Vipande vya chupa za PET ni nyenzo muhimu iliyosindikwa katika tasnia ya kuchakata tena plastiki na hutumiwa sana katika utengenezaji wa chupa mpya, vifaa vya ufungaji na nguo. Bei ya chupa za chupa hubadilika kadiri mahitaji ya soko yanavyobadilika. Kuelewa mambo muhimu yanayoathiri bei ya vipande vya PET husaidia watayarishaji na watayarishaji kufanya maamuzi sahihi wakati wa mchakato wa ununuzi na uuzaji.

Mchakato wa Usafishaji wa Chupa ya PET

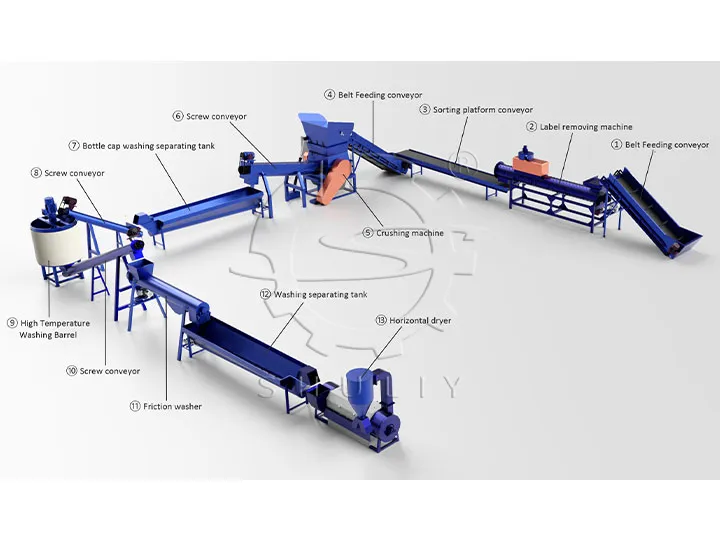

Processi wa kuchakata chupa za PET unajumuisha hatua kadhaa kama vile kuondoa lebo, kukata, kuosha, kutenganisha, kukausha, n.k., na ufanisi na ubora wa hatua hizi kwa kiasi kikubwa unategemea vifaa vya kuchakata chupa za PET vinavyotumika.

Vifaa vya kuchakata vyema vinaweza kuchakata kwa haraka kiasi kikubwa cha chupa za PET ili kuzalisha flakes za ubora wa juu, kuongeza ufanisi wa uzalishaji, na kupunguza gharama za utupaji. Vifaa vya teknolojia ya juu huondoa uchafu zaidi na kuboresha usafi wa flakes, na kusababisha bei ya juu katika soko.

Rangi ya Flakes za chupa za PET zilizosindikwa

Rangi ya chupa za PET ni jambo muhimu linaloathiri bei yao. Vipuli vya chupa vya uwazi au vya rangi nyepesi vina bei ya juu kutokana na matumizi yao makubwa na mahitaji makubwa; kijani, bluu, na flakes za rangi nyingine zina maombi mdogo na bei ya chini; na flakes za rangi nyeusi au tofauti zina usafi wa chini, matumizi machache, na bei ya chini zaidi.

Mahitaji ya Soko

Mahitaji ya soko ya nyenzo za PET zilizorejeshwa huathiri moja kwa moja bei za chupa za chupa. Nyenzo za PET zilizorejeshwa hutumika sana katika utengenezaji wa chupa mpya, vifungashio na nguo, na bei hupanda mahitaji yanapoongezeka na kushuka mahitaji yanapopungua au ugavi unatosha. Mahitaji ya msimu, mabadiliko ya kiuchumi, na mabadiliko ya sera pia huathiri mahitaji ya soko.

Bei za Malighafi

Bei ya PET flakes inahusishwa kwa karibu na bei ya vifaa vya bikira vya PET. Wakati bei ya nyenzo mbichi inapopanda, flakes za PET zilizorejelewa huwa njia mbadala ya gharama nafuu, inayoongeza mahitaji na bei.

Kinyume chake, wakati bei ya vifaa vya bikira inaposhuka, makampuni huwa na kupendelea kutumia nyenzo mpya, kupunguza mahitaji ya flakes recycled na kupunguza bei. Kwa hivyo, kushuka kwa bei ya malighafi huathiri moja kwa moja bei ya chupa za PET.

Gharama za Usindikaji

Kuchakata na kusindika PET mchanganyiko wa chupa unajumuisha hatua kama vile kuondoa lebo, kufinya, kuosha, na kukausha, ambazo zinatumia gharama za kazi, nishati, na matengenezo ya vifaa, ambazo zinaathiri bei ya mchanganyiko wa chupa. Ikiwa gharama za umeme, kazi, au matengenezo zinaongezeka, kampuni kawaida hupitisha gharama hizo kwa bei ya chupa, hivyo ufanisi wa uzalishaji na kuboresha mchakato pia kuna athari kwenye bei.