The dry ice block making machine is a specialized piece of equipment designed to compress liquid or solid carbon dioxide into high-density dry ice blocks. It is widely used in cold chain logistics, food preservation, industrial cooling, stage effects, and commercial dry ice production.

Through a stable compression forming process, the machine can continuously produce dry ice blocks with uniform size, high density, and low sublimation loss, meeting the needs of users at different production scales.

According to output capacity and installation structure, dry ice block machines are available in standard models and vertical high-capacity models, suitable for applications ranging from small and medium production to industrial-scale continuous operation.

Working Principle of The Dry Ice Block Making Machine

The dry ice block machine uses liquid CO₂ or dry ice pellets as raw material. Under sealed conditions, the material is compressed by a mechanical or hydraulic system to form solid dry ice blocks.

During the compression process, CO₂ is rapidly solidified and pressed into high-density blocks, which are then demolded and discharged for subsequent conveying or packaging. No chemical additives are required throughout the process. The block density and dimensions are precisely controlled by machine parameters, ensuring compact structure and consistent size.

With optimized pressure and temperature control, the machine achieves a liquid-to-solid CO₂ conversion ratio of 42% or higher, helping reduce raw material loss while maintaining stable output.

Main Features of Our Dry Ice Block Machine

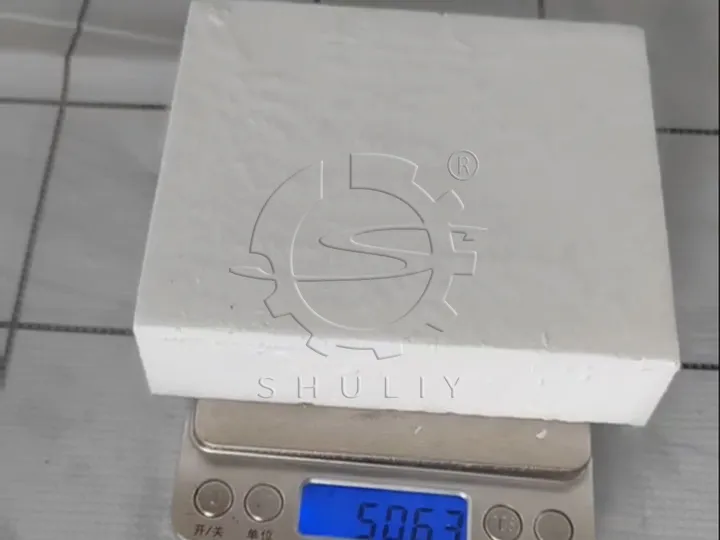

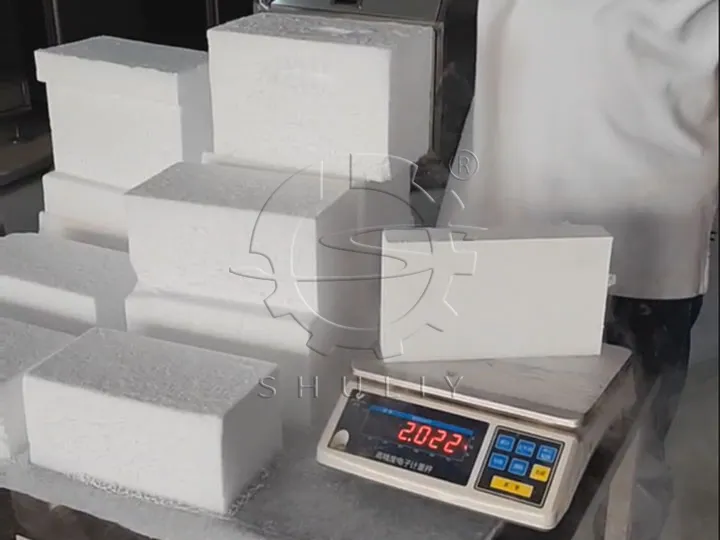

High dry ice density, slower sublimation: Dry ice density reaches 1450–1550 kg/m³, resulting in compact blocks with reduced sublimation during storage and transportation, ideal for medium- and long-distance use.

Stable CO₂ conversion efficiency: Liquid-to-solid CO₂ conversion ratio is ≥ 42%, contributing to lower production costs.

Wide output capacity range: Single-machine capacity ranges from 120 kg/h to 1000 kg/h, suitable for different production scales.

Flexible block specifications: Supports various block sizes and thicknesses, including 1 kg, 2 kg, 5 kg, and 10 kg blocks for direct use or sale.

Reasonable power configuration and stable operation: Total power consumption ranges from 4.5 to 5.5 kW, suitable for long-term continuous operation with controlled energy use.

Standard Dry Ice Block Making Machine

The standard dry ice block machine is designed for small to medium-scale dry ice block production. Its compact structure and small footprint make it suitable for startup projects or facilities with limited space.

This model offers an output of 120–180 kg/h, producing dry ice blocks with dimensions of 125 × 105 × (18–75) mm and a density of approximately 1550 kg/m³.

Total power consumption is 4.5 kW, machine weight is about 360 kg, and overall dimensions are 128 × 56 × 134 cm, making operation and maintenance straightforward.

Vertical Dry Ice Block Machines (Medium to High Capacity)

SL-500 Vertical Dry Ice Block Machine

The SL-500 vertical dry ice block making machine is suitable for customers requiring higher output and flexible block specifications. It provides a production capacity of 100–500 kg/h and produces blocks sized 250 × 140 × (20–210) mm, with dry ice density between 1450 and 1550 kg/m³.

It supports multiple block weights, including 1 kg, 2 kg, 5 kg, and 10 kg, allowing quick adaptation to downstream applications.

Total power is 5.5 kW, machine weight is approximately 900 kg, and overall dimensions are 150 × 80 × 228 cm, making it suitable for continuous operation in medium-scale projects.

High-Capacity Vertical Dry Ice Block Maker

This model is designed for industrial-scale dry ice block production, with a capacity of 800–1000 kg/h. Block size and density remain stable, and the liquid-to-solid CO₂ conversion ratio is not less than 42%.

The machine operates at 5.5 kW, weighs approximately 1950 kg, and has overall dimensions of 150 × 135 × 230 cm. It is typically integrated into complete dry ice block production lines for continuous and efficient operation.

应用领域

Dry ice block making machines are widely used in various industries and applications, including but not limited to:

- Cold chain logistics and food preservation: For low-temperature transportation and insulation of meat, seafood, fresh produce, and frozen foods.

- Pharmaceutical and biomedical industries: Storage and transportation of vaccines, medical products, and biological samples.

- Industrial cooling and equipment temperature control: Used for localized or temporary cooling in industrial processes.

- Stage effects and commercial applications: Stage fog effects, exhibitions, and entertainment uses.

- Dry ice production and distribution companies: For direct sale of dry ice blocks or further processing.

System Configuration and Expansion

In practical projects, the dry ice block making machine is commonly integrated with the following equipment to form a complete dry ice block production system:

- Dry ice pelletizer (upstream pellet production)

- Dry ice block machine (compression and forming)

- Conveying system

- Semi-automatic or automatic packaging equipment

The complete solution can be flexibly configured according to output requirements, plant layout, and automation level.

Dry Ice Making Machine For Sale

The dry ice block making machine is a key piece of equipment for achieving stable and efficient dry ice block production. By selecting the appropriate model and configuration, users can improve product quality while effectively reducing operating costs.

If you are planning a dry ice production project, please feel free to contact us for detailed technical specifications, model recommendations, and complete solutions.