Vor kurzem hat das von unserem indonesischen Kunden in unserem Unternehmen bestellte LDPE-Folienrecyclingmaschinenmaterial die Produktion abgeschlossen und kann nun an die Fabrik des Kunden versendet werden.

Der Kunde ist hauptsächlich im Kunststoffrecyclinggeschäft tätig und verfügt über drei Kunststoffgranulationslinien. Die diesmal angeschaffte Reinigungslinie dient hauptsächlich der Aufbereitung des zerkleinerten LDPE-Folienmaterials. Im Folgenden stellen wir Ihnen die individuellen Features und Lösungen der Reinigungslinie im Detail vor.

Maßgeschneiderte Anforderungen und Lösungen

Die maßgeschneiderte LDPE-Folienrecyclingmaschine besteht aus zwei Teilen: Waschen und Entwässern. Der Kunde forderte uns ausdrücklich auf, die Wäschelinie so anzupassen, dass das zerkleinerte LDPE-Folienmaterial ordnungsgemäß gereinigt und getrocknet wird. Die LDPE-Folienwaschanlage ist für die Verarbeitung von LDPE-Folienschnitzeln mit einer Größe von 1 cm ausgelegt. Um Materialverluste während des Waschvorgangs zu vermeiden, haben wir die Siebgröße der Zentrifugalentwässerungsmaschine speziell angepasst, um sicherzustellen, dass kein Material austritt.

Darüber hinaus stellt der Kunde strenge Anforderungen an den Trocknungsprozess. Deshalb haben wir nach der Entwässerungsmaschine eine Trocknungsleitung eingebaut. Diese Trocknungsleitung stellt sicher, dass der Feuchtigkeitsgehalt des Materials zwischen 0,5% und 1% liegt und damit den Trocknungsstandards des Kunden entspricht. Das Trocknungsrohr ist 20 Meter lang und hat einen Durchmesser von 279 mm, was eine effiziente und gleichmäßige Trocknung gewährleistet.

Details zur LDPE-Folienrecyclingmaschine

Unsere LDPE-Folienrecyclingmaschine nutzt fortschrittliche Wasch- und Trocknungstechnologie, um Verunreinigungen und Feuchtigkeit effizient aus dem Folienmaterial zu entfernen. Ob es sich um das Mischen der Materialien im Waschtank oder die Hochgeschwindigkeitszentrifugation in der Trocknungsmaschine handelt, alle Verbindungen sind sorgfältig konzipiert, um sicherzustellen, dass die verarbeiteten Materialien den von den Kunden geforderten Qualitätsstandards entsprechen.

- Mit Schneckenlader und Vertikalheber

- Größe des Waschtanks: L5m, B1,2m, H1,3m

- Wandstärke des Tanks: 3 mm

- Material: Kohlenstoffstahl

- Dicke der unteren Schraubenklinge: 6 mm

- Hauptleistung des Waschtanks: 5 kW

- Vertikalheber: 7,5 kW

Kunststoffflocken-Entwässerungsmaschine

- L: 3000 mm

- B: 850 mm

- Leistung: 30 kW

- 1500 U/min

- Netzmaterial: Edelstahl 304

Trockenrohr

- Rohrdurchmesser: 219 mm

- Rohrlänge: 20 m

- Rohrstärke: 2 mm

- Motorleistung: 15 kW

- Heizpulver: 30 kW

- Material: Edelstahl 201

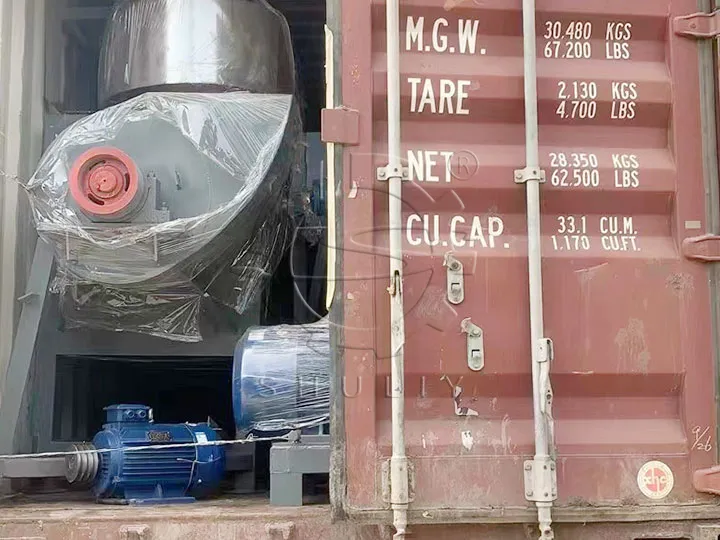

Versand der LDPE-Folienwaschanlage

Die Maschine ist jetzt bereit, an die Fabrik des Kunden in Indonesien versandt zu werden. Wir glauben, dass der Einsatz dieser LDPE-Folien-Recyclingmaschine dem Kunden ermöglichen wird, Kunststoffabfälle effizienter zu verarbeiten, die Produktionseffizienz zu verbessern und die Qualität des Endprodukts zu erhöhen.