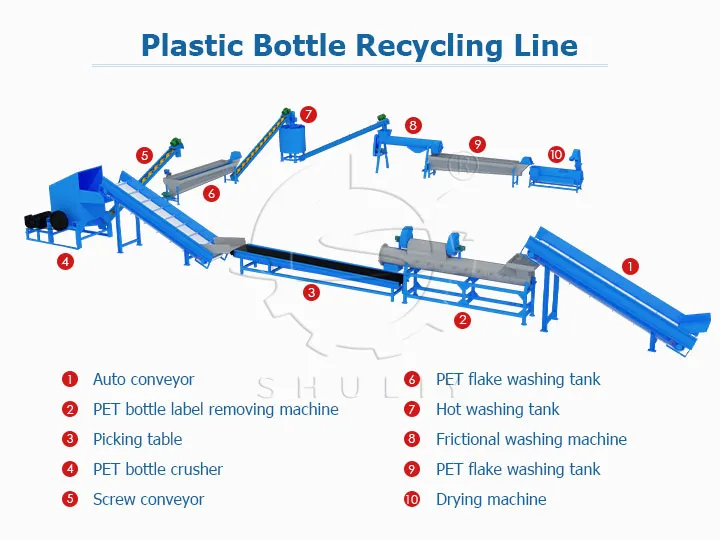

Laini ya kuosha chupa za PET ni laini kamili ya kuchakata inayoundwa na mashine kadhaa kuu kama vile kichungio cha chupa ya maji ya plastiki, mashine ya kuondoa lebo, mashine ya kuosha flakes ya plastiki, mashine ya kuondoa maji ya plastiki, na kadhalika. Kazi yake kuu ni kubadilisha taka za chupa za plastiki zilizorejeshwa kuwa flakes safi za PET kupitia msururu wa michakato. Kwa aina tofauti za chupa za plastiki na mahitaji ya usindikaji, Shuliy inaweza kubinafsisha muundo ili kukidhi matakwa yako mahususi ya kuchakata chupa.

Kwa nini Usafishaji Chupa za PET?

Urejelezaji wa chupa za PET una faida za moja kwa moja za kiuchumi kwa watayarishaji na watayarishaji. Wasafishaji wanaweza kuuza vipande vya chupa za PET vilivyochakatwa kwa wazalishaji kwa faida. Kwa wazalishaji, kutumia flakes za chupa za PET zilizorejeshwa badala ya malighafi mpya kunaweza kupunguza kwa kiasi kikubwa gharama za malighafi, hasa kuokoa pesa katika uzalishaji wa wingi. Ifuatayo, tutaanzisha jinsi ya kuchakata chupa za PET

Mchakato wa Uzalishaji wa chupa za PET

- Kuondoa lebo: Ondoa lebo kwenye uso wa chupa za PET.

- Kusagwa: Chupa za PET zilizo na lebo zilizoondolewa huvunjwa vipande vidogo.

- Mgawanyiko wa kofia na flakes: Kofia nyepesi hutenganishwa na flakes nzito kwa teknolojia ya kutenganisha inayoelea na kuzama.

- Kuosha moto: Tumia maji ya moto kuosha vipande vya chupa ili kuondoa mafuta na mabaki.

- Kusafisha Msuguano: Usafishaji zaidi wa msuguano huhakikisha uondoaji kamili wa uchafu.

- Kusuuza: Kusuuza kwa maji safi ili kuondoa visafishaji na uchafu uliobaki.

- Kukausha: Hatimaye, flakes za chupa zilizosafishwa hukaushwa ili kupata flakes kavu ya PET.

Malighafi Kwa Kiwanda cha Kusafisha Chupa ya PET

Malighafi kuu ya laini ya kuosha chupa za PET hutumiwa chupa za PET kama vile chupa za maji ya madini, chupa za vinywaji, chupa za cola, chupa za maziwa, vyombo vya plastiki, na kadhalika. Matofali ya chupa ya plastiki yaliyobanwa yanahitaji kufunguliwa kwa mashine ya kopo ya bale kabla ya kusagwa. Chupa hizi hukusanywa, kupangwa, na kisha kusindika kupitia mashine ya kuchakata chupa za plastiki. Bidhaa ya mwisho ya mchakato huu ni flakes safi za PET.

Vipande vya PET vya Ubora wa Juu

Rangi ya flakes ya chupa ya PET na ubora wa bidhaa ya mwisho huathiri bei yake. Kiwango cha juu cha kusafisha na usindikaji, uchafu mdogo, na bei ya juu ya flakes ya chupa za PET, na flakes za ubora wa juu kawaida ni ghali zaidi kuliko flakes za rangi.

Vipande vya chupa vinavyotengenezwa na mashine yetu ya kuchakata chupa za PET vinaweza kufikia kiwango cha ukavu, mnato wa tabia, thamani ya pH, na maudhui ya uchafu.

Utangulizi wa Mashine ya Kusafisha Chupa ya PET

Laini ya kuosha chupa za PET ina mashine kadhaa moja, ambayo kila moja ina jukumu tofauti, na hufanya kazi pamoja ili kukamilisha mchakato wa kuchakata na kuosha chupa za plastiki.

Kiondoa Lebo ya Chupa ya PET

Mashine ya kuondoa lebo ina blades nyingi za carbide ndani, ikiondoa 98% ya lebo za PVC na kupunguza maudhui ya PVC katika chips za chupa za PET.

PET Kusagwa Machine

Hatua inayofuata ilikuwa kutumia mashine ya kuponda PET kuponda chupa za plastiki kuwa vipande baada ya lebo kuondolewa. Baada ya mchakato wa kusafisha mfululizo, chips hizi zinakuwa bidhaa ya mwisho tunayohitaji——chips za chupa za plastiki zilizorejelewa.

Tangi ya Kuzama ya Plastiki ya Kuelea

Utenganishaji wa plastiki kwa kuzamisha na ku浮 unatumia wingi kutenganisha chips za chupa za PET kutoka kwa vizuizi vya chupa za PP. Chips za chupa huzama na kusafirishwa kwenye mchakato unaofuata, wakati kofia huzunguka na kutiririka nje.

Tangi ya Kuosha Maji ya Moto

tangi ya kuosha maji ya moto inaosha chips za chupa za plastiki kupitia maji ya joto la juu na sabuni za kemikali. Hii inatoa ufanisi katika kuondoa uchafu, mafuta, mabaki, na contaminant nyingine kutoka uso wa chips za chupa, kuhakikisha usafi wa chips za chupa za plastiki.

Mashine ya Kuosha ya Msuguano

washer ya msuguano inaondoa uchafu na sabuni za kemikali zilizounganishwa na chips za chupa ili kukidhi viwango vya kurejelewa kwa chips za chupa zilizokusanywa.

Mashine ya Kukausha Chips za Plastiki

Mashine hii ya kuondoa unyevu wa plastiki inaweza kuondoa 95%-98% ya maji, na kwa mabomba ya kukausha nyuma, maji yanaweza kudhibitiwa zaidi hadi 0.5-1%.

Video ya Laini ya Kuosha Chupa za PET

Maswali Yanayoulizwa Mara kwa Mara Kuhusu Mashine ya Kusafisha Chupa ya Plastiki

Je! Aina ya Pato ni Gani ya Kiwanda cha Kusafisha Chupa za Plastiki?

Pato la kawaida la mstari huu wa kuosha chupa za PET huanzia 500 kg / h hadi 6000 kg / h.

Je, ni Mahitaji Gani ya Eneo la Kiwanda kwa Njia hii ya Uzalishaji?

500 hadi 1000 mita za mraba. Mistari ya uzalishaji yenye kiasi kikubwa inahitaji eneo kubwa.

Jinsi ya Kufunga Mashine ya Kusafisha Chupa ya PET?

Tunatoa maagizo ya mtandaoni au usaidizi kwenye tovuti na usakinishaji.

Vifaa Vimesafirishwa Nchi Gani?

Laini yetu ya kuosha chupa za PET imesafirishwa kwenda Nigeria, Sudan Kusini, Msumbiji, Kongo, Kenya, Tanzania, Iraq, Saudi Arabia na nchi zingine.

Faida za Laini ya Kuosha Chupa ya Shuliy PET

- Vipande vya chupa za PET zinazozalishwa ni za ubora wa juu na zinaweza kutumika moja kwa moja katika uzalishaji wa bidhaa za plastiki.

- Laini nzima ya kuosha chupa za PET inasaidia muundo uliobinafsishwa, ambao unaweza kubadilika kwa urahisi kulingana na mpangilio wa mtambo wa mteja na mahitaji ya uzalishaji.

- Kwa kiwango cha juu cha automatisering, mstari wa uzalishaji wa 1000kg / h unahitaji tu shughuli za mwongozo 6-8, kwa kiasi kikubwa kupunguza gharama za kazi, huku kuboresha ufanisi wa uzalishaji.

Kurejeleza Onyesho la Mradi

Wateja kutoka Msumbiji, Kongo, na Kenya wamenunua laini za kuosha chupa za PET kutoka kwa kampuni yetu. Walikuwa wakikabiliwa na changamoto katika kuchakata taka za chupa za plastiki. Mashine yetu ya kuchakata chupa za plastiki iliwapatia suluhisho endelevu ambalo liliwasaidia kutatua tatizo hili.