発泡スチロールコンパクターは、EPS (ポリスチレンフォーム) を処理するために設計された特殊な装置で、発泡材料の体積を効果的に減らすように設計されています。この装置は、EPS フォームを高圧で緻密なブロックに圧縮し、保管や輸送を容易にします。

発泡スチロールコンパクターの紹介

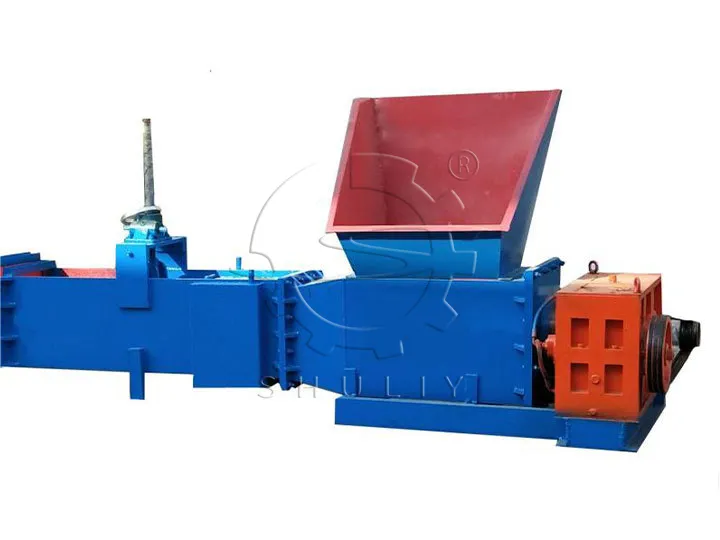

EPS コンパクターの構造は通常、入口、圧縮室、出口で構成されているため、操作が簡単で、あらゆる規模のリサイクル作業に適しています。その効率的な圧縮能力により、輸送コストが削減されるだけでなく、リサイクル効率も向上するため、フォームリサイクル業界において重要かつ不可欠な機器となっています。コールドコンパクターマシンを使用することで、企業は発泡廃棄物を効果的に管理し、資源を再利用できます。

EPS発泡スチロール圧縮機は、フォームを圧縮する際に高温処理を必要としないことが注目に値します。これが、フォーム溶融機との主な違いです。

EPSコンパクターのメリット

- 高い圧縮率: EPS フォームは 40 倍の高い圧縮率で高密度のブロックまたはボードに効果的に圧縮でき、体積を大幅に削減します。

- 臭いがない:コールドプレス方式を採用しており、作業過程で異臭が発生しません。

- メンテナンスが簡単:EPSフォームコンパクターの構造はシンプルです。メンテナンスや維持管理が比較的容易であり、維持費を削減できます。

- 省スペース: 圧縮されたブロックは、必要なストレージ容量が少なくなり、管理が容易になります。

- 輸送コストの削減: 輸送中に必要なスペースを削減することで、全体的な輸送コストを削減します。

EPSフォームコンパクターはどのように機能しますか?

- まず、廃発泡材をEPS発泡スチロールリサイクルコンパクターの入口に投入します。

- 粉砕装置は EPS フォームを細かく粉砕します。

- 発泡スチロールの圧縮機が作動します。機械装置または油圧システムがフォームに均一かつ継続的な圧力を加え始めます。

- 継続的な圧力下で、フォーム材料は徐々に圧縮されて、より密度の高いブロックまたはスラブになります。

- 圧縮された発泡ブロックまたはボードは、その後の保管、輸送、または再処理のために発泡圧縮機の排出ポートから取り外すことができます。

EPSコンパクターマシンの動作ビデオ

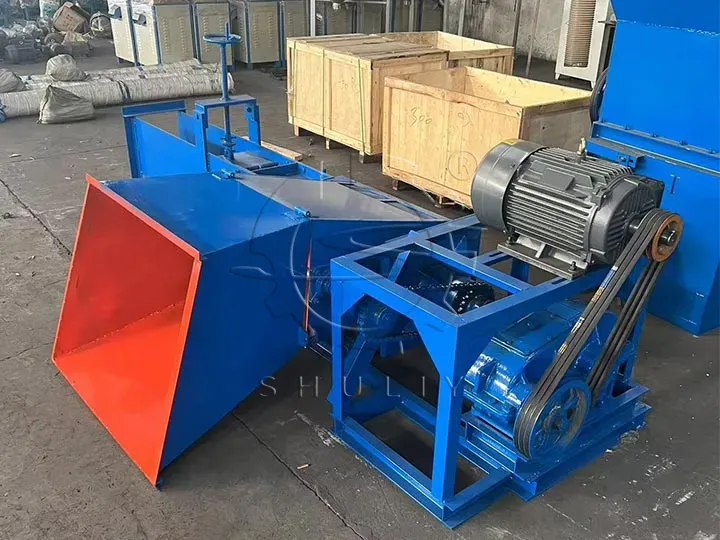

2種類のデンシファイアーマシン

当社では縦型と横型の 2 種類のデンシファイアーマシンを提供しています。縦型EPS発泡スチロールコンパクターは上送り方式を採用しており、操作が簡単で狭いスペースでの使用に適しています。一方、横型フォームコンパクターは側面供給方式を採用しており、入口が地面と同じ高さにあるため、材料を迅速に配置するのに便利です。これら 2 つの設計にはそれぞれ利点があり、特定のニーズに応じて適切な機器を選択できます。

縦型 EPS発泡スチロール圧縮機

発泡スチロールコンパクターのパラメータ

| モデル | 260 | 300 | 350 | 400 |

| 電力(kW) | 7.5 | 11 | 11 | 15 |

| 圧縮率 | 40:01:00 | 40:01:00 | 40:01:00 | 40:01:00 |

| 入力サイズ(mm) | 600*800*1400 | 600*800*1400 | 800*900*1400 | 800*900*1600 |

| 出力サイズ(mm) | 260*260 | 280*280 | 350*350 | 400*400 |

| 容量 | 400-600 | 400-600 | 600-800 | 800-1000 |

| 重さ | 600 | 700 | 800 | 1200 |

成功事例

マレーシアからの当社のお客様の 1 人は、大量の発泡廃棄物の処理という問題に直面していました。これらの発泡廃棄物は輸送や保管の際に多くのスペースを占めるため、リサイクルが非常に困難でした。 Shuliy の専門チームによる相談と分析の後、この問題を解決するために当社の発泡スチロール コンパクターをお客様にお勧めしました。

お客様は、EPS フォームコンパクターを使用した後、フォームの量を大幅に削減しました。これにより、廃棄物の保管と輸送をより効率的に行うことができ、資源とコストを大幅に節約できました。

詳細については、マレーシアに送られたEPS発泡スチロール圧縮機をご覧ください。