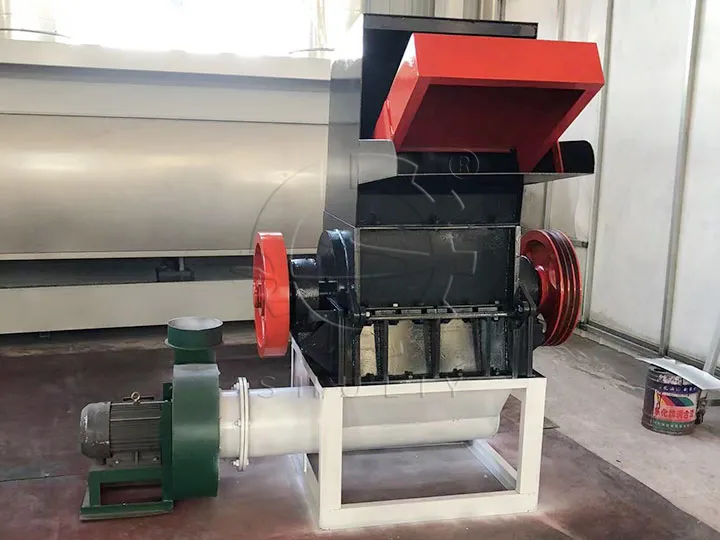

Penghancur skrap plastik terutama terdiri dari saluran masuk umpan, pemotong penghancur, saringan, saluran masuk pembuangan, dan motor. Bagian intinya adalah bilah penghancur. Ini terdiri dari satu set bilah berputar berkecepatan tinggi, dan bentuk serta kecepatan bilah akan mempengaruhi efek penghancuran.

Prinsip kerja mesin penghancur sampah plastik

Prinsip kerja dari penghancur limbah plastik adalah menggerakkan pemotong penghancur untuk berputar dengan kecepatan tinggi melalui motor listrik untuk menghancurkan produk plastik yang masuk ke port peng喂. Di bawah dampak kecepatan tinggi dan efek geser dari pisau, produk plastik secara bertahap dihancurkan menjadi potongan kecil. Setelah disaring melalui layar, butiran plastik yang dihancurkan akan keluar dari port pembuangan sesuai dengan ukuran yang diinginkan.

Kontribusi mesin penghancur plastik mini terhadap industri

Penghancur plastik mini adalah peralatan penting dalam industri daur ulang dan penggunaan kembali plastik. Kinerja dan kualitasnya secara langsung mempengaruhi produktivitas dan kualitas produk seluruh industri. Di masa depan, dengan kemajuan dan inovasi teknologi yang berkelanjutan, mesin penghancur plastik mini akan memainkan peran yang lebih penting. Penghancur sampah plastik untuk mempromosikan pengembangan industri daur ulang dan penggunaan kembali plastik untuk memberikan kontribusi yang lebih besar.

Pentingnya mesin penghancur sampah plastik terhadap lingkungan

Dengan meningkatnya kekhawatiran terhadap polusi plastik, penerapan penghancur botol plastik berukuran besar memiliki prospek yang luas. Di masa depan, penghancur botol plastik besar akan berkembang ke arah penghematan energi dan perlindungan lingkungan. Pada saat yang sama, dengan terus bermunculannya teknologi baru dan material baru, kinerja dan efisiensi mesin penghancur plastik mini juga akan terus ditingkatkan.