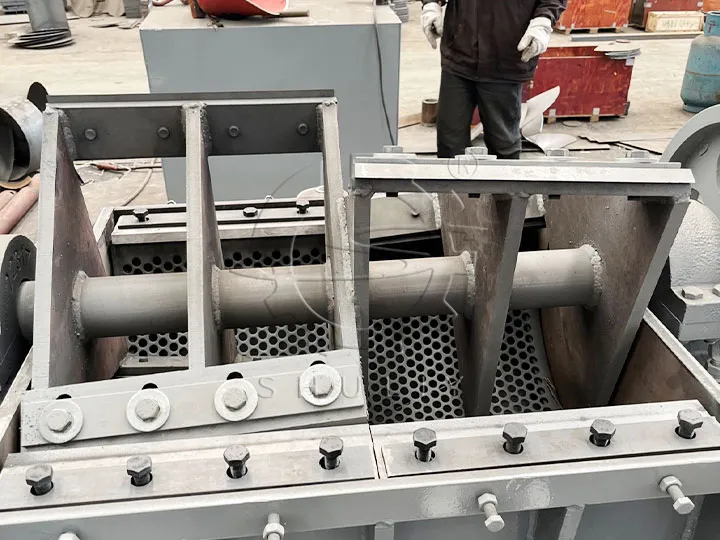

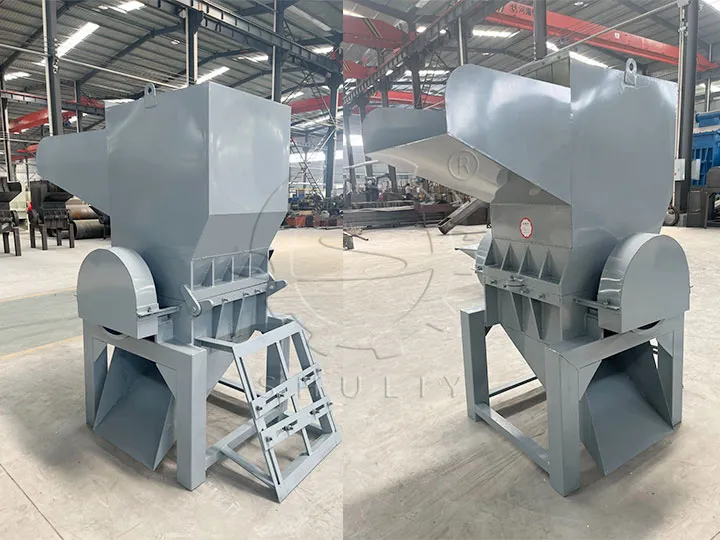

Pisau bermotor penghancur botol air plastik dan pisau tetap merupakan bagian penting dari peralatan. Ini memiliki dampak penting pada kinerja dan efisiensi crusher. Pisau bergerak dan pisau tetap adalah bagian kerja utama dari penghancur plastik. Dengan bekerja sama, mereka memotong dan menghancurkan plastik menjadi partikel yang lebih kecil.

Keuntungan menggunakan pisau bergerak dan pisau tetap penghancur plastik secara bersamaan terutama tercermin dalam aspek-aspek berikut.

Sangat mudah beradaptasi

Dengan menyesuaikan sudut dan posisi pisau tetap, alat ini dapat lebih baik disesuaikan dengan berbagai jenis bahan plastik dan kebutuhan penghancuran yang berbeda. Hal ini memungkinkan penghancur botol air plastik untuk digunakan lebih luas dalam penghancuran dan daur ulang berbagai produk plastik.

Misalnya, untuk plastik keras, sudut dan posisi pisau tetap pada mesin penghancur botol plastik perlu disesuaikan untuk meningkatkan kekuatan dan efek penghancuran. Untuk plastik lunak, sudut dan posisi pisau tetap penghancur botol susu plastik perlu disesuaikan untuk mengurangi kekuatan dan efek penghancuran.

Peningkatan efisiensi penghancuran

Pisau tetap yang dapat disesuaikan dapat mengontrol ukuran partikel dan efek penghancuran dengan lebih baik selama proses penghancuran. Untuk produk plastik yang perlu dihancurkan menjadi partikel-partikel kecil, sudut dan posisi pisau tetap mesin penghancur botol air plastik dapat diatur agar ukuran penghancuran lebih seragam dan halus.

Perawatan dan penyesuaian yang mudah

Desain pisau yang dapat digerakkan dan diperbaiki membuat perawatan dan penyesuaian mesin penghancur botol air plastik menjadi lebih mudah dan cepat. Jika pisau tetap aus atau rusak, pisau tersebut dapat dengan cepat disesuaikan atau diganti tanpa harus mengganti seluruh penghancur, sehingga menghemat biaya.

Selain itu, desain pisau bergerak dan tetap yang dapat disesuaikan memungkinkan penyesuaian parameter botol plastik penghancur dengan mudah untuk memenuhi kebutuhan produksi yang berbeda.