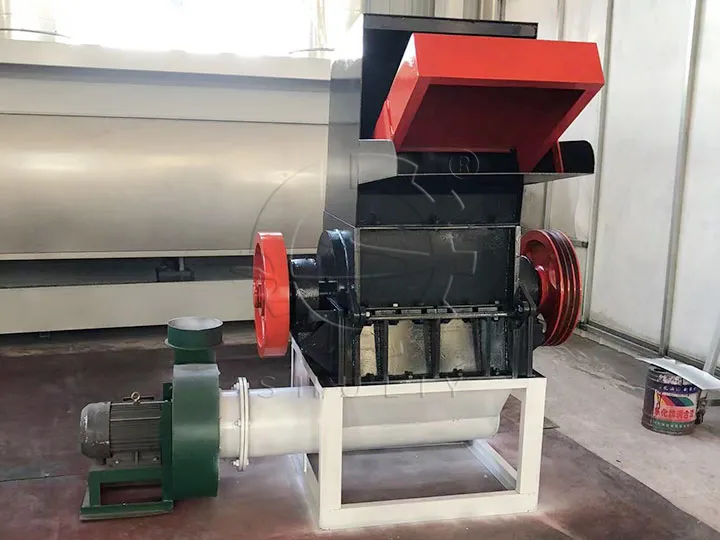

Penghancur plastik industri adalah peralatan penting dalam daur ulang plastik. Namun, pengoperasian dengan beban tinggi dalam jangka waktu lama akan mempercepat keausan mesin penghancur plastik skala kecil dan mengurangi masa pakai. Lantas, bagaimana cara mengurangi beban penghancur plastik industri dalam proses penggunaannya? Teruslah membaca.

Sumber beban penghancur plastik industri

Dalam rotasi normal sabuk dari penghancur plastik skala kecil, pisau bergerak dan pisau tetap dari poros utama dapat memotong plastik menjadi potongan kecil dan kemudian disaring oleh layar. Jika material tidak merata dan lebih, ini akan menyebabkan penyumbatan layar. Ini akan membebani mesin penghancur grinder plastik dan berdampak besar pada motor, pulley, dan drive pulley. Hal ini menyebabkan peningkatan arus dan panas dari motor penghancur plastik industri, dan mempercepat keausan sabuk dan pulley.

Cara untuk mengurangi beban penghancur plastik skala kecil

Pembersihan layar secara teratur

Layar merupakan komponen inti dari mesin penghancur penggiling penghancur plastik, namun akan menumpuk sejumlah besar residu dan kotoran setelah digunakan dalam waktu lama, sehingga mengakibatkan peningkatan beban peralatan. Pembersihan layar secara teratur dapat secara efektif mengurangi beban penghancur plastik industri dan memastikan efisiensi penghancuran.

Penyesuaian laju pengumpanan material

Kecepatan pasokan material yang terlalu cepat dapat menyebabkan penghancur plastik skala kecil beroperasi dalam kondisi kelebihan beban dan meningkatkan beban peralatan. Oleh karena itu, atur kecepatan pasokan material secara wajar sesuai dengan model penghancur plastik industri dan kapasitas pemrosesan untuk menghindari kelebihan beban.

Penggunaan kopling hidrodinamik

Menambahkan coupler hidrolik pada perangkat transmisi mesin penghancur penggiling plastik dapat memainkan peran perlindungan tertentu dalam kelebihan beban motor. Coupler fluida dapat berakselerasi secara perlahan saat penyalaan, mengurangi dampak penyalaan mendadak pada peralatan dan menurunkan beban.