Mesin pelet EPE merupakan mesin daur ulang busa yang digunakan untuk mengolah bahan busa Expanded Polyethylene (EPE) menjadi bentuk pelet. Ini mengubah busa EPE menjadi bahan pelet yang dapat digunakan kembali melalui serangkaian langkah proses, termasuk pengumpanan, pemanasan, ekstrusi, dan pencetakan.

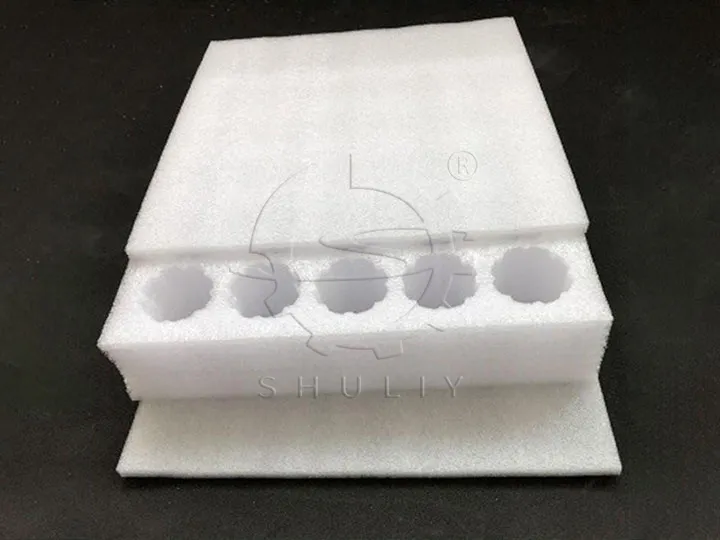

Apa itu bahan EPE?

EPE, atau Extended Polyethylene, adalah bahan busa yang ringan dan fleksibel yang umum digunakan dalam pengemasan, bantalan, dan insulasi. Bahan ini dikenal karena sifat penyerap guncangan dan tahan lembap yang sangat baik, menjadikannya pilihan populer untuk berbagai aplikasi. Kapas mutiara EPE, lembaran busa EPE, dan bahan pengemas EPE umum dapat digunakan sebagai bahan baku untuk granulator busa EPE.

Keuntungan dari Granulator Busa Shuliy EPE

- Pemrosesan yang efisien: dirancang khusus untuk menangani busa EPE, memastikan proses granulasi yang efisien.

- Pelet berkualitas tinggi: pelet yang dihasilkan seragam, berkualitas tinggi, dan memenuhi standar penggunaan kembali.

- Kemampuan penyesuaian: Berbagai model dan spesifikasi tersedia sesuai dengan kebutuhan pelanggan.

- Sistem pemberian makan yang kuat: memastikan pengumpanan material lancar dan meningkatkan efisiensi produksi.

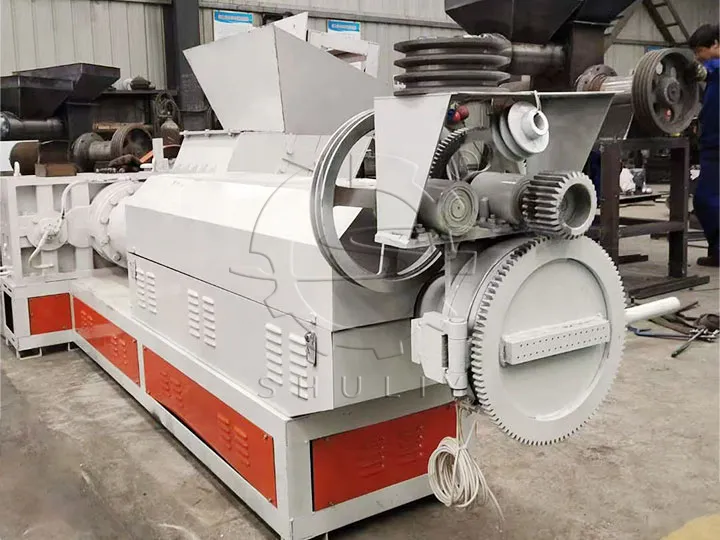

Struktur mesin pelet EPE

Struktur granulator EPE terdiri dari beberapa bagian penting, antara lain saluran masuk umpan, perangkat pembuangan, perangkat pemanas, kepala cetakan, dan kabinet listrik kontrol.

- Saluran masuk: Saluran masuk dirancang untuk dengan mudah memasukkan bahan busa EPE ke dalam mesin.

- Ventilasi: efektif menghilangkan gas yang dihasilkan selama proses.

- Bagian Pemanas: Unit pemanas memanaskan bahan plastik untuk melelehkannya dan memenuhi persyaratan pembuatan pelet.

- Die Head: Kepala die bertanggung jawab untuk mengekstrusi bahan cair menjadi bentuk pelet tertentu.

- Kabinet Distribusi Daya: menyediakan fungsi operasional dan pemantauan untuk memastikan pengoperasian seluruh alat berat secara efisien dan stabil.

Bagaimana Cara Kerja Granulator Busa?

Proses kerja granulator busa terutama dibagi menjadi beberapa langkah. Pertama, melalui perangkat pengumpanan paksa, bahan busa EPE dimasukkan secara merata ke dalam granulator.

Selanjutnya, alat pemanas di dalam mesin memanaskan material hingga menjadi cair.

Kemudian, sekrup yang berputar mendorong EPE cair ke kepala cetakan, melalui mana strip kontinu diekstrusi. Selama proses ini, alat pembuangan mengeluarkan gas berlebih untuk memastikan kualitas pelet.

Terakhir, EPE cair didinginkan dan dipotong menjadi pelet seragam oleh mesin pemotong pelet. Seluruh proses efisien dan stabil, memastikan kualitas produk akhir.

Video Kerja

Parameter granulator busa EPE

Bagaimana cara memilih mesin pelet EPE yang tepat?

Memilih mesin granulasi polietilen diperluas yang tepat bergantung pada berbagai faktor, termasuk jumlah busa EPE yang akan diproses, ukuran pelet yang dibutuhkan, dan pertimbangan anggaran. Berikut beberapa pertimbangan utama:

| Kapasitas | Pilihlah mesin pelletizer EPE dengan kapasitas yang sesuai dengan kebutuhan produksi Anda. Model mesin yang berbeda menawarkan opsi kapasitas yang berbeda, jadi evaluasi kebutuhan Anda dengan cermat. |

| Ukuran pelet | Pastikan kepala cetakan mesin granulasi polietilen yang diperluas dapat menghasilkan berbagai ukuran pelet yang Anda butuhkan. |

| Efisiensi energi | Pilih mesin pelet busa plastik dengan efisiensi energi tinggi untuk mengurangi biaya pengoperasian. |

| Kemudahan Perawatan | Pertimbangkan mesin pelet EPE yang mudah diservis untuk perawatan rutin. |

| Layanan purna jual | Pastikan Anda mendapatkan dukungan teknis, pemeliharaan, dan layanan lainnya tepat waktu dari produsen granulator busa EPE setelah pembelian. |