泡沫塑料压缩机是专门用于加工EPS(聚苯乙烯泡沫塑料)的专用设备,旨在有效减少泡沫材料的体积。该设备通过高压将EPS泡沫压缩成紧密的块体,以便于储存和运输。

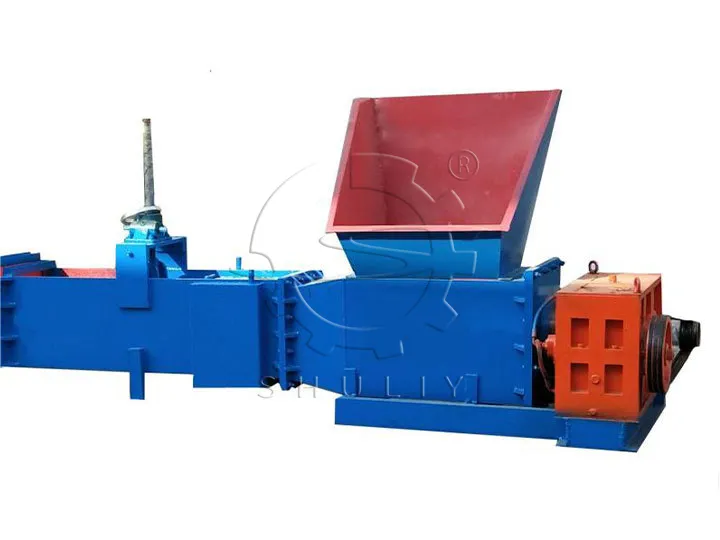

泡沫塑料压实机介绍

EPS压缩机的结构通常由入口、压缩室和出口组成,操作方便,适合各种规模的回收作业。其高效的压缩能力不仅降低了运输成本,而且提高了回收效率,使其成为泡沫回收行业中不可或缺的重要设备。通过使用冷压机,公司可以有效管理泡沫废物并重复利用资源。

值得一提的是,EPS泡沫压实机在压缩泡沫时不需要高温处理,这是它与泡沫熔融机的主要区别。

EPS压实机的优点

- 高压缩比:EPS泡沫可有效压缩成致密块或板,压缩比高达40倍,大大减小体积。

- 无异味:采用冷压方式,工作过程中不会产生异味。

- 易于维护:EPS泡沫压实机结构简单。维护和保养相对容易,可以降低维护成本。

- 节省空间:压缩块占用的存储空间更少,更易于管理。

- 降低运输成本:通过减少运输过程中所需的空间来降低总体运输成本。

EPS泡沫压实机如何工作?

- 首先,将废旧泡沫材料放入EPS泡沫塑料回收压缩机的入口。

- 破碎装置将EPS泡沫破碎成小块。

- 泡沫塑料压实机已启动。机械装置或液压系统开始对泡沫施加均匀且连续的压力。

- 在持续的压力下,泡沫材料逐渐被压缩成更致密的块或板。

- 压缩后的泡沫块或板可以从泡沫压实机的排出口取出,以便随后储存、运输或再加工。

EPS压实机工作视频

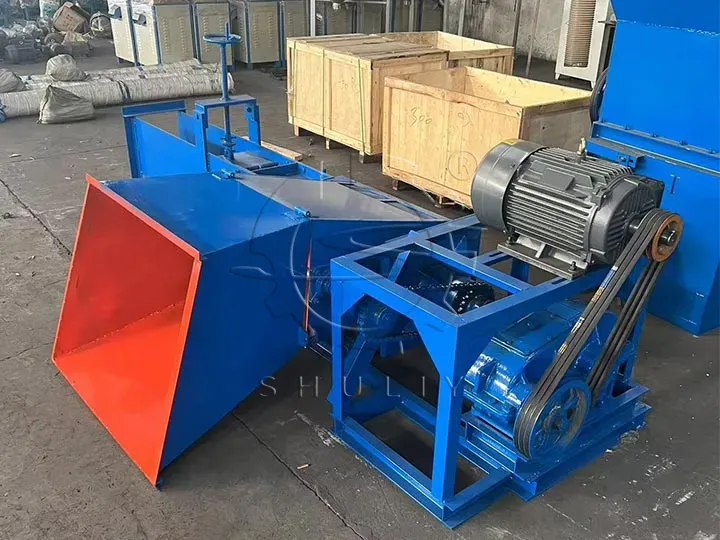

2 种密实机

我们提供立式和卧式两种类型的致密机。立式EPS保丽龙压实机采用顶部进料方式,操作方便,适合空间狭小的场合;卧式泡沫压实机采用侧进料方式,进料口与地面齐平,便于快速投放物料。这两种设计各有优点,您可以根据自己的具体需求选择合适的设备。

立式EPS泡沫压实机

泡沫塑料压实机参数

| 模型 | 260 | 300 | 350 | 400 |

| 功率(千瓦) | 7.5 | 11 | 11 | 15 |

| 压缩率 | 40:01:00 | 40:01:00 | 40:01:00 | 40:01:00 |

| 输入尺寸(mm) | 600*800*1400 | 600*800*1400 | 800*900*1400 | 800*900*1600 |

| 输出尺寸(mm) | 260*260 | 280*280 | 350*350 | 400*400 |

| 容量 | 400-600 | 400-600 | 600-800 | 800-1000 |

| 重量 | 600 | 700 | 800 | 1200 |

成功案例

我们的一位来自马来西亚的客户面临着处理大量泡沫废物的问题。这些泡沫废料在运输和储存过程中占用了大量空间,给回收带来了很大困难。经过Shuliy专业团队的咨询和分析,我们向客户推荐了我们的泡沫压实机来解决这个问题。

客户使用EPS泡沫压实机后,泡沫体积明显减少。这使他们能够更有效地储存和运输废物,从而节省大量资源和成本。

更多详情:发往马来西亚的EPS泡沫压实机