through the pipeline and then into the foam pelletizer to ensure that the material enters the granulation process smoothly.

泡沫回收的第二步是将破碎的泡沫块放入 泡沫造粒机 用于造粒。在这里,泡沫被熔化并挤出成塑料条。

第三步,将挤出的塑料条放入 冷却水箱 冷却并治愈。挤出的塑料条太热太软而无法切割,因此必须先冷却。

EPE Foam Pelletizing Process

Unlike EPS granulating, EPE material can go directly into the pelletizer, this is because EPE material is softer and the EPE foam granule machine comes with a feeding device to shred it. The subsequent steps are the same as for EPS pelletizing, the long plastic strips extruded from the pelletizer are cooled and cut into small pellets.

Video of EPE EPS foam granulation line

Recommended EPS Foam Compactor

The lightweight and expandable nature of EPS foam materials results in a large amount of space being taken up during foam recycling and storage. This is also a major problem in EPS foam recycling. To solve this problem, we recommend the use of a specialized foam compactor. It compresses the foam material and reduces its volume, thus reducing the cost of storage and transportation.

Shuliy 可以提供两种不同类型的泡沫压实机, 泡沫熔化机, 和 泡沫压实机 供您选择。它们都执行相同的压缩泡沫并减小其体积的功能。区别在于,一种需要热量,另一种则纯粹是物理压缩。

关于保丽龙片材造粒线的描述

| 发源地 | 中国 |

| 品牌 | 舒利 |

| 容量 | 100-500公斤/小时 |

| 保修单 | 1年 |

| 核心设备 | 泡沫破碎机、泡沫造粒机 |

In addition to pelletizing, we offer other EPS recycling solutions. For example, EPS is melted and extruded into ingot blocks using an EPS hot melting recycling machine, or EPS foam is compressed into blocks using a foam compactor. Both methods are effective in reducing the volume of EPS foam for storage, transportation, and subsequent processing. Our company can provide the right solution for your needs and offer customized services to ensure that your specific requirements are met.

EPS Foam Granulation Line Price Inquiry

我们拥有丰富的经验和专业团队,可以定制回收解决方案,帮助您实现可持续发展目标。如果您有其他想要回收的塑料,请联系我们为您推荐合适的回收机器。