Konsumsi daya mesin pembuat butiran plastik menjadi perhatian banyak produsen. Saat ini, produsen granulator limbah plastik berbagi dengan Anda beberapa informasi tentang konsumsi daya mesin pembuat butiran plastik.

Butiran plastik membuat konsumsi daya mesin

Konsumsi daya mesin pelet ekstrusi terkait dengan total kapasitas terpasang, koefisien konsumsi daya, bahan baku, desain mesin, pengoperasian, dan faktor lainnya. Total kapasitas terpasang biasanya diperoleh dengan menjumlahkan seluruh daya motor dan daya pemanas granulator limbah plastik. Konsumsi daya per jam dari mesin pelet ekstrusi dapat diperkirakan berdasarkan koefisien konsumsi daya 0,3~0,55. Misalnya, jika total kapasitas terpasang adalah 120kw, konsumsi daya per jam dapat berkisar antara 120kw*0,3 dan 120kw*0,55. Yaitu 36 derajat hingga 66 derajat.

Ekspresi lain untuk konsumsi daya

Cara lain untuk mengekspresikan konsumsi listrik dari mesin pembuat bijih plastik adalah dalam satuan ton listrik yang dikonsumsi. Ton konsumsi listrik untuk plastik yang berbeda umumnya berkisar antara 280 kWh hingga 600 kWh. Dan ton konsumsi listrik dari sebagian besar mesin pelletizing ekstrusi adalah sekitar 300 derajat.

Bagaimana cara menghemat listrik pada granulator limbah plastik?

Konsumsi daya aktual mesin pembuat butiran plastik sangat dipengaruhi oleh kadar air dan kandungan pengotor bahan baku. Desain mekanis yang baik, pemrosesan dan perakitan presisi tinggi, penerapan konverter frekuensi, dan penggunaan elemen pemanas yang wajar dapat mengurangi konsumsi daya. Produksi tanpa henti di segala cuaca, pekerja terampil, dan pengaturan kontrol suhu yang wajar juga merupakan cara yang efektif untuk mengurangi konsumsi daya.

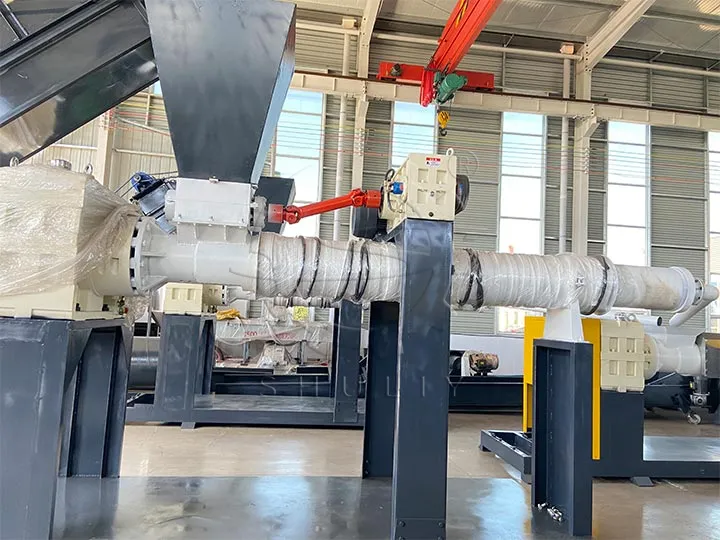

Mesin pembuat butiran plastik Shuliy secara aktif mengeksplorasi pengembangan mesin pelet ekstrusi hemat daya melalui keunggulan teknisnya. Dibandingkan dengan mesin pelet ekstrusi dengan spesifikasi yang sama, satu ton konsumsi listrik dapat dihemat sekitar 20%.